steel building frame made of famous steel structures heavy-duty at Europe area

| Min. Order: | 50 Metric Ton |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 9000 Ton/per Month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Binzhou, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 1-346 |

|---|---|

| Means of Transport: | Land |

| Brand Name: | HX |

| Material Grade: | ASTM A36& A572 JIS SS400 |

| Top client Serviced: | SIEMENS, American GE, FRANCE ALSTOM, French energy power, Vale of Brazil |

| Standard: | ISO standard GB standard Japanese industrial standard |

| Certificates: | 1. ISO9000, ISO14000, ISO18000 by BV France. 2. EN-1090 CE certificate, American CWI, European TWI, European IWE |

| Surface Treatment: | Shot blasting then anti-rust paint or hot dip galvanize |

| Production Capacity: | 9000 Ton/per Month |

| Packing: | Sandwich panels covered with plastic film |

| Delivery Date: | 30 days |

Product Description

1. Technical specs for the steel building frame ( made of steel frame ) :

Item name | Material characteristics | Material Grade | Surface Treatment |

Anchor bolt | Steel rod M24 , M27 | Q235B | |

Steel Column | H shape , Box , steel pipe , Hot rolled sheet | Q235B , Q345B | Paint or Hot dip galvanized |

Steel Beam | H shape , steel Truss , Hot rolled sheet | Q235B , Q345B | Paint or Hot dip galvanized |

Steel Bracing | Steel rod , Steel pipe , Angle steel | Q235B , Q345B | Paint |

Steel Purlin | C or Z shape , steel purlin Thickness :1.8mm ~ 3.0mm | Q235B , Q345B | Hot dip galvanized |

External wall panel , Roof panel | Sandwich panel with EPS , Rock wool , Pu , Glass wool | Steel T = 0.426 ~ 0.8mm , insulation T=50 ~ 150mm | Alu-zinc galvanized then painted |

Door | Sliding or rolling door | Steel or Aluminum sheet , T = 1.0 ~ 1.5mm | Paint or Hot dip galvanized |

Window | alloy-Glass , Aluminium alloy - shutter | T = 1.0 ~ 2.0mm | Alloy |

Day-lighting panel | FRP , T = 1.5mm or T = 1.8mm | Coefficient of thermal expansion : 2.2 x 10 - 5 / cm | Light transmittance 85% |

Ventilator | Turbine ventilator, ventilator along a slope | Steel , stainless steel , PC | Paint , 304 |

Gutter | Galvanized Steel plate , stainless steel plate | T = 2.0mm | Paint , 304 |

Downpipe | PVC pipe , T = 0.5mm | Φ110 , 160 , 200 | |

Bolt | Ordinary , high strength | 10.9S , 4.8s | Bluing for high strength bolts |

2. Our products scope include:

Single layered light and MID-sized workshops and warehouses, steel building frame ( made of steel frame ), single layered heavy duty workshops, wide-span public buildings, high-layered and super high-layered buildings, muti-layered industrial workshops, office buildings and houses, bridges, wide-span highway bridges and bridges in city, viaducts; industrial platform and support; structures that can be dismantled and transported, etc

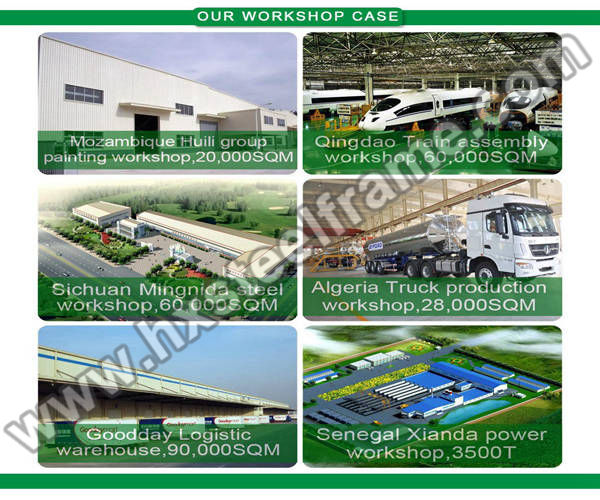

3. Project case- West Chuang Company Steel Structure Workshop / Light steel structure warehouse:

1) Roof: Color-coated Corrugated Steel Sheet with skylight panel

2) Wall: Color-coated Corrugated Steel Sheet

3) Main Steel Framework: Steel Column, Beam, Purlin and other supporting parts with shot blasting and painting process.

4) Material: Q345

5) Window: Plastic Steel Window

6) Door: Sliding Door plus Canopy(all are made by sandwich panel)

7) PVC Downpipe

8) Total 3000tons

4. DESIGN STANDARD& SOFTWARE for steel building frame ( made of steel frame ) :

Standard: America Standard, Australia Standard, England Standard, China Standard, etc.

Software: SAP2000, Auto CAD, PKPM, RSTAB, PROE, MTS, Tekla Structures( Xsteel) , 3D3S, Tarch, etc.

5. Our seaworthy packing system for steel building frame ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) Do you offer service for installation ?

Re: We will give detailed installation drawings and direction info for free. And if you need, we could also send engineers as installation director even a team.

2) What should I provide to build a steel building frame ( made of steel frame ) ?

A: So easy! Design drawing would be a better reference for us. However, you will

never mind if you don't have any. Simply notify us your requirements, such as the

area, wind load, usage of the warehouse etc. Before long, you' ll possess an amazing design.

If you have any new need, please provide your drawing paper or technical parameter for us reference, we will quote for you more precisely and accordingly.

3) Is the steel building frame ( made of steel frame ) erection quick ?

Yes, Steel beam, steel column, crane beams, purlins, support, wall beam, they are prepared in a factory, they are installed only need to connect with bolt on site, this installation is quick and convenient, Only need to provide the installation drawings.