workshop steel buildings and steel warehouse construction recyclable nice made

| Min. Order: | 100 Metric Ton |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C |

| Supply Ability: | 3000 Ton/per Week |

| Place of Origin: | Shandong |

Company Profile

| Location: | Binzhou, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 1-824 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | HX |

| Top client Serviced: | SIEMENS, American GE, FRANCE ALSTOM, French energy power, Vale of Brazil |

| Specifications:: | Wall&Roof: EPS, Rock wall, PU sandwich, corrugated steel sheet |

| Product Characteristics: | 1)Fine gloss exterior, anti-corrosive 2)High strength, satisfactory property of the steel |

| Quality Control: | The third party, SGS, ASIA INSPECTION all accept |

| Installation: | Engineer are able to stay at site to direct construction. |

| Production Capacity: | 3000 Ton/per Week |

| Packing: | Panel accessories will be packaged in wooden box; |

| Delivery Date: | 15 to 40 days |

Product Description

1. Technical specs for the workshop steel buildings ( made of steel frame ) :

Item name | Material characteristics | Material Grade | Surface Treatment |

Anchor bolt | Steel rod M24 , M27 | Q235B | |

Steel Column | H shape , Box , steel pipe , Hot rolled sheet | Q235B , Q345B | Paint or Hot dip galvanized |

H shape , steel Truss , Hot rolled sheet | Q235B , Q345B | Paint or Hot dip galvanized | |

Steel Bracing | Steel rod , Steel pipe , Angle steel | Q235B , Q345B | Paint |

Steel Purlin | C or Z shape , steel purlin Thickness :1.8mm ~ 3.0mm | Q235B , Q345B | Hot dip galvanized |

External wall panel , Roof panel | Sandwich panel with EPS , Rock wool , Pu , Glass wool | Steel T = 0.426 ~ 0.8mm , insulation T=50 ~ 150mm | Alu-zinc galvanized then painted |

Door | Sliding or rolling door | Steel or Aluminum sheet , T = 1.0 ~ 1.5mm | Paint or Hot dip galvanized |

Window | alloy-Glass , Aluminium alloy - shutter | T = 1.0 ~ 2.0mm | Alloy |

Day-lighting panel | FRP , T = 1.5mm or T = 1.8mm | Coefficient of thermal expansion : 2.2 x 10 - 5 / cm | Light transmittance 85% |

Ventilator | Turbine ventilator, ventilator along a slope | Steel , stainless steel , PC | Paint , 304 |

Gutter | Galvanized Steel plate , stainless steel plate | T = 2.0mm | Paint , 304 |

Downpipe | PVC pipe , T = 0.5mm | Φ110 , 160 , 200 | |

Bolt | Ordinary , high strength | 10.9S , 4.8s | Bluing for high strength bolts |

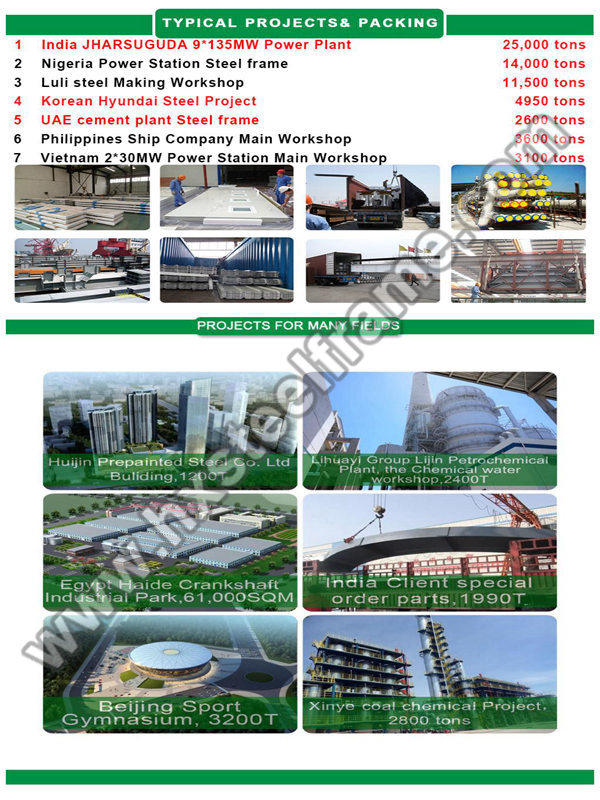

2. Our Company Brief:

We are a professional manufacture who' s devoted to steel structure building construction. We provide the whole set of services include making construction design, producing products and installation.

We are located in Shandong Province. Our factory workshop covering an area of 200,000 square meters. We have 960 workers,including 50 high quality engineering technical personnel. We could produce up to 15,000 tons of steel structure each month. Including H section, lattice steel structure, tubular structure, space frame etc.

We are always stick to the tenent that "quality first,customer first" . When you choose us, you will have peace of mind for many years to come. We are here in Shandong province, China. We are looking forward to your coming!

3. Project case- Russia Office Building, workshop and warehouse Project, 2012:

Detailed introduction

Project Scale: 3-floor heavy office building, 10ton crane in workshop and warehouse, total 3 buildings, tonnage 1240ton

Project scope: Construction drawings design, shop-drawing design, material procurement, steel structure fabrication and painting, and floor deck

4. Fabrication Services for workshop steel buildings ( made of steel frame ) :

With the annual output of 200, 000 tons. We have 10 fabrication facility lines equipped with CNC cutting, drilling and milling capabilities. We are staffed with skilled CWI, production planning teams, and experienced steel structure building fabricators and painters. Each of our plants has its own unique strengths and assets, which makes us the optimal choice for any type of steel structure building project or heavy / complex steel structure.

5. Our seaworthy packing system for workshop steel buildings ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) How can I install these workshop steel buildings ( made of steel frame ) together as a building after cargo arrived ?

Normally, most clients choose to install the steel building structure frame themselves or ask local technical engineer for further instruction.

If local technical support is not available or cost too much, we could also provide technical support engineer cross over-seas for installation guide even with our installation engineering team.

2) How to maintain my workshop steel buildings ( made of steel frame ) years of using ?

workshop steel buildings ( made of steel frame ) are built for long-time, reliable, steady usage purpose, the maintenance process is easy to operate and complete, most our product can live 10-15 years with minimal maintenance work like gel filled and paint spray. We will keep tracking the usage performance of our products and provide maintenance instruction for our clients.