pre engineered metal building components made of heavy steel structure to Lisbon customer

| Min. Order: | 100 Metric Ton |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 8000 Ton/per Month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Binzhou, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 1-597 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | HX |

| Top client Serviced: | SIEMENS, American GE, FRANCE ALSTOM, French energy power, Vale of Brazil |

| Surface Treatment: | Painted by Epoxy paint |

| Service Offered: | Design, fabrication, packing, transport, erection |

| Specifications: | Main Steel: Q345B, Q235B Column&Beam: Welded or Hot rolled H-section Wall&Roof: EPS, Rock wall, PU sandwich, corrugated |

| Installation: | Provide full set of construction drawings and video to direct installation |

| Production Capacity: | 8000 Ton/per Month |

| Packing: | Sandwich panels covered with plastic film |

| Delivery Date: | 20 days |

Product Description

1. pre engineered metal building components ( made of steel frame ) main components description :

1 ) Mainly made by H - section and box girder .

Wide flanges make H - beam have a higher lateral stiffness fit for compression member .

Flanges of H - section with same thickness parallel with one another have strong resistance to bending , easy to composite and joint with other component for your prefab steel structure workshop .

2 ) Support System

Support system of prefab steel structure workshop mainly consist of purlin , cross bracing and angle brace made by Z - section , C - section or angle , allot the payload of column and pillar , transfer the loading to whole frame .

Support system makes the frame structure stand as a unity ; improve the solidity and stabilization of frame itself .

3 ) Roof and wall panel system

Roof and wall panel system mainly made of color steel or color steel sandwich panel .

Roof and wall panel system connected by self-tapping screw , easy and fast to assemble .

Good mechanical property as well as bearing capacity of prefab steel structure workshop .

Multiple color and surface finishing available meet your customization requirement and preference for prefab steel structure workshop .

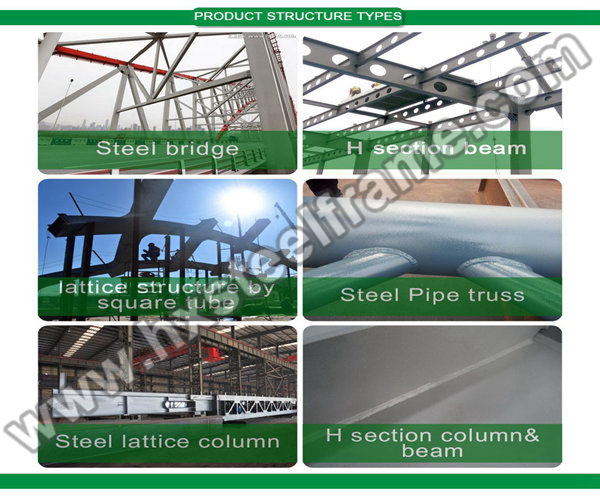

2. Our products scope cover all kinds of steel structure for civil and industrial fields:

As one of the largest structural steel fabricators in China targeting global structural steel market. It takes full advantage of industry-leading technology and advanced equipment, extensive project management skills and high English proficiency, coupled with on-time, on-budget performance, and earns the trusts and supports from the worlds' top clients in a variety of sectors across the globe. As a steel structure solutions leader, we are dedicated to providing professional services for users in various industries, our project covers all kinds of steel structure for civil and industrial fields, like Power Plant [ Incl. HRSG( NPP) & Ducts; ACC; Conveyor] , Oil Gas & Chemicals, Metal & Mining, Commercial Building, steel workshop, high rise building, Theme Park, Modularization and Fireproofing, etc.

With its four well equipped fabrication shops, we have delivered over 300,000 metric tons of fabricated steel structure to the global until now.

3. Internationalized marketing:

Thus far, our steel structure and steel building sell well throughout the world, 90% product exported, exported to more than 40 countries, such as Germany, America, Slovakia, Saudi Arabia, South Africa India, Indonesia, Oman, Bengal, Egypt, Vietnam, Nigeria, Philippines, Namibia, Morocco, Angola, Brazil, Grenada, Sudan, Pakistan, Zambia, Tanzania, Bosnia and Herzegovina, Turkey, Iraq, Kuwait, Myanmar, Singapore, Dubai, Argentina, the United Arab Emirates, Chile, Cameroon, Colombia, Cuba, Algeria, Ethiopia, Equatorial Guinea, Iran, Laos, New Zealand, Panama etc.

The exported weight reaches more than 300,000 tons.

4. Our company' s design and quotation capability for pre engineered metal building components ( made of steel frame ) :

1) We make visual architectural drawings and 3D effect drawings according to customers' demand, enabling customers to see the products they desire clearly. Therefore, the best plan dwgs can be sent to customers efficiently.

2) After deciding the scheme, we will begin to design the building structure. We will carry out stress analysis and structural calculation through " 3D3S " and " PKPM ". Then we conduct secondary optimization of the scheme based on calculation report, and ensure the safety performance of building structure with the most reasonable steel quantity and connection method.

3) After designing the structure, our quotation specialist will make the engineering material bill according to structural design drawings, and provide the final engineering quotation list after referring and adjusting to the material price information on the market.

5. Our seaworthy packing system for pre engineered metal building components ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) Do you provide on-site installation service for pre engineered metal building components ( made of steel frame ) ?

We provides customers with one-stop integrated steel building solution including installation and operation. We have 3 options for on-site installation according to the customer' s specific situation. Firstly, we offer installation instructions and installation video. Secondly, we assign the installation team for the project. Finally, we send professional engineer to guide the local installation team.

2) What' s your delivery time of your pre engineered metal building components ( made of steel frame ) ?

Salesman will confirm the time accordingly, large order should communicate with order management department in advance. Normally, delivery time is 45days after receive deposit. Large order delivery time should be arranged separately.