steel frame factory building and industrial steel construction with ISO

| Min. Order: | 100 Metric Ton |

|---|---|

| Trade Term: | CFR |

| Payment Terms: | L/C |

| Supply Ability: | 9000 Ton/per Month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Binzhou, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 1-856 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | HX |

| Top client Serviced: | SIEMENS, American GE, FRANCE ALSTOM, French energy power, Vale of Brazil |

| Main structure: | Welded H section,Lattice structure,Tubular column or beam,space frame etc |

| Specifications:: | Column&Beam: Welded or Hot rolled H-section Wall&Roof: EPS, Rock wall, PU sandwich, corrugated steel sheet |

| Product Characteristics: | 4)Fire- resistant, clean and health 5)50-year-long life expectancy |

| Quality Control: | The third party, SGS, ASIA INSPECTION all accept |

| Production Capacity: | 9000 Ton/per Month |

| Packing: | Components will be packaged by steel pallet |

| Delivery Date: | 30 days |

Product Description

1. Data of the steel frame factory building ( made of steel frame ) :

Specification | |

Material : | Grade Q235 , equivalent to ASTM A36 Grade Q345 , equivalent to ASTM A572 |

Section : | Any product shape according to customer's requirements |

Certification : | ISO quality system , Chinese GB50221 - 2001 |

Sand Blast : | SA 2.5 Sand blasting |

Welding Technology : | Single level butt welding , fillet welding by electric arc welding , and Gas shielded welding |

Surface treatment : | Hot dip galvanized , Epoxy zinc rich primer Standard : ISO1461 ( 1999 ) , JIS H 8641 - 1999 , ASTM A 123 / A 123M-02 |

Welding Testing | Ultrasonic Testing , X-ray Testing |

Manufacturing Technology | Drilling , Cutting , Assembling , Welding , Rectification , Testing etc |

2. Our value to the client in the steel building fields:

In terms of design, production, shipping, installation,communication, with rich wealth of export experience, we can ensure the safe and timely delivery of the steel structure products directly to the site to meet the construction needs. The rigorous management mechanism guarantees that our team are professional and the products are able to meet demands of customers from various countries.

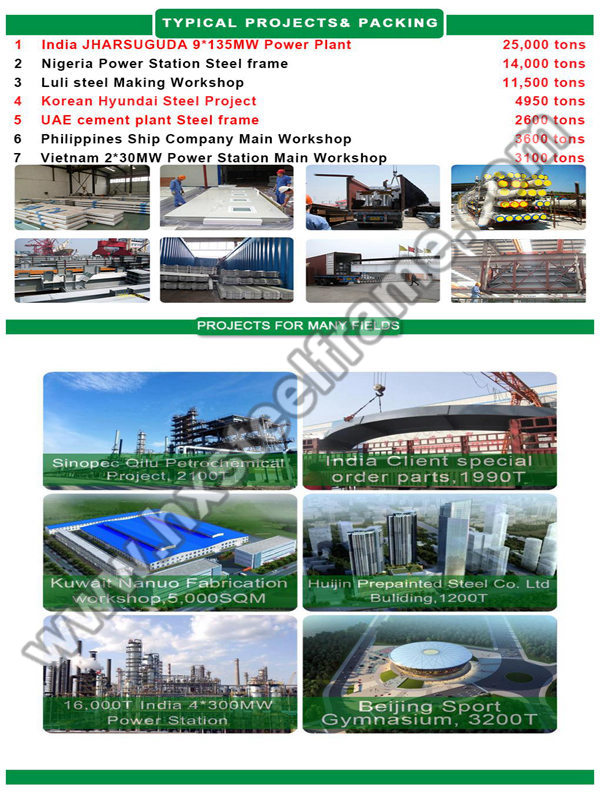

Now we has projects across the country, and also extends business to over 60 countries in Western Europe, Southeast Asia, Africa and South America,such as France, Russia, Brazil, Venezuela, India, Tanzania, Togo, Benin, Namibia, Nigeria, Burkina Faso, Mozambique, Senegal, Angela, Uganda, Rwanda, Guinea, Malawi, Algeria, Zambia, Ethiopia and Mauritania etc. The company is deeply accepted and trusted by clients.

Keep on adopting international standards and industry-leading technology to create architectural masterpieces. We sincerely welcome all of our friends from anywhere to cooperate with our company.

3. Project case- Structural Steel Logistics Warehouse:

This logistics warehouse is constructed for Hidu, it' s located in Qingdao, China, total area is 40, 000m2.

Our company takes 22 days in total to finish the area of 20,000m2, it' s a miracle in this field of steel structure construction, and we got high reputation from our customer.

1) Roof use V760 type 0.6mm steel sheet with 75mm glass wool and attaching veneer.

2) Wall use V840 type 0.6mm steel sheet

3) Skylight panel on roof

4) Ventilator on roof

4. How we ensure the high quality of steel frame factory building ( made of steel frame ) :

After years of exploration, practice and improvement, our company has built an experienced technical team in steel structure. Every project is supposed to go through the following procedures:

1) Owing plasma cutting, flame cutting, available to provide multiple cutting service.

2) Well-experienced engineer team and production team for steel structure fabrication, welder working with CWI certificate, according to WPS( welding procedure specification) and PQR( procedure qualification record) .

3) Professional non-destructive testing, fully equipped.

4) Professional surface treatment: sandblasting, paint spraying, powder coating as per American standard.

5) More than 10 years steel structure fabrication experience

6) Full set of manufacturing process plan to ensure delivery on time.

5. Our seaworthy packing system for steel frame factory building ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) Can I have a visit to your factory before the order ?

A: Why not ? welcome to visit our factory. You can fly to Jinan Airport. We will pick you up in the airport. Hotel booking service is available.

2) Do you supply installation service for steel frame factory building ( made of steel frame ) ?

A: Yes, we do. But you will pay for our professional fee if we install in your local place. Then we will send engineers to supervise it.

3) How long can the steel frame factory building ( made of steel frame ) be used ?

A: The use life of the main structure is the designed used life, that is 50-100 years( standard request of GB) .