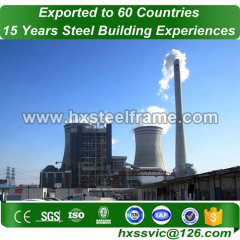

fabrication of steam power plant made of structural steel framing heavy-gauge

| Min. Order: | 120 Metric Ton |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 9000 Ton/per Month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Binzhou, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 1-835 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | HX |

| Top client Serviced: | SIEMENS, American GE, FRANCE ALSTOM, French energy power, Vale of Brazil |

| Main structure: | Welded H section,Lattice structure,Tubular column or beam,space frame etc |

| Specifications:: | Column&Beam: Welded or Hot rolled H-section Wall&Roof: EPS, Rock wall, PU sandwich, corrugated steel sheet |

| Product Characteristics: | High strength, satisfactory property of the steel Anti-seismic, wind resistance, environmental protection |

| Quality Control: | The third party, SGS, ASIA INSPECTION all accept |

| Production Capacity: | 9000 Ton/per Month |

| Packing: | Sandwich panels covered with plastic film |

| Delivery Date: | 30 days |

Product Description

1. fabrication of steam power plant ( made of steel frame ) main components description :

1 ) Mainly made by H - section and box girder .

Wide flanges make H - beam have a higher lateral stiffness fit for compression member .

Flanges of H - section with same thickness parallel with one another have strong resistance to bending , easy to composite and joint with other component for your prefab steel structure workshop .

2 ) Support System

Support system of prefab steel structure workshop mainly consist of purlin , cross bracing and angle brace made by Z - section , C - section or angle , allot the payload of column and pillar , transfer the loading to whole frame .

Support system makes the frame structure stand as a unity ; improve the solidity and stabilization of frame itself .

3 ) Roof and wall panel system

Roof and wall panel system mainly made of color steel or color steel sandwich panel .

Roof and wall panel system connected by self-tapping screw , easy and fast to assemble .

Good mechanical property as well as bearing capacity of prefab steel structure workshop .

Multiple color and surface finishing available meet your customization requirement and preference for prefab steel structure workshop .

2. We are specialized in design and production of prefab steel building, heavy Structure, workshop& warehouse etc. :

We have a strong technical team. We have 960 employees, 80 of them are professional designers and engineers with rich experience in designing and producing. Base in our good management, good quality and excellent after selling service, we got ISO9000, 14000, 18000 by BV France, AWS welder, EN welder, CE certificate, SGS. It brought much business chance to us.

Depending on our professional engineers, most of our products got the design patent. Therefore, our products are not only welcomed by our homeland customers, but also popular among many foreign countries, such as Australia, Qatar, Iran, Sudan, Angola and East-south Asia, Middle East and other regions, etc.

3. Project case- Uganda Steel Coil Processing Plant:

Detailed introduction

Project Description: 30x 120M

Project Type: Gable frame PEB structure with office mezzanine building, Stairs, Platform, etc

Time: Oct. 25, 2012

Location: Uganda

Description:

Site anchor bolt installation all ready finished as planed and all engineering are made as per existing plan to save the client' s investment cost of foundation preparation. We supply the steel structure and panel system within 20 days, which make client very satisfied and we found continuous cooperation with this client after the 1st order.

4. Fabrication Services for fabrication of steam power plant ( made of steel frame ) :

With the annual output of 200, 000 tons. We have 10 fabrication facility lines equipped with CNC cutting, drilling and milling capabilities. We are staffed with skilled CWI, production planning teams, and experienced steel structure building fabricators and painters. Each of our plants has its own unique strengths and assets, which makes us the optimal choice for any type of steel structure building project or heavy / complex steel structure.

5. Our seaworthy packing system for fabrication of steam power plant ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) Would you send engineers to the site to guide for working when installed ?

Re: Yes, Usually we will send two engineers to the site, and the cost shall be in the customer account.

2) Can you design for fabrication of steam power plant ( made of steel frame ) ?

Re: Sure, we have excellent design team, our mainly design software are Auto CAD, PKPM, MTS, 3D3S, Tarch, Tekla Structures( Xsteel) V12.0.etc

3) Are you a factory, Can we visit your factory ?

Re: Yes, We are a professional manufacture of steel structure factory which has better cost advantage than trading company. Welcome you to visit our company.