prefabricated building systems and steel building packages American standard

| Min. Order: | 120 Metric Ton |

|---|---|

| Trade Term: | CIF |

| Payment Terms: | T/T |

| Supply Ability: | 3000 Ton/per Week |

| Place of Origin: | Shandong |

Company Profile

| Location: | Binzhou, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 1-365 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | HX |

| Material Grade: | Grade Q345, equivalent to ASTM A572 |

| Top client Serviced: | SIEMENS, American GE, FRANCE ALSTOM, French energy power, Vale of Brazil |

| Standard: | AISI, ASTM, BS, DIN, GB, JIS Australian standard American standard |

| Surface Treatment: | Shot blasting then anti-rust paint or hot dip galvanize |

| Shipment by: | Container |

| Production Capacity: | 3000 Ton/per Week |

| Packing: | Panel accessories will be packaged in wooden box |

| Delivery Date: | 30 days |

Product Description

1. Specifications for the prefabricated building systems ( made of steel frame ) :

Items | Specification |

Length | Single slope , double slope , muti slope |

Width | Single span , double-span , Multi-span |

Height | single floor , double floors |

Column | Q235 , Q345 welded H section steel |

Beam | Q235 , Q345 welded H section steel |

Purlin | Q235 C channel or Z channel |

Knee brace | Q235 angle steel |

Vertical and traversal support | Q235 angle steel , round bar or steel pipe |

Tie bar | Q235 steel pipe |

Brace | Q235 round bar |

Cladding system | EPS , PU , Fiber glass wool sandwich panels or corrugated steel sheet with fiber glass wool insulation . available in Different colors & gauge |

Partition wall | sandwich panels ( EPS , PU , Fiber glass wool etc . ) available in Different colors & gauges |

Door | sandwich panel sliding door or roller door |

Gutter | stainless steel or color steel sheet |

Rainspout | PVC |

Live load on roof | In 120kg / Sqm ( Color steel panel surrounded ) |

Wind resistance grade | 12 grades |

Earthquake-resistance | 8 - 9 grades |

Structure usage | Up to 50 years |

Finishing options | vast array of colors and textures available |

Paint Options | Gray paint , red paint , white paint , epoxy zinc etc . Or Galvanized |

