thermal power plant structure and steel industrial buildings hot-galvanized

| Min. Order: | 100 Metric Ton |

|---|---|

| Trade Term: | CFR |

| Payment Terms: | T/T |

| Supply Ability: | 9000 Ton/per Month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Binzhou, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 1-830 |

|---|---|

| Means of Transport: | Land |

| Brand Name: | HX |

| Top client Serviced: | SIEMENS, American GE, FRANCE ALSTOM, French energy power, Vale of Brazil |

| Software used: | American SAP2000 American STAAD-Pro |

| Service Offered: | Design, fabrication, packing, transport, erection |

| Shipment by: | Container bulk ship |

| Welding standard: | AWS D1.1 |

| Production Capacity: | 9000 Ton/per Month |

| Packing: | Components will be packaged by steel pallet |

| Delivery Date: | 30 days |

Product Description

1. Products description for the thermal power plant structure ( made of steel frame ) :

Main Steel | |

Steel Beam Column | Q235B , Q345B |

Secondary Steel | |

Tie Bar | Q235B |

Purlin | C and Z purlin |

Bracing | Q235B |

Accessories | |

Surface | Painted or Hot Dip Galvanized |

Door | Rolling Up Door or Sliding Door |

Window | PVC or Aluminum Alloy |

Roof and Wall Panels | Corrugated Steel Sheet , EPS Sandwich Panel , Rock Wool Sandwich Panel , PU Sandwich Panel |

Others | |

Service | Design , Fabrication and Installation |

We can offer quotations according to customers' drawings and requirements , free design drawings and detailed installation drawings . | |

Design software : Auto CAD , PKPM , MTS , 3D3S , TArch , Tekla Structures ( X steel ) V12.0 , etc | |

Packing | main steel frame with 40 OT roof and panel load in 40 HQ Or According To Customer Requirement |

2. Why Our thermal power plant structure ( made of steel frame ) is your Right Choice:

1) Stable and deep financial capacity

Any investment is an important decision and should be realized through a financially stable company. Our deep community roots and stout economic strength gives us an exceptional advantage in hiring experienced professionals who will complete your project to your expectations.

2) Competitive Prices

Our production capacity(approximately 200,000 metric tons annually) together with effective and economic engineering and manufacturing methods enable us to offer the most competitive prices in the industry.

3) Fast Quotations

Quotations for simple buildings can be submitted quickly due to vast experience of our staff and the advanced design software we use.

4) Fast Delivery

We are able to design, detail, fabricate and supply simple steel buildings in approximately 4 weeks. Most of our buildings are delivered and erected within 8 weeks(this relies on various factors such as site position, weather etc).

5) Site Supervision

A site supervisor is always present at site to ensure that work is being carried out satisfactorily. Any problems that arise are quickly dealt with to minimize any delays. Safety on site is also made a priority.

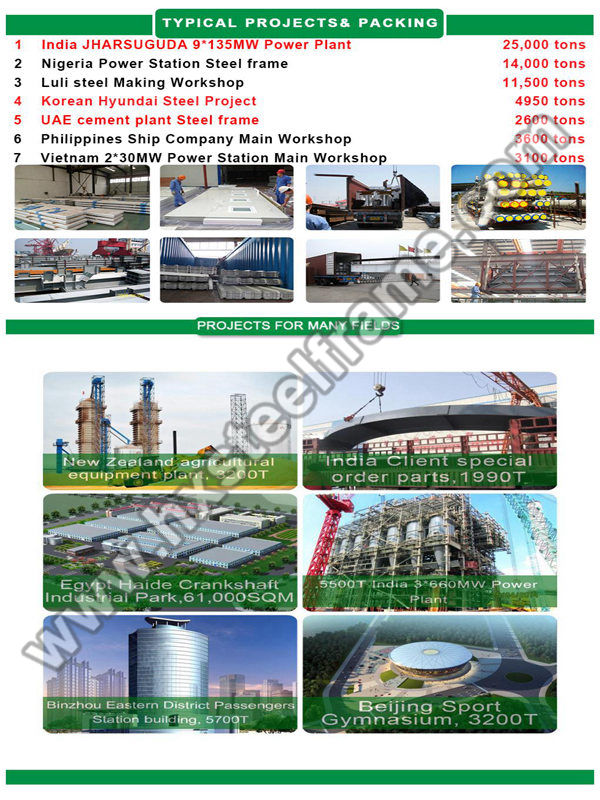

3. Project case- AIRCRAFT HANGAR IN IRAN( 2013) :

The aircraft hangar in IRAN takes up 69M* 32M square meters with partial second floor. The eave height is 7.5meter, span is 32 meter. Drainage slope is 5% .

Main steel structure: welded H steel;

Purlin: cold-rolled C section steel;

Cladding: color steel sheet with foil insulation on roof and glass wool sandwich panels.

4. Fabrication Services for thermal power plant structure ( made of steel frame ) :

With the annual output of 200, 000 tons. We have 10 fabrication facility lines equipped with CNC cutting, drilling and milling capabilities. We are staffed with skilled CWI, production planning teams, and experienced steel structure building fabricators and painters. Each of our plants has its own unique strengths and assets, which makes us the optimal choice for any type of steel structure building project or heavy / complex steel structure.

5. Our seaworthy packing system for thermal power plant structure ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) How about the delivery time of the thermal power plant structure ( made of steel frame ) ?

Reply: Usually, 5000SQM or 800tons steel building within 45-60 days after the order confirmed, also depends on the fabrication quantity.

2) What makes you different from other manufacturers ?

We believe our service department has the experience and knowledge to safely service your need for structural steel construction, such as industrial workshop, light steel warehouse, container house, thermal power plant structure ( made of steel frame ). We have trained service technicians who will be able to help your erection, and have been providing our customer's an effective service solution.

3) Can I customize my thermal power plant structure ( made of steel frame ) ?

Answer: We have as a wide variety of finishes and features that will satisfy your personal taste and needs. Please contact our sales to explain some detail you want to customize the warehouse.