steel building workshop made of steel frame hot Sell precisely painted cut

| Min. Order: | 100 Metric Ton |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 9000 Ton/per Month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Binzhou, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 1-761 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | HX |

| Top client Serviced: | SIEMENS, American GE, FRANCE ALSTOM, French energy power, Vale of Brazil |

| Drawing Design: | dwgs Detailing by us |

| Surface Treatment: | Painted by Zinc rich paint Painted by Epoxy paint |

| Certificates:: | 2. EN-1090 CE certificate, American CWI, European TWI, European IWE |

| Standard: | European code ASTM standard CE certification |

| Production Capacity: | 9000 Ton/per Month |

| Packing: | sea worthy packing |

| Delivery Date: | 20 days |

Product Description

1. Technical parameters for steel building workshop ( made of steel frame ) :

Size | According to customer's requirements |

Standard | GB , DIN , JIS , BS , ASTM |

Material | Q235 ; Q345 |

Surface treatment | Painted with epoxy paint or zinc rich paint |

Package | In bundle or pallet or according to the requirements of customers |

Delivery | Container or Bulk |

Shipment Time | According to the quantity and specification of each order |

Production Usage | Used in industrial or civil fields |

Product Characteristics | 1 . Fine gloss exterior , anti-corrosive 2 . High strength , satisfactory property of the steel 3 . Anti-seismic , wind resistance , environmental protection 4 . Fire- resistant , clean and health 5 . 50-year-long life expectancy |

Remark | Payment terms : T/T, L/C |

Terms of trade | FOB , CFR , CIF , EXW |

2. About us:

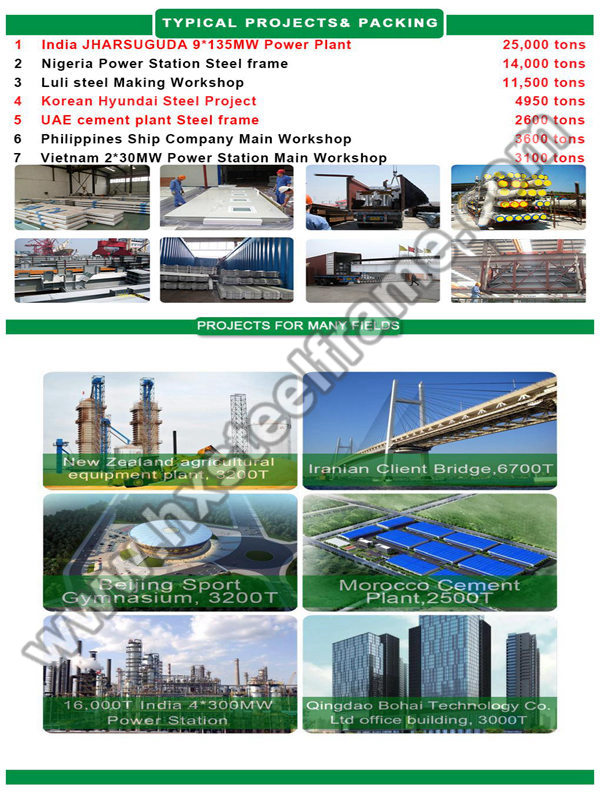

We are a modern steel structure building enterprise specialized in engineering design, manufacture, installation and service of steel structures; and its manufacturing base is situated in Shandong, China. Due to customers' trust and constant innovation of our team, the enterprise is now with a total area of 360, 000 m2 as regards our plants.

We have passed ISO9001: 2000 International Quality System Certification and has a level-one qualification of steel structure project specialized contracting. The enterprise has been verified by BV and SGS which are two global largest verification organizations.

The business scope of us are various steel building, such as steel structure workshop, warehouse, multi-storey building, prefab steel house, container steel house, high-rise frame building and frame structure for large equipment, etc. We also supply various steel structure materials, such as H-type steel, color steel sheet, C-type purlin, Z-type purlin, floor deck as well as steel beam and steel column.

3. Project case- Description of Hengda steel structure workshop building:

The axis area for this steel structure workshop building is 19578m2

Axis dimension is 180m, 108m, the eave height is 14.15meters.

The primary member is Q345B, all are sand-blasting,

The surface treatment quality required meets GB 8923 SA 2 1/2 Grade

Painting is two coats of anti-corrosive primer and two alkyd finish

Crane runway girder is equipped in each span, install 32mt and 16mt overhead crane

4. Professional technical and management team for steel building workshop ( made of steel frame ) :

1) Full solution for steel structure design. We can offer design as per your requirement for the steel building, like workshop, warehouse, high rise building, steel building workshop ( made of steel frame ) etc

2) Procurement and Manufacture for all material for prefabricated building

We have a professional procurement team to make sure all the materials are with good quality and all from China top steel mills. And our factory operation under ISO standard, to make sure the fabrication works with high technology.

3) Site management & Installation supervision

We could send our engineers to help for the installation supervision, you just need to prepare a team which know normal construction works will be OK.

5. Our seaworthy packing system for steel building workshop ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) Is there a clear service life of your steel building workshop ( made of steel frame ) ? If have, how long ?

Under conventional climate and environment, steel structure whole building 30 years, main structure 50 years, protecting system 30 years.

2) What designs do you have in different climates? How can the steel building workshop ( made of steel frame ) adopt to different climates?

Strong wind region: improve the wind-resisting ability of the internal structure.

Cold region: increase the thickness of the wall, or use good insulation material, improve anti-pressure ability of the structure.

High corrosion region: use corrosion resistant material, or paint anti-corrosive coating.