prefabricated building structure and metal building structure of three story

| Min. Order: | 100 Metric Ton |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C |

| Supply Ability: | 9000 Ton/per Month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Binzhou, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 1-619 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | HX |

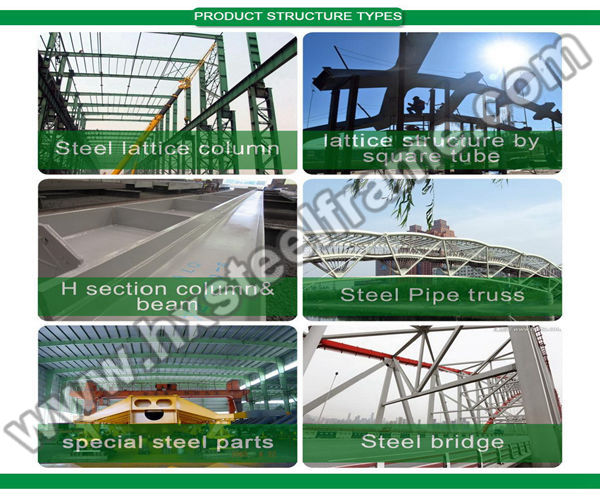

| Main structure: | Welded H section,Lattice structure,Tubular column or beam,space frame etc |

| Design& quote: | We can make design and quotation according to your require or your drawing |

| Drawing Design: | by us |

| Surface Treatment: | Sand blasting Shot blasting |

| Top client Serviced: | SIEMENS, American GE, FRANCE ALSTOM, French energy power, Vale of Brazil |

| Production Capacity: | 9000 Ton/per Month |

| Packing: | Sandwich panels covered with plastic film |

| Delivery Date: | 20 days |

Product Description

1. Technical specs of the prefabricated building structure ( made of steel frame ) :

The prefabricated building structure ( made of steel frame ) were designed , constructed and installed by us who are professional on designing , processing and installing of steel structure building . You may give us your own drawings to enable us construct as per your request or you might just give us your ideas , we can design the project based on your ideas . Buildings of steel structure are safe , easy to install and disassemble . This steel structure can be used multiple times without special tools .

1 ) size :

MOQ is 1000 square meter , length X width X eave height , roof slope

2 ) type :

single slope , double slope , muti-slope ; single span ,

double-span , Multi-span , single floor , double floors

3 ) base :

Concrete and steel foundation bolts

4 ) column and beam :

material Q345 ( S355JR ) or Q235 ( S235JR ) steel , all bolts connection , straight cross-section or Variable cross-section

5 ) bracing :

X or V or other type bracing made from angle , round pipe etc .

6 ) c or z purlin ,

size from C100 ~ C320 , Z160 ~ Z300

7 ) roof and wall panel :

single colorful corrugated steel sheet 0.326 ~ 0.6mm thick , YX26-205-820 ( 820mm wide )

single colorful corrugated steel sheet 0.326 ~ 0.6mm thick , YX15-225-900 ( 900mm wide )

single colorful corrugated steel sheet 0.326 ~ 0.6mm thick , YX35-125-750 ( 750mm wide )

single colorful corrugated steel sheet 0.376 ~ 0.6mm thick , YX51-380-760 ( 760mm wide )

single colorful corrugated steel sheet 0.376 ~ 0.6mm thick , YX51-470 ( 470mm wide )

sandwich panel with EPS , rock wool , glass wool , PU etc insulation thickness around 50mm ~ 150mm , width 950mm or 960mm !

8 ) accessories :

Semi - transparent skylight belts , Ventilators , down pipe , out gutter etc

9 ) surface :

Paint or hot dip galvanized

10 ) packing :

main steel frame without packing load in 40'OT , roof and wall panel load in 40' HQ

2. About us:

Our company commenced its operations in 2004, and pioneered the high-end metal building products market in China. We have been the first mover in China, right from workshop, high rise building, prefabricated building structure ( made of steel frame ) etc to all kinds of pre-engineered buildings.

Today, we are a leading turnkey Pre-Engineered Steel building Construction Solution provider in China with integrated facilities for design, manufacture, logistics, supply and project execution capabilities for pre-engineered steel buildings. We holds a significant part of market share in Asia for metal building systems. We works in close association with industry leaders in project development and construction, providing support to critical industrial, commercial and infrastructure projects.

We are also a certified green building partner and all our products comply with international green norms.

3. Project case- Congo Hebe Fabrication Petro-chemical Plant Module:

Product Description

Type 1 steel warehouse( 2500 m2) details:

A. Length: 130m

B. 10 meters between the 7 main frames

C. Height: 10 meters inside

D. Slope for roof: 23%

E. Aluminium panels for Roof with 35um coating thickness

F. 10T Overhead bridge Crane( also known as dual-beam bridge / gantry crane bridge

G. The Congo client need the side walls( only 3 sides) , for the 4th side, quoting a self collapsing gate

4. The surface treatment for our prefabricated building structure ( made of steel frame ) :

We have pretty good preservative treatment for steel frame as follows as per the highest international surface treatment code:

1) Clean the steel( reach to Sa2.5 Grade, China Code) , then we will spray paint:

Two layer epoxy zinc rich primer and 2 layer anti-rust paint( total thickness: 100-120um) ; Warranty period: 18-20 years under normal conditions.

2) Hot-dipped galvanized, when the thickness of parts is less than 5mm, thickness of hot-dipped gal is more than 65um; when equal to or more than 5mm, that is more than 86um. Warranty period: 45-50 years under normal conditions.

5. Our seaworthy packing system for prefabricated building structure ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) Why I should choose your company ?

A: Firstly, we are the real factory, all range of steel structure products are manufactured on our production line. Now we already have two production base, we can guarantee our product and ensure the delivery time. We can manufacture the products which meet your special demand and we will do everything in our power to turn out the satisfaction to you. Secondly, we have professional foreign trade team with high efficiency communications and we can give you professional solutions. We will work hard and strive towards our service concept of " Zero-Defect Quality, Zero-Distance service and Zero-Complaint Service ". Thirdly, we have good business relationship with our partners and we have extends business to over thirty countries in Western Europe, Southeast Asia, Africa and South America. We will keep researching and developing, to provide more and more excellent products and perfect service to all customers.