steel building beams and metal building structure with CE installed in Managua

| Min. Order: | 150 Metric Ton |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C |

| Supply Ability: | 8000 Ton/per Month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Binzhou, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 1-639 |

|---|---|

| Means of Transport: | Land |

| Brand Name: | HX |

| Software used: | PKPM Tekla |

| Service Offered: | Design, fabrication, packing, transport, erection |

| Top client Serviced: | SIEMENS, American GE, FRANCE ALSTOM, French energy power, Vale of Brazil |

| Specifications:: | Main Steel: Q345B, Q235B Column&Beam: Welded or Hot rolled H-section Wall&Roof: EPS, Rock wall, PU sandwich, corrugated |

| Main structure: | Welded H section,Lattice structure,Tubular column or beam,space frame etc |

| Production Capacity: | 8000 Ton/per Month |

| Packing: | Components will be packaged by steel pallet |

| Delivery Date: | 15 to 40 days |

Product Description

1. Why give the production job of steel building beams ( made of steel frame ) to us :

1) CNC punching machine , CNC bending machine , CNC welding machine , plasma cutting , high-power laser cutting and water jet cutting . available to provide multiple cutting service .

2) Well-experienced engineer team and production team for steel structure fabrication , welder working with CWI certificate , according to WPS ( welding procedure specification ) and PQR ( procedure qualification record ) .

3) Professional non-destructive testing , fully equipped .

4) Four painting line can supply high and quickly painting service . Professional surface treatment : hot-dip galvanizing , sandblasting , paint spraying , powder coating , plating .

5) More than 8 years in steel structure experience .

6) Full set of manufacturing process plan to ensure delivery on time .

2. About us:

Our company commenced its operations in 2004, and pioneered the high-end metal building products market in China. We have been the first mover in China, right from workshop, high rise building, steel building beams ( made of steel frame ) etc to all kinds of pre-engineered buildings.

Today, we are a leading turnkey Pre-Engineered Steel building Construction Solution provider in China with integrated facilities for design, manufacture, logistics, supply and project execution capabilities for pre-engineered steel buildings. We holds a significant part of market share in Asia for metal building systems. We works in close association with industry leaders in project development and construction, providing support to critical industrial, commercial and infrastructure projects.

We are also a certified green building partner and all our products comply with international green norms.

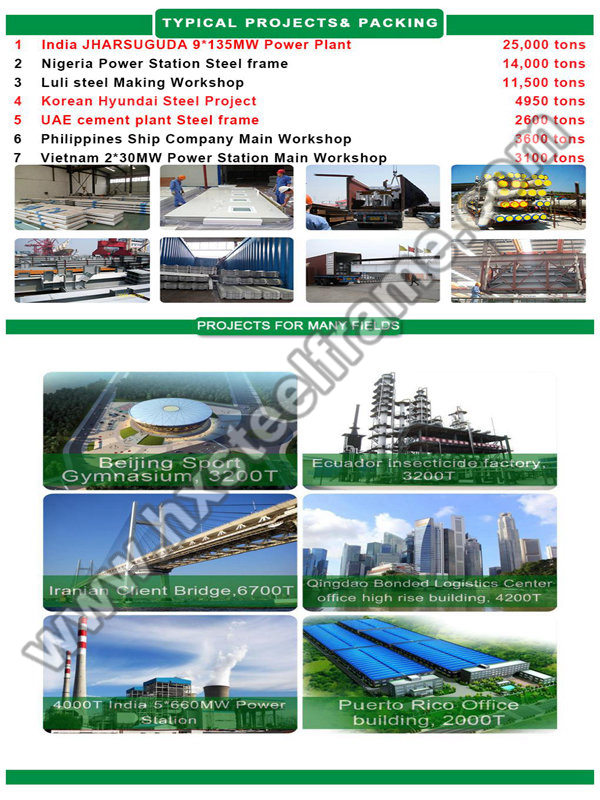

3. Some of OUR WORKSHOP/ WAREHOUSE PROJECTS:

1) AREVA Transformer Factory Project:

Covering an area totaled 33, 842 sq.m, the program consumed steel in 4299 tons, the column height is 31-33 m, and the inside is installed with the bunk bed traveling crane with the maximum hoisting capacity in 400 tons.

2) NEW ZEALAND Barns / Grain Warehouses:

light gauge steel structure with cold bended profiles.

3) BOLIVIA Cement Plant:

Steel consumption: 3, 655 tons in the first phase, 7200 tons in the second phase.

4) LDK Polysilicon Public Project:

Was generally contracted by FLR CO., LTD, the total steel consumption volume for Phase I project reached over 3000 tons and this program was in a high-rise steel structure of 4-7 floors.

4. The services that we can provide for steel building beams ( made of steel frame ) :

1) We have our own technical teams, so we can design, fabricate and install all kinds of steel structure building according to customers requirement.

2) It's very easy to install the steel structure building in your side according to our installation drawings. Also, we will supply all technical support during installation and after-sale service.

5. Our seaworthy packing system for steel building beams ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) How can I install these steel building beams ( made of steel frame ) together as a building after cargo arrived ?

Normally, most clients choose to install the steel building structure frame themselves or ask local technical engineer for further instruction.

If local technical support is not available or cost too much, we could also provide technical support engineer cross over-seas for installation guide even with our installation engineering team.

2) How to maintain my steel building beams ( made of steel frame ) years of using ?

steel building beams ( made of steel frame ) are built for long-time, reliable, steady usage purpose, the maintenance process is easy to operate and complete, most our product can live 10-15 years with minimal maintenance work like gel filled and paint spray. We will keep tracking the usage performance of our products and provide maintenance instruction for our clients.