tubular steel structures formed metal buildings outdoor to Mogadishu market

| Min. Order: | 50 Metric Ton |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 3000 Ton/per Week |

| Place of Origin: | Shandong |

Company Profile

| Location: | Binzhou, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 1-270 |

|---|---|

| Means of Transport: | Land |

| Brand Name: | HX |

| Top client Serviced: | SIEMENS, American GE, FRANCE ALSTOM, French energy power, Vale of Brazil |

| Certificates: | 1. ISO9000, ISO14000, ISO18000 by BV France. 2. EN-1090 CE certificate, American CWI, European TWI, European IWE |

| Material Grade: | JIS SS400 Grade Q235, equivalent to ASTM A36 |

| Standard: | Australian standard American standard European standard |

| Surface Treatment: | painted with PPG |

| Production Capacity: | 3000 Ton/per Week |

| Packing: | Bolts and accessories loaded into wooden box |

| Delivery Date: | 30 days |

Product Description

1. Our Design & Engineering Services for the Steel building ( made of tubular steel structures ) :

1 ) Experienced and skilled team of designers including CAD designers and 3D designers has the capacity to deliver outstanding designs for your project .

2 ) Simple design service is free of charge to all clients to ensure customer .

If you require more complex engineering of structures such as load baring capacities we can also provide this service requiring designer fee .

3 ) We look forward to delivering exceptional designs and advice for your project .

Installation supervision and after-sales service :

If needed , we will dispatch our professional workers to conduct assembling guide or technical support for you on site .

2. Why choose us as your steel structure supplier:

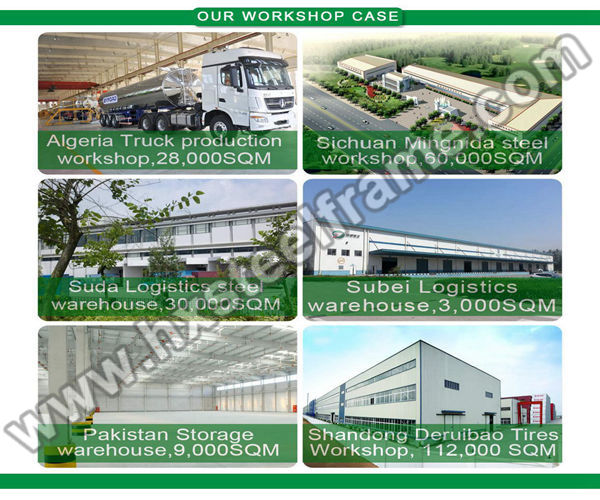

Founded in Shandong province, we are a professional manufacturer of steel structure building, workshop, warehouse, high rise building, industrial steel structure, civil steel structure, sandwich panel and profiled steel with ISO9001, SGS and CE certification.

We once made 30, 000 SQM prefabricated building in 16 days for a major buyer in Saudi Arabia. And, we manufactured 200, 000 square meter of prefabricated steel building monthly for post-Wenchuan Earthquake reconstruction. Our daily capacity is large 5, 0000 square meter and this is how we manage it:

1) 200, 000 square meter of factory space

2) 10 production lines for our prefabricated building series, 960 workers

3) 200 workers in charge of overseas construction

4) Our sales representatives can reply to your inquiries within eight hours in English, French and Japanese.

5) Two hundred workers oversee overseas construction.

6) We passed quality tests by India Adani Power, Hyundai Steel, China Construction Group, China Railway Construction Group and other biggest companies in the world.

3. Project case- Angola steel structure project, 18800m2:

In 2003, Our company took over the workshop steel structure project of an Angola company, the steel structure building has been completed by now. The whole steel structure building area is 18800m2. This steel structure is particularly special, it has a certain technical difficulties. In order to carry on the project installing smoothly, Our company sent an outstanding engineer to direct the installation of the steel structure building. With 3 months hard work, we completed the project perfect finally. The customer was very satisfied with our work and gave the new steel structure workshop project drawing to us, we were excited about this. This indicates that the customer is well accepted with our steel structure production and they trust Our company. Therefore, we will work harder to make more satisfying steel structure for customers.

4. We found international surface treatment system for the Steel building ( made of tubular steel structures ) :

We got NACE 1 and 2 level certificate as per American standard.

We build professional enclosed shot blasting workshop, enclosed sand blasting room, 34000m2 fully-enclosed painting workshop and 20, 000 m2 enclosed packing workshop.

5. Our seaworthy packing system for Steel building ( made of tubular steel structures ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) What will client provide before factory offers good quotation ?

A: When we receive inquiry from client, client need to fills purchasing intention sheet, providing us with information of steel workshop dimensions, draft drawing, wind load etc for prefabricated steel building. We will design the drawings and offer competitive quotation with the above information.

2) What are main materials of Steel building ( made of tubular steel structures ) ?

A: Its materials mainly include light steel structure, sandwich panel, roof tile, door, window, covers, screws and other accessories.

3) Could you please design a new and unique Steel building ( made of tubular steel structures ) for me ?

A: Absolutely! We are able to provide you with construction scheme

and structural drawings as per your specific demand and favors. Besides, detailed drawings and 3Dmodels are surely included. One-stop service is our outstanding superiority with no doubt.