2. Company Data:

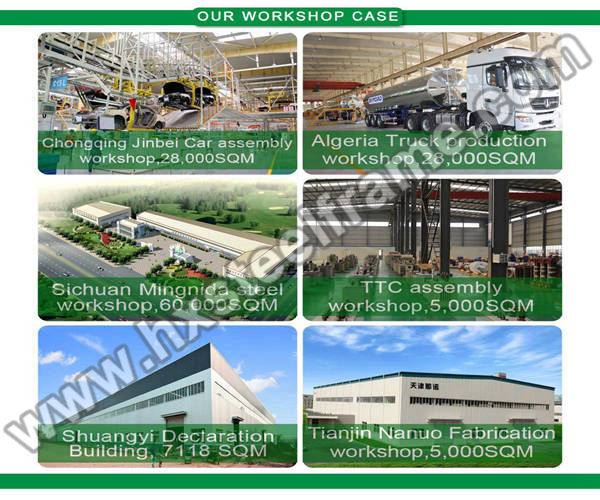

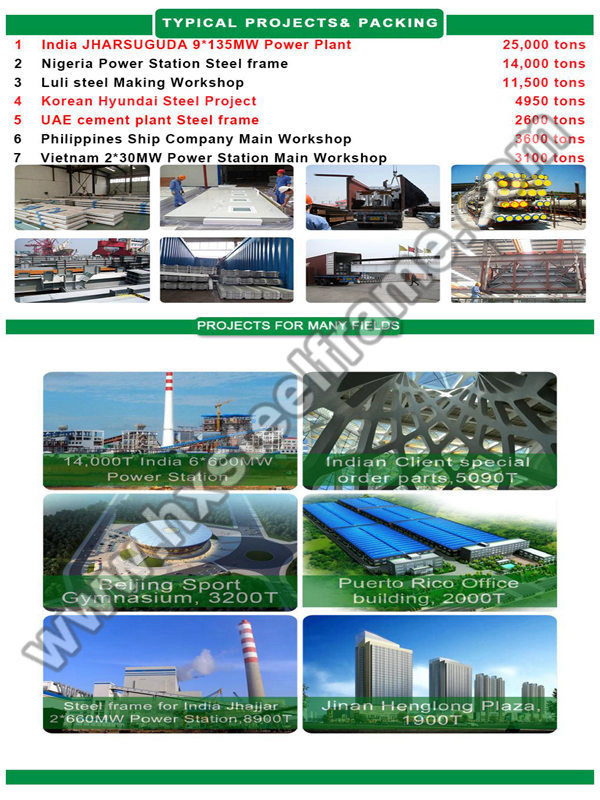

We have been focused on providing integrated steel structure and steel building solutions for the construction builders, design institutes, developers and construction material traders. Established in Shandong, our professional products and services have reached more than 100 countries and regions around the world. We mainly provides major steel structure and steel building solutions including Steel Structure Building,steel workshop& warehouse, Multi-story Building. Currently we have founded branch office and factory in many areas, with over 960 employees worldwide. And the production base is located at Shandong, China. We applies industry-leading environmentally friendly green materials, the world' s leading structural design. Our R&D center was established in Beijing and has applied more than 50 patents including 2 innovation patents up to now. Backed up with over 80 talented engineers in steel structural and architectural design.

3. Project case- Shandong Weifang Metal Logistics Co., Ltd light steel structure warehouse, 17000 SQM:

Type: Welded H-Section Steel

Forming: Hot-Rolled Steel

Crane:with or Without(1 to 50 Tons)

External Wall Design: EPS/ Rock Wool/ Polyurethane/ MGO/ Cement Foam Panel

Life Time of Steel Frame:More Than 50 Years

Packing Method: Flat Pack, Open Top Container, by Steel Skid, etc.

Raw Materials: Q235/ Q345

Door: Sliding Door, Roller Door, Steel Door etc.

Window: PVC, Aluminium( Sliding and Fix)

4. DESIGN STANDARD& SOFTWARE for prefabricated building systems ( made of steel frame ) :

Standard: America Standard, Australia Standard, England Standard, China Standard, etc.

Software: SAP2000, Auto CAD, PKPM, RSTAB, PROE, MTS, Tekla Structures( Xsteel) , 3D3S, Tarch, etc.

5. Our seaworthy packing system for prefabricated building systems ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) Common type of the industrial building you supply ?

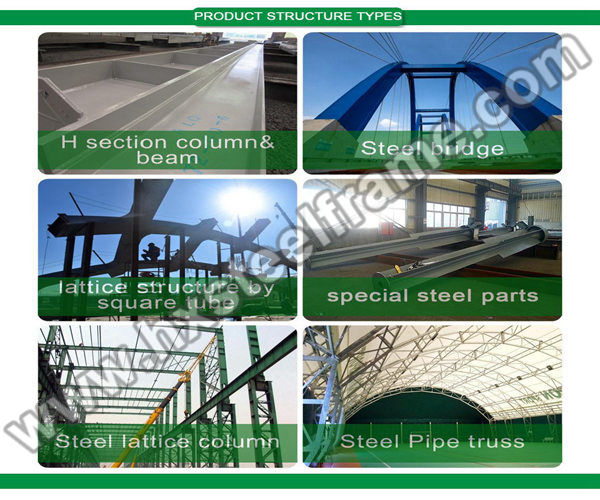

Portal frame is the usual type in the industrial workshop and warehouse shed, other types like lattice structure, space structure, etc also could be designed and manufacturer as per customers request.

2) What is the quality grade of the prefabricated building systems ( made of steel frame ) ?

Q345 is used for main steel structure, Q235 is used for secondary steel structure.

Also we could use international steel as per your demand if order qty is big enough.

3) How about the delivery time for your prefabricated building systems ( made of steel frame ) ?

Usually, within 30-45 days after the order confirmed, also depends on the fabrication quantity.