advantage steel building made of built-up H beam recyclable installed in Egypt

| Min. Order: | 100 Metric Ton |

|---|---|

| Trade Term: | CFR |

| Payment Terms: | L/C |

| Supply Ability: | 8000 Ton/per Month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Binzhou, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 1-473 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | HX |

| Top client Serviced: | SIEMENS, American GE, FRANCE ALSTOM, French energy power, Vale of Brazil |

| Certificates: | 1. ISO9000, ISO14000, ISO18000 by BV France. 2. EN-1090 CE certificate, American CWI, European TWI, European IWE |

| Standard: | American code European code ASTM standard |

| Service Offered: | Design, fabrication, packing, transport, erection |

| Installation: | Engineer are able to stay at site to direct construction |

| Production Capacity: | 8000 Ton/per Month |

| Packing: | Components will be packaged by steel pallet |

| Delivery Date: | usually as customers'order |

Product Description

1. Typical Surface treatment for advantage steel building ( made of steel frame ) :

Surface Treatment |

Hot dip galvanize |

Standard : JIS , DIN , ASTM B695 - 2000 |

Hot dip galvanizing hole cutting good looking on surface |

Galvanizing process : Steel structural components → Degreasing → Rinsing→ Pickling → Rinsing → Fluxing → Galvanizing → Quenching → (Passivation) → Inspecting → Finished Product |

Paint |

1 . Primer paint one coat 20 - 30 um |

2 . Middle paint two coat 40 - 60 um |

3 . Finish paint one coat 20 - 30 um Paint type : 1 . red primer 2 . zinc primer 3 . Alkyd primer |

2. About the product:

1) Product scope:

advantage steel building ( made of steel frame ), steel structure warehouse / workshop / hangar / garage / poultry house, high rise steel building, industrial steel frame, sandwich panel, welded H steel, C/Z channel, corrugated steel sheet, etc.

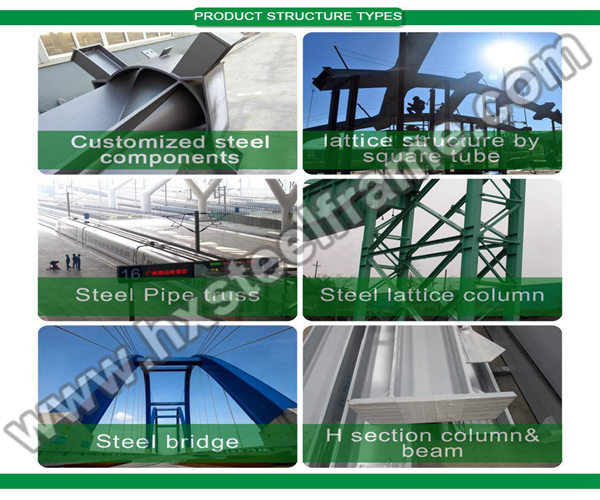

2) Products structure type& Service:

Design & fabrication & Engineering Service, Steel Building, Space Frames, lattice steel structure, Tubular Steel Structures, basic building elements( built-up welded H-section, hot-rolled H-section, channel, steel column, steel beam), standard frames, secondary framing, roof & wall materials.

3. Project case- Ningxia prefabricated steel structure workshop, 23000 SQM:

main structure:welding H steel or round steel

knee brace: Angle steel

roof ridge: corrugated steel sheet

Wrapping cover:color steel sheet

roof gutter: color steel sheet

rain spout: PVC pipe

doors: sliding sandwich panel door or metal door

windows: PVC OR ALUMINUM WINDOW

connecting: high strength bolts

characteristic: environment-friendly

lower cost and maintenance easily

4. DESIGN STANDARD& SOFTWARE for advantage steel building ( made of steel frame ) :

Standard: America Standard, Australia Standard, England Standard, China Standard, etc.

Software: SAP2000, Auto CAD, PKPM, RSTAB, PROE, MTS, Tekla Structures( Xsteel) , 3D3S, Tarch, etc.

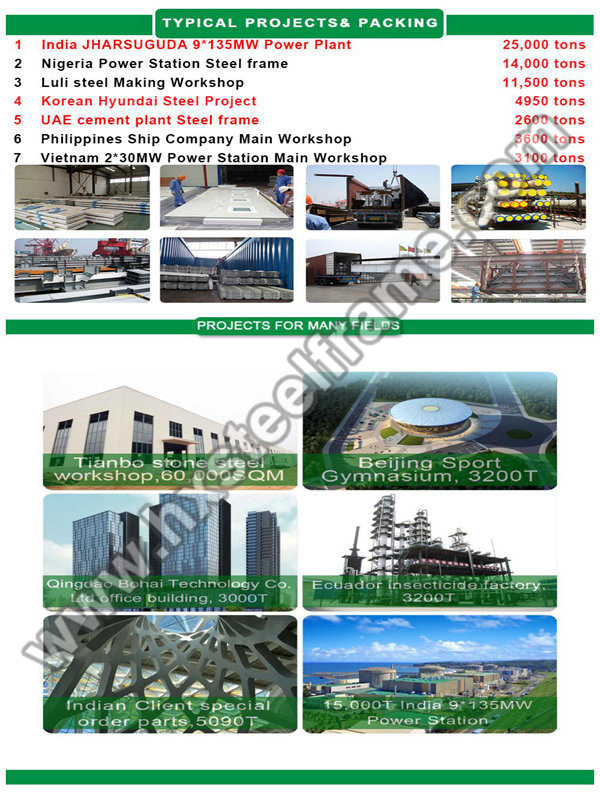

5. Our seaworthy packing system for advantage steel building ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) Do you provide on-site installation service for advantage steel building ( made of steel frame ) ?

We provides customers with one-stop integrated steel building solution including installation and operation. We have 3 options for on-site installation according to the customer' s specific situation. Firstly, we offer installation instructions and installation video. Secondly, we assign the installation team for the project. Finally, we send professional engineer to guide the local installation team.

2) What' s your delivery time of your advantage steel building ( made of steel frame ) ?

Salesman will confirm the time accordingly, large order should communicate with order management department in advance. Normally, delivery time is 45days after receive deposit. Large order delivery time should be arranged separately.