space frame roof structure building by metal structure frame for importer in Belmopan

| Min. Order: | 100 Metric Ton |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 3000 Ton/per Week |

| Place of Origin: | Shandong |

Company Profile

| Location: | Binzhou, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 1-1021 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | HX |

| Top client Serviced: | SIEMENS, American GE, FRANCE ALSTOM, French energy power, Vale of Brazil |

| Certificates: | EN-1090 CE certificate, American CWI, European TWI, European IWE |

| Material Grade: | Chinese Q235& Q345B |

| Surface Treatment: | painted with PPG |

| Drawing Design: | by client or by us |

| Production Capacity: | 3000 Ton/per Week |

| Packing: | Components will be packaged by steel pallet |

| Delivery Date: | usually as customers'order |

Product Description

1. Design data of the space frame roof structure building ( made of steel frame ) that we need for price evaluation:

We can design the project in 3 days , kindly inform us all the necessary data and information to help us offer the best price and service for you. Such as : | |

Size | Length , width , height , eave height , roof pitch , etc |

Design load | Max wind speed ( KM / H ) , Max snow load ( KG / M2 ) Earthquake |

Roof and Wall material | We can supply single corrugated color steel sheet and EPS sandwich steel panel |

Windows and gates | Size quantity and location |

Surface treatment | Paint or hot dip galvanized |

Any other requirements | |

We believe our best quality steel structure , excellent service and good credibility are worth your trust . If you have needs , please contact us for more information! Looking forward to cooperating with you ! | |

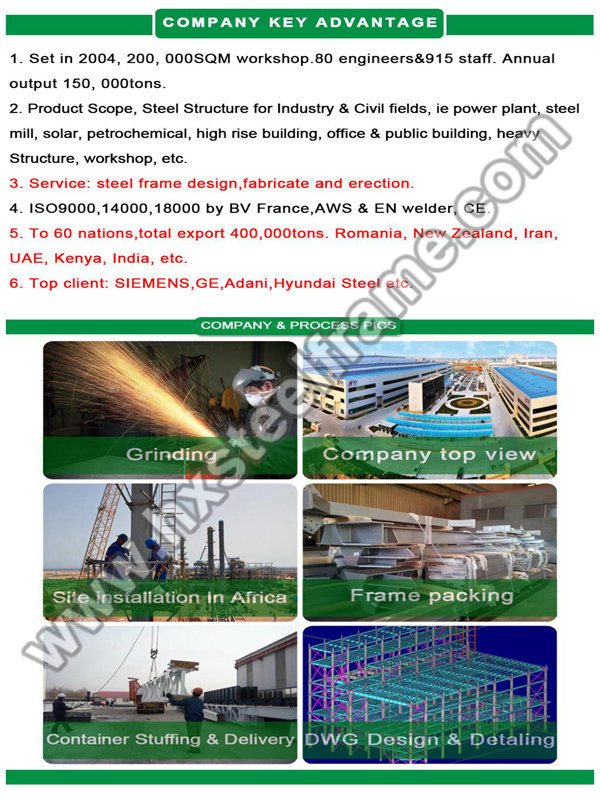

2. Our company brief :

Our company is the comprehensive enterprise, which gathers the design, processing, production, sale and installation for steel structure. It had passed the certificate of ISO9001:2008 International Quality System and got the Safely Production License. It is located in Shandong province China. The company not only has advanced technique but also has the scientific management system, so the productive force developed rapidly. The company has many production lines for light steel, heavy steel, pipe lines, pressure vessel, steel structure H steel etc. The products adopt high quality raw material from domestic and abroad. The quality and variety of products were in leading position in the same field. It has good prestige. Consequently, our products are selling well in the American, European, Japanese, Asian and the Middle East markets. Due to our quality assurance, competitive prices, and on time delivery, we have developed a large base of repeat customers and got excellent public praise and the best reputation.

3. Project case- Qilu Petro-chemical Heavy Steel Workshop:

Size: 55000 square meter workshop, Single Span 39m, eave height 18m, mainly loading bear steel member over 100Ton, totally quantity of steel 6000Ton.

Steel Column: Q345B Four tube lattice column. Painted: 120um epoxy zinc painted.

Roof Structure: Q235B Pipe Truss Structure. Painted: 120um epoxy zinc painted.

Crane Beam: Q345B H section Steel Beam. Painted: 120um epoxy zinc painted.

Secondary Structure

Roof Horizontal Bracing: Q235B Angle Steel, Painted: three layer white color anti-rust Alkyd painted

Wall X Cross Bracing: Q235B Double Angle Steel, Painted: three layer white color anti-rust Alkyd painted

Tie Beam: Q235B Welding Pipe, Painted: three layer white color anti-rust Alkyd painted.

Roof Purlin: Galvanized C section steel

Wall Purlin: Galvanized C section steel

Steel Rod: Galvanized Steel Rod.

Panel system

Roof: 0.5mm Single Color sheet

Wall: 0.5mm Single Color sheet

4. We found international surface treatment system for the space frame roof structure building ( made of steel frame ) :

We got NACE 1 and 2 level certificate as per American standard.

We build professional enclosed shot blasting workshop, enclosed sand blasting room, 34000m2 fully-enclosed painting workshop and 20, 000 m2 enclosed packing workshop.

5. Packaging & Shipping for space frame roof structure building ( made of steel frame ) :

1) Steel structure components will be packaged by steel pallet made by channel steel, and the end plate will be properly protected.

2) Sandwich panels will be covered with plastic film.

3) Bolts and accessories will be loaded into wooden boxes.

4) Each column & beam will be marked according to installation drawing.

6. FAQ:

1) How about the derust grade of your space frame roof structure building ( made of steel frame ) ?

Reply: Ball blasting Sa2.5 on main steel structure or by Galvanized frame;

manual derust St2.5 on secondary steel structure.

2) What kind of panel used for the roof and wall ?

Reply: Color corrugated steel sheet and sandwich panel could be used. Sandwich panel performs well on the heat insulation, sound insulation. Common sandwich materials are EPS, glass wool and PU sandwich panels.

3) Are space frame roof structure building ( made of steel frame ) expensive ?

Answer: The steel structure of our company is economic. Its technology and materials used decreases waste expenses such as wood, decorative stone, brick etc. All the material including the steel frames, wall body and roof for installation are prefabricated during the production process, therefore the labor costs for installation is decreased.