building steel buildings and steel building kits long life at Quito area

| Min. Order: | 100 Metric Ton |

|---|---|

| Trade Term: | CFR |

| Payment Terms: | T/T |

| Supply Ability: | 9000 Ton/per Month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Binzhou, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 1-493 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | HX |

| Top client Serviced: | SIEMENS, American GE, FRANCE ALSTOM, French energy power, Vale of Brazil |

| Surface Treatment: | Painted or HDG or As Customer demand painted with PPG painted with international paint |

| Software used: | American SAP2000 American STAAD-Pro Finland Xsteel |

| Shipment by: | Container or bulk ship |

| Welding standard: | AWS D1.1 |

| Production Capacity: | 9000 Ton/per Month |

| Packing: | Panel accessories will be packaged in wooden box |

| Delivery Date: | 15 to 40 days |

Product Description

1. Design data of the building steel buildings ( made of steel frame ) that we need for price evaluation:

We can design the project in 3 days , kindly inform us all the necessary data and information to help us offer the best price and service for you. Such as : | |

Size | Length , width , height , eave height , roof pitch , etc |

Design load | Max wind speed ( KM / H ) , Max snow load ( KG / M2 ) Earthquake |

Roof and Wall material | We can supply single corrugated color steel sheet and EPS sandwich steel panel |

Windows and gates | Size quantity and location |

Surface treatment | Paint or hot dip galvanized |

Any other requirements | |

We believe our best quality steel structure , excellent service and good credibility are worth your trust . If you have needs , please contact us for more information! Looking forward to cooperating with you ! | |

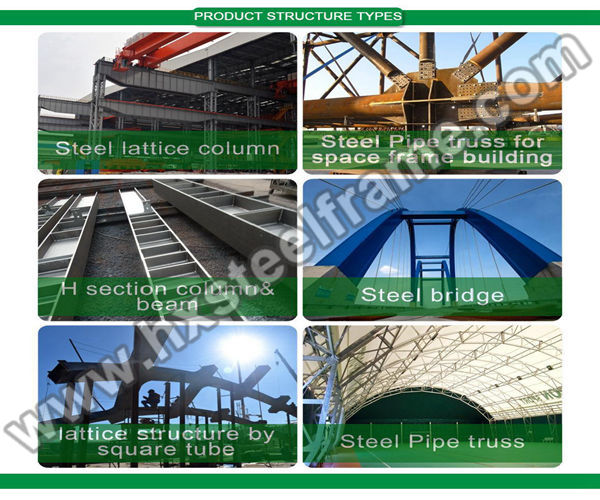

2. We supply both common steel building and the special steel structure:

Besides structural steel building like workshop, warehouse, high rise building, building steel buildings ( made of steel frame ) etc, we can also do nonstandard structural steel member fabrication according to client' s sample or drawings, like special shape structures, board girder, industrial steel frames, belt conveyor and other supporting frames, steel gallery, reclaimer and deck parts etc.

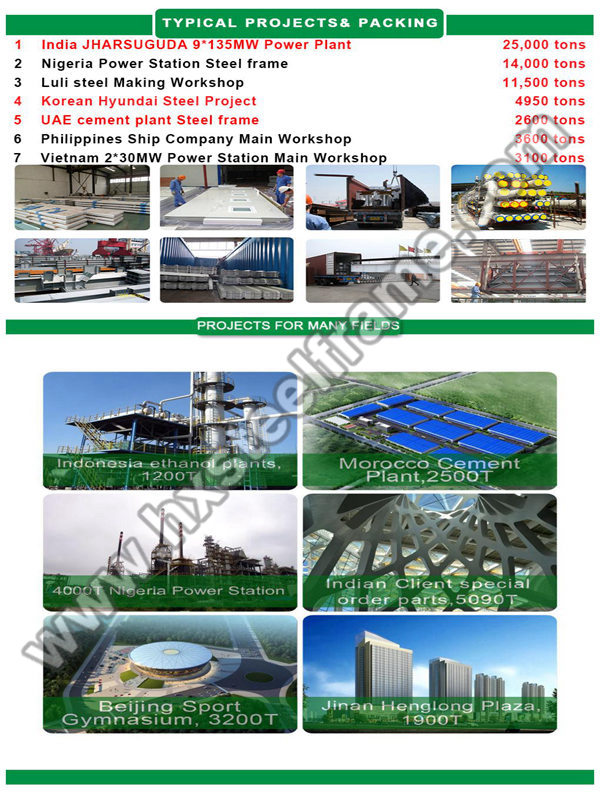

3. Project case- Singapore Ship Manufacturing Yard, 1100ton:

Detailed introduction

Location: Singapore

Tonnage: 1100ton

Structure Type: 40m x150m, lattice column and truss girder with 30MT crane capacity.

Function: Ship Manufacturing/ Repair Yard

Execution: Feb 2011~ April, 2013

This client pay much attention on the product surface quality, after they check our welding like quality and the smooth surface after painting, they made the decision to work with us without any hesitation.

Our good surface quality is due to we found international surface treatment regulation for many years.

We got NACE 1 and 2 level certificate as per American standard. We build professional enclosed shot blasting workshop, enclosed sand blasting room, 34000M2 fully-enclosed painting workshop and 20,000 SQM enclosed packing workshop.

4. DESIGN STANDARD& SOFTWARE for building steel buildings ( made of steel frame ) :

Standard: America Standard, Australia Standard, England Standard, China Standard, etc.

Software: SAP2000, Auto CAD, PKPM, RSTAB, PROE, MTS, Tekla Structures( Xsteel) , 3D3S, Tarch, etc.

5. Our seaworthy packing system for building steel buildings ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) How can I install these building steel buildings ( made of steel frame ) together as a building after cargo arrived ?

Normally, most clients choose to install the steel building structure frame themselves or ask local technical engineer for further instruction.

If local technical support is not available or cost too much, we could also provide technical support engineer cross over-seas for installation guide even with our installation engineering team.

2) How to maintain my building steel buildings ( made of steel frame ) years of using ?

building steel buildings ( made of steel frame ) are built for long-time, reliable, steady usage purpose, the maintenance process is easy to operate and complete, most our product can live 10-15 years with minimal maintenance work like gel filled and paint spray. We will keep tracking the usage performance of our products and provide maintenance instruction for our clients.