steel framing material and steel structure fabrication to Kinshasa market

| Min. Order: | 100 Metric Ton |

|---|---|

| Trade Term: | CFR |

| Payment Terms: | L/C |

| Supply Ability: | 9000 Ton/per Month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Binzhou, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 1-58 |

|---|---|

| Means of Transport: | Land |

| Brand Name: | HX |

| Top client Serviced: | SIEMENS, American GE, FRANCE ALSTOM, French energy power, Vale of Brazil |

| Specifications:: | Main Steel: Q345B, Q235B Column&Beam: Welded or Hot rolled H-section Wall&Roof: EPS, Rock wall, PU sandwich, corrugated |

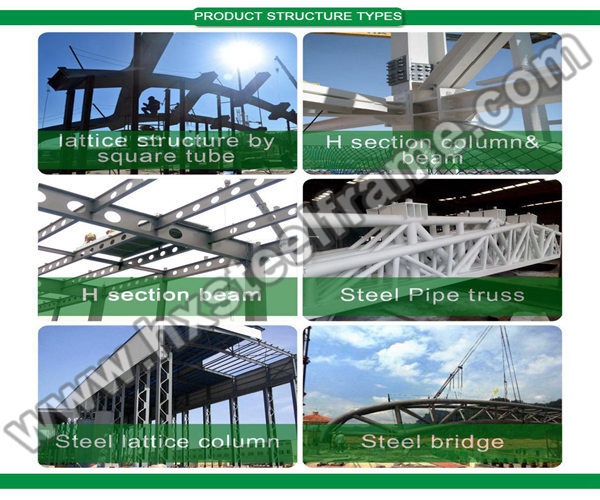

| Main structure: | Welded H section,Lattice structure,Tubular column or beam,space frame etc |

| Service Offered: | Design, fabrication, packing, transport, erection |

| Welding standard: | AWS D1.1 |

| Production Capacity: | 9000 Ton/per Month |

| Packing: | Components will be packaged by steel pallet |

| Delivery Date: | 20 days |

Product Description

1. Why give the production job of Steel building ( made of steel framing material ) to us :

1) CNC punching machine , CNC bending machine , CNC welding machine , plasma cutting , high-power laser cutting and water jet cutting . available to provide multiple cutting service .

2) Well-experienced engineer team and production team for steel structure fabrication , welder working with CWI certificate , according to WPS ( welding procedure specification ) and PQR ( procedure qualification record ) .

3) Professional non-destructive testing , fully equipped .

4) Four painting line can supply high and quickly painting service . Professional surface treatment : hot-dip galvanizing , sandblasting , paint spraying , powder coating , plating .

5) More than 8 years in steel structure experience .

6) Full set of manufacturing process plan to ensure delivery on time .

2. Our company brief :

Our company is the comprehensive enterprise, which gathers the design, processing, production, sale and installation for steel structure. It had passed the certificate of ISO9001:2008 International Quality System and got the Safely Production License. It is located in Shandong province China. The company not only has advanced technique but also has the scientific management system, so the productive force developed rapidly. The company has many production lines for light steel, heavy steel, pipe lines, pressure vessel, steel structure H steel etc. The products adopt high quality raw material from domestic and abroad. The quality and variety of products were in leading position in the same field. It has good prestige. Consequently, our products are selling well in the American, European, Japanese, Asian and the Middle East markets. Due to our quality assurance, competitive prices, and on time delivery, we have developed a large base of repeat customers and got excellent public praise and the best reputation.

3. Project case- Argentina Steel Structure workshop Building:

We are the largest steel structure building materials supplier and manufacturer in Shandong, China.

This steel structure building used for workshop built in 2010 year for our Argentina Customer.

Project Conditions:

1) Size: 5930M2

Main workshop area 80m long* 60m wide* 9m Eaves height( ridge height 10m)

Affiliated workshop area: 1130 square meter.

2) Wall & roof material: V-960 light steel sandwich panel

3) Thermal Insulation: 50mm EPS foam, 12kg/ m3

4) Wind load: 0.79kn/ M2

5) Crane: 8 cranes( lifting capacity: 2 ton)

6) Windows and doors: electrical rolling window&doors, aluminium alloy

4. Our Manufacturing Capability for Steel building ( made of steel framing material ) :

With annual production capacity pf 200, 000 tons, we have established a large steel structure production base which applied advances professional equipment, leading craftwork and technology, and proceeds professionalized, growing-scales steel structure manufacturing. By introducing the world first rate steel structure professional production lines, the company owns advanced professional production equipment for the all automation production line of H type that is most advanced at home, pipe truss structure, box beam production lines etc. Therefore, it can accomplish various processing tasks of light steel, heavy steel, space structure steel component products in high quality and in time. With the gigantic processing and manufacturing demand in the steel structure of project construction, but can also provide steel structure processing service based on the demand of customers.

5. Packaging & Shipping for Steel building ( made of steel framing material ) :

1) Using container:

container of 20 feet, and container of 40 feet

2) By sea for batch goods, for container or bulk-cargo ship, port receiving.

3) Customers specifying freight forwarder or negotiable shipping methods

4) All of the steel column& beams ends and plates will be packed by the blanket to protect them from the crash in the container during the shipment.

5) To make the loading and unloading more efficiently and saving the delivery cost, 40' OT is preferred to loading the steel frames.

6) All the wall and roof panels will be filmed by two sides and fixed stably in the 40HQ container.

7) All the windows and doors will be protected by the bubble rapping papers and fixed stably in the container.

6. FAQ:

1) Q: How could I control the cost of building a Steel building ( made of steel framing material ) ?

A: Firstly, the designing scheme should be mutually discussed and then accepted. Then, the kinds of building materials should be confirmed since different types and qualities make various prices. After that, we will send you a detailed quotation.

2) Q: How Long does it take to build a Steel building ( made of steel framing material ) ?

A: It depends on the size of the warehouse. Generally, the construction period of is 1 month of a 2000-square-meter workshop by a construction team of 8-10 people. It only costs 2-3 weeks to build the steel structure frame.

3) Q: Is it difficult to build a Steel building ( made of steel framing material ) ?

A: totally not, you can let your local teams build it according to the construction drawings and erection guiding video provided by us.