coal bunker in thermal power plant made of lightweight frames sell well in Russia

| Min. Order: | 100 Metric Ton |

|---|---|

| Trade Term: | CFR |

| Payment Terms: | T/T |

| Supply Ability: | 8000 Ton/per Month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Binzhou, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 1-834 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | HX |

| Top client Serviced: | SIEMENS, American GE, FRANCE ALSTOM, French energy power, Vale of Brazil |

| Design& quote: | We can make design and quotation according to your require or your drawing |

| Main structure: | Welded H section,Lattice structure,Tubular column or beam,space frame etc |

| Specifications:: | Column&Beam: Welded or Hot rolled H-section Wall&Roof: EPS, Rock wall, PU sandwich, corrugated steel sheet |

| Product Characteristics: | High strength, satisfactory property of the steel Anti-seismic, wind resistance, environmental protection |

| Production Capacity: | 8000 Ton/per Month |

| Packing: | Panel accessories will be packaged in wooden box; |

| Delivery Date: | 15 to 40 days |

Product Description

1. Fill the Table below and Sent It to Us, to Get Your Free Proposal for coal bunker in thermal power plant ( made of steel frame ) :

Your location | Country ________ State ________ City _______ Postal code ________ |

Size | Length ________ meter Width ________ meter Height ________ meter |

Storey | Storey number ________ |

Wind Load | ________ km / hour |

Snow Load | ________ kn / m² |

Anti - earthquake | ________ magnitude |

Roof Normal Payload | ________ kg / m² |

Brick wall needed or not | If needed , brick height ________ |

Thermal insulation if needed | If needed , EPS panel , PU sandwich panel Glass wool panel , Rock wool panel are optional . If needed , normal pre-painted steel tile will be used for your project . |

Crane if needed | If needed , _____ units , max lifting weight ____ tons ; max lifting height _____ m |

Storage Cargo condition | If additional requirement for anti-corrosive |

2. About us:

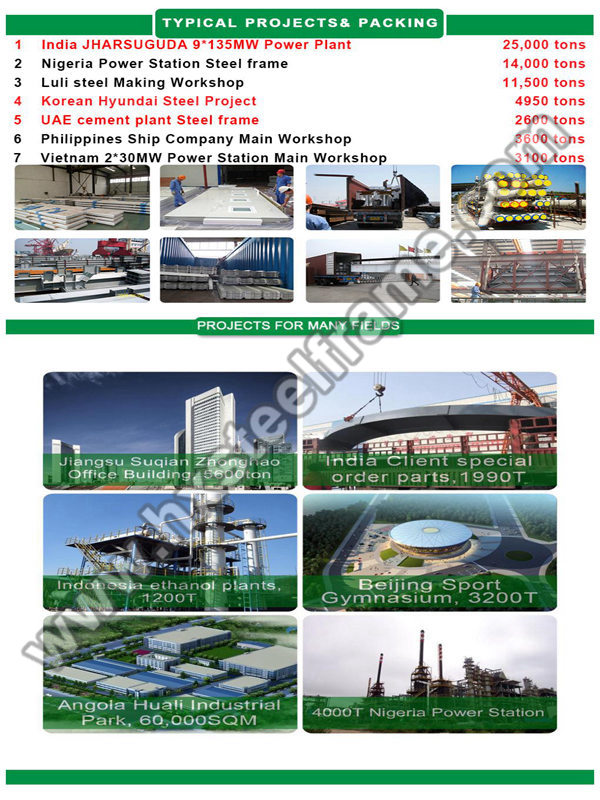

We are a modern steel structure building enterprise specialized in engineering design, manufacture, installation and service of steel structures; and its manufacturing base is situated in Shandong, China. Due to customers' trust and constant innovation of our team, the enterprise is now with a total area of 360, 000 m2 as regards our plants.

We have passed ISO9001: 2000 International Quality System Certification and has a level-one qualification of steel structure project specialized contracting. The enterprise has been verified by BV and SGS which are two global largest verification organizations.

The business scope of us are various steel building, such as steel structure workshop, warehouse, multi-storey building, prefab steel house, container steel house, high-rise frame building and frame structure for large equipment, etc. We also supply various steel structure materials, such as H-type steel, color steel sheet, C-type purlin, Z-type purlin, floor deck as well as steel beam and steel column.

3. Project case- Heavy Structure Steel Welding Fabrication for New Zealand, 5900 tons:

Port: Tianjin

Place Of Origin: China

Brand Name: HX

Model Number: OEM And Design

Application: Industrial Usage

Production: H beam, Purlin, Bracing, Bolts

Price: USD 1200 / Ton

Delivery Time: 86 Days

Price Condition: FOB Tianjin Port

Packaging Details: In Seaworthy Packing

Package Weight: 5900tons

4. Our Manufacturing Capability for coal bunker in thermal power plant ( made of steel frame ) :

With annual production capacity pf 200, 000 tons, we have established a large steel structure production base which applied advances professional equipment, leading craftwork and technology, and proceeds professionalized, growing-scales steel structure manufacturing. By introducing the world first rate steel structure professional production lines, the company owns advanced professional production equipment for the all automation production line of H type that is most advanced at home, pipe truss structure, box beam production lines etc. Therefore, it can accomplish various processing tasks of light steel, heavy steel, space structure steel component products in high quality and in time. With the gigantic processing and manufacturing demand in the steel structure of project construction, but can also provide steel structure processing service based on the demand of customers.

5. Our seaworthy packing system for coal bunker in thermal power plant ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) How do we cooperate on certain project ?

Firstly, please send us your project details and your requirements. Then we will design accordingly, free of charge. Afterwards, please check and confirm whether you like the drawings. If not, we shall get the drawings revised until your confirmation. Finally we make a deal with Trade Assurance.

Project details, Drawings for your project, Revised drawings, Transaction confirmation.

2) What is the delivery time of coal bunker in thermal power plant ( made of steel frame ) ?

Delivery time depends on order quantities. Generally, the delivery time will be 1-2 months after receiving deposit.

3) What' s your Payment term for the coal bunker in thermal power plant ( made of steel frame ) ?

40% advance payment by T/ T, the balance before delivery.