welding structural steel for metal retail building construction sale to Paris

| Min. Order: | 50 Metric Ton |

|---|---|

| Trade Term: | CFR |

| Payment Terms: | L/C |

| Supply Ability: | 10000 Ton/per Month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Binzhou, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 1-278 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | HX |

| Top client Serviced: | SIEMENS, American GE, FRANCE ALSTOM, French energy power, Vale of Brazil |

| Material Grade: | ASTM A36& A992 |

| Certificates: | 1. ISO9000, ISO14000, ISO18000 by BV France. 2. EN-1090 CE certificate, American CWI, European TWI, European IWE |

| Welding standard: | AWS D1.1 |

| Design& quote: | We can make design and quotation according to your require or your drawing |

| Production Capacity: | 10000 Ton/per Month |

| Packing: | Bolts and accessories loaded into wooden box |

| Delivery Date: | 30 days |

Product Description

1. Why give the production job of Steel building ( made of welding structural steel ) to us :

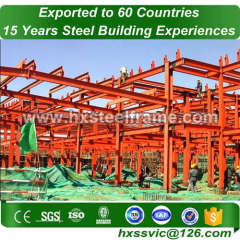

1) CNC punching machine , CNC bending machine , CNC welding machine , plasma cutting , high-power laser cutting and water jet cutting . available to provide multiple cutting service .

2) Well-experienced engineer team and production team for steel structure fabrication , welder working with CWI certificate , according to WPS ( welding procedure specification ) and PQR ( procedure qualification record ) .

3) Professional non-destructive testing , fully equipped .

4) Four painting line can supply high and quickly painting service . Professional surface treatment : hot-dip galvanizing , sandblasting , paint spraying , powder coating , plating .

5) More than 8 years in steel structure experience .

6) Full set of manufacturing process plan to ensure delivery on time .

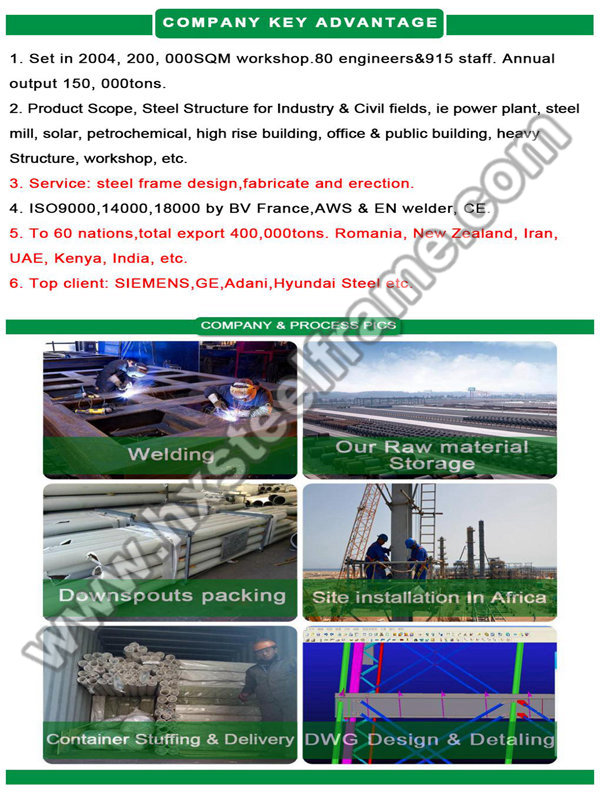

2. Company Advantages:

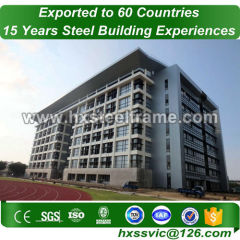

Our Corporation is able to offer complete services for pre-engineered buildings and steel structure projects including: design, fabrication, erection and after-sales services. This integrated production process will bring to our customers huge advantages of an optimal solution, high-quality products and perfect services.

WHAT MAKES US DIFFERENT ?

1) Competitive price

The advanced self-contained high automatic design production line along with experienced and professional staffs help us to bring out the most competitive price.

2) Quality assurance

We produces all structural components of pre-engineered buildings, steel structure projects at the factory with ISO 9001: 2008 quality control system. we have a Quality Control Department who guarantees our products to meet international standards.

3) Fast delivery

With 200, 000 m2 of manufacturing factory and a professional highly trained erection team who is strictly supervised by project management board, we are committed to manufacturing and provide products on schedule.

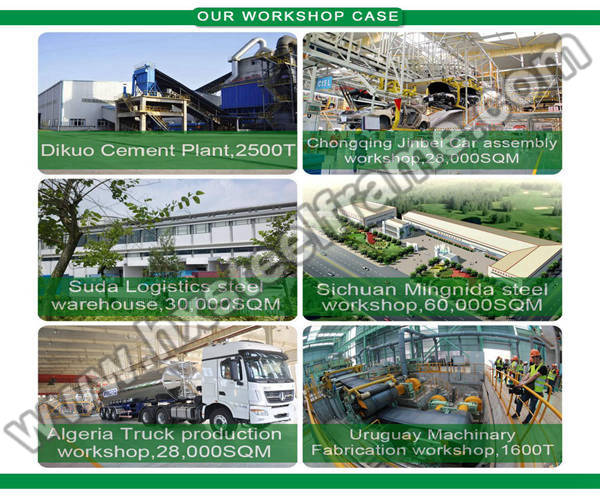

3. Project case- West Chuang Company Steel Structure Workshop / Light steel structure warehouse:

1) Roof: Color-coated Corrugated Steel Sheet with skylight panel

2) Wall: Color-coated Corrugated Steel Sheet

3) Main Steel Framework: Steel Column, Beam, Purlin and other supporting parts with shot blasting and painting process.

4) Material: Q345

5) Window: Plastic Steel Window

6) Door: Sliding Door plus Canopy(all are made by sandwich panel)

7) PVC Downpipe

8) Total 3000tons

4. Our Software for design and detailing of Steel building ( made of welding structural steel ) :

We are located in Shandong China, in response to the increasing demand for Qualified Steel structure and steel building Products on industry, commercial and residential construction.

Utilizing state of the art computer software( Staad pro V8I, PKPM, SAP2000, MIDAS, RAM Connection Standalone 10) for the designs and detailing. We provide you the most competitive design and the highest quality shop drawings, ensuring clear representation of your project requirement that enables faster and economic construction on site.

5. Our seaworthy packing system for Steel building ( made of welding structural steel ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) I just need a small Steel building ( made of welding structural steel ), do you accept small order ?

It' s no problem, we would like to grow up with you together.

2) I am a designer; Can you help me to produce the steel structure which we designed ?

Our mission is to help customers to be successful. So it' s welcome if we can help you solve problem and make your design come true.

3) Can you offer Door to Door service ? Because i do not know how to do customs clearance.

Yes. We can make Door to Door service to help you save much time of shipping. Also we have big discount with shipping company because we have do much of this every day. So it will save your time also money.