prefabricated industrial shed made of metal frame light-gauge provide to Lome

| Min. Order: | 100 Metric Ton |

|---|---|

| Trade Term: | CFR |

| Payment Terms: | L/C |

| Supply Ability: | 3000 Ton/per Week |

| Place of Origin: | Shandong |

Company Profile

| Location: | Binzhou, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 1-851 |

|---|---|

| Means of Transport: | Land |

| Brand Name: | HX |

| Top client Serviced: | SIEMENS, American GE, FRANCE ALSTOM, French energy power, Vale of Brazil |

| Surface Treatment: | Painted by Zinc rich paint Painted by Epoxy paint |

| Drawing Design: | by us dwgs Detailing by us |

| Software used: | American STAAD-Pro Finland Xsteel |

| Service Offered: | Design, fabrication, packing, transport, erection |

| Production Capacity: | 3000 Ton/per Week |

| Packing: | Sandwich panels covered with plastic film |

| Delivery Date: | 15 to 40 days |

Product Description

1. Products description for the prefabricated industrial shed ( made of steel frame ) :

Main Steel | |

Steel Beam Column | Q235B , Q345B |

Secondary Steel | |

Tie Bar | Q235B |

Purlin | C and Z purlin |

Bracing | Q235B |

Accessories | |

Surface | Painted or Hot Dip Galvanized |

Door | Rolling Up Door or Sliding Door |

Window | PVC or Aluminum Alloy |

Roof and Wall Panels | Corrugated Steel Sheet , EPS Sandwich Panel , Rock Wool Sandwich Panel , PU Sandwich Panel |

Others | |

Service | Design , Fabrication and Installation |

We can offer quotations according to customers' drawings and requirements , free design drawings and detailed installation drawings . | |

Design software : Auto CAD , PKPM , MTS , 3D3S , TArch , Tekla Structures ( X steel ) V12.0 , etc | |

Packing | main steel frame with 40 OT roof and panel load in 40 HQ Or According To Customer Requirement |

2. Company In Brief:

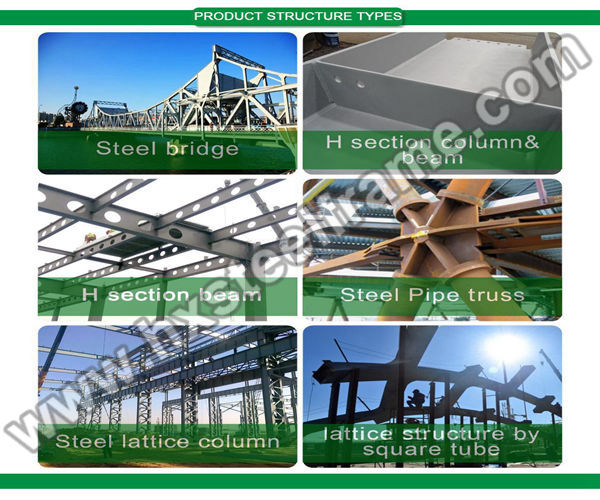

We specializes in providing complete solutions for high-quality steel structure products including: design, fabrication and erection of. Besides pre-engineered buildings, nowadays, we have developed heavy structural industry and commercial projects that aim to provide customers full structures such as workshops, warehouses, plazas, exhibition centers, supermarkets, railway stations, airports and so on …

With a well-trained workforce of over 1, 000 professional staffs, quality management system ISO 9001:2008, ISO 14001: 2004, OHSAS 18001: 2007 and a 200, 000 m2 factory with high technology automatic production facilities, we delivers the optimal solution, high-quality products and perfect services for your project.

Our top serviced client include SIEMENS, GE, India Adani Power, Hyundai Steel etc.

3. Project case- Ningxia prefabricated steel structure workshop, 23000 SQM:

main structure:welding H steel or round steel

knee brace: Angle steel

roof ridge: corrugated steel sheet

Wrapping cover:color steel sheet

roof gutter: color steel sheet

rain spout: PVC pipe

doors: sliding sandwich panel door or metal door

windows: PVC OR ALUMINUM WINDOW

connecting: high strength bolts

characteristic: environment-friendly

lower cost and maintenance easily

4. Our Manufacturing Capability for prefabricated industrial shed ( made of steel frame ) :

With annual production capacity pf 200, 000 tons, we have established a large steel structure production base which applied advances professional equipment, leading craftwork and technology, and proceeds professionalized, growing-scales steel structure manufacturing. By introducing the world first rate steel structure professional production lines, the company owns advanced professional production equipment for the all automation production line of H type that is most advanced at home, pipe truss structure, box beam production lines etc. Therefore, it can accomplish various processing tasks of light steel, heavy steel, space structure steel component products in high quality and in time. With the gigantic processing and manufacturing demand in the steel structure of project construction, but can also provide steel structure processing service based on the demand of customers.

5. Our seaworthy packing system for prefabricated industrial shed ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) How can i get the quotation of the product of prefabricated industrial shed ( made of steel frame ) ?

A:

(1) If you have drawing, we can give you our quotation according to your drawing.

(2) If you have no drawing, my company will make a layout drawing. After you make sure all details in the drawing is no problem, we will send our quotation according to the drawing.

2) Is your price competitive with other companies ?

A: Our business objectives are to give the best price with same quality and best quality with the same price. We will do everything we can to reduce your cost.

3) Do steel constructions harm the nature ?

Answer: Steel is 80% recycling material. So it does less harm to the nature compared with the other type buildings.