light steel structure building and prefab metal buildings CE verified

| Min. Order: | 50 Metric Ton |

|---|---|

| Trade Term: | CFR |

| Payment Terms: | T/T |

| Supply Ability: | 9000 Ton/per Month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Binzhou, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 1-544 |

|---|---|

| Means of Transport: | Land |

| Brand Name: | HX |

| Top client Serviced: | SIEMENS, American GE, FRANCE ALSTOM, French energy power, Vale of Brazil |

| Software used: | AutoCAD, PKPM, MTS, 3D3S, Tarch, Tekla Structures( Xsteel )V12.0.etc |

| Service Offered: | Design, fabrication, packing, transport, erection |

| Shipment by: | bulk ship |

| Quality Control: | The third party, SGS, ASIA INSPECTION all accept |

| Production Capacity: | 9000 Ton/per Month |

| Packing: | Sandwich panels covered with plastic film |

| Delivery Date: | 20 days |

Product Description

1. How to build a light steel structure building ( made of steel frame ) , please check the following table :

Design Data ( important ) | live load on roof ( KN / M2 ) wind speed ( KM / H ) snow load ( KG / M2 ) if have |

Size ( important ) | width length height roof slope |

Type | single slope or double slope muti slope or single span single floor or two floors |

Inter column | 5m , or 6m …. |

Windows & Door | 1 . quantity 2 . size 3 . Location 4 . PVC or aluminum |

Column &Beam | straight cross-section OR Variable cross-section |

Roof & Wall Panel | 1 . Colorful corrugated steel sheet 0.326~0.8mm thick , YX25-210-840 ( 840mm wide ) 3 . sheet+glass fiber(thick 50mm~200mm) |

Purlin | 1 . C purlin 2 . Z purlin |

Accessories | Do you need the skylight belts , Ventilators,down pipe , out gutter etc ? |

Surface Treatment | Shot blasting with anti rust paint or hot dip galvanize |

2. Our Factory:

We were founded and located in Shandong Province, China. We have fixed assets of 180 million RMB and a workshop plant area of more than 200, 000 Square meters. Our manufacturing base covers 360, 000 square meters. In addition, we have more than 960 employees, including 110 intermediate and senior technical staff members. Besides, we have our own installation and construction teams. We also have abundant financial resources and advanced equipment, including H-TYPE and BOX-TYPE steel structure production lines, full-range impeller blasting equipment, production lines of rack and truss, C-TYPE and Z-TYPE steel forming machines, various kinds of machine tools, drilling machines, folding machines and physical and chemical detection equipment.

3. Market covered:

Euro-market: German, England, French, Russia, Georgia

The American market: USA, Canada, Venezuela

Oceania market: Australia, New Zealand, Samoa

The Africa market: Angola, Algeria, Ghana

4. Our engineer team for light steel structure building ( made of steel frame ) :

We owns 36 TEKLA professional designers, by applying computer work station.

They make the model for steel structure items assembling, define the assembly dimension and inspect the connection status of each joint in three-dimensional way through difference perspectives,

which has optimized the design for realizing 100% successful bolt installation, greatly enhancing working efficiency.

We owns 15 professional STAAD-Pro designers.

As for secondary design and partition treatment of drawings, our design team applies STAAD-Pro together with Ram Connection module to optimize joint design to establish scientific and reasonable assembly design scheme.

5. Our seaworthy packing system for light steel structure building ( made of steel frame ) :

We found mature exporting packing and stuffing system:

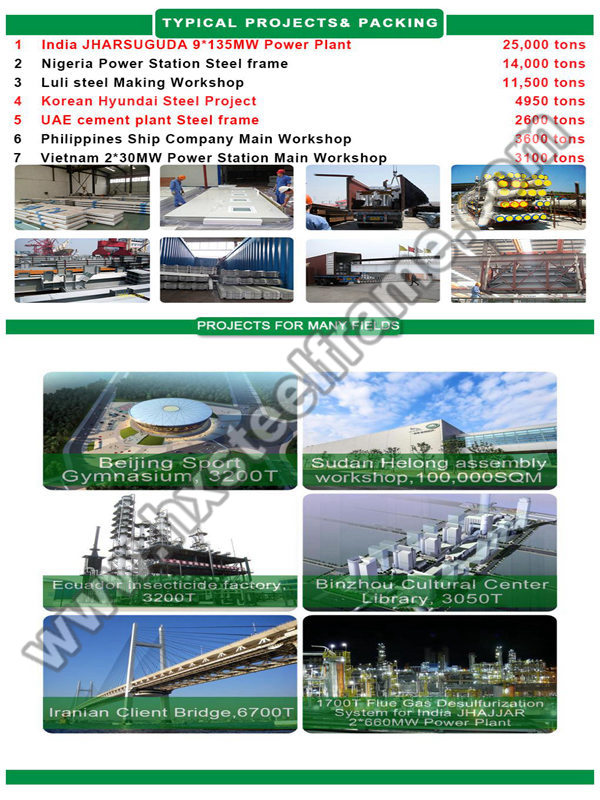

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) What' s included in your service range and what the core value of it is ?

Our service mainly refers to quality products including steel structure, steel building, high rise steel building, light steel structure building ( made of steel frame ), etc, best service on resourcing, inspection, shipment loading, and installation guidance. The core value is " sincere one stop solution for client' s projects and requests" .

2) What's your price level compared with the quality you supplied ?

There are many kinds of quality level in China, which brings about price difference. Offering right quality for our clients' markets and state honestly, our price is reasonable and acceptable for the long term business cooperation.