structural steel beams and columns for metal building structure for Kampala client

| Min. Order: | 50 Metric Ton |

|---|---|

| Trade Term: | CIF |

| Payment Terms: | T/T |

| Supply Ability: | 9000 Ton/per Month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Binzhou, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 1-251 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | HX |

| Drawing Design: | by us |

| Software used: | AUTOCAD 3D3S PKPM Tekla |

| Service Offered: | Design, fabrication, packing, transport |

| Top client Serviced: | SIEMENS, American GE, FRANCE ALSTOM, French energy power, Vale of Brazil |

| Installation: | Provide full set of construction drawings and video to direct installation |

| Production Capacity: | 9000 Ton/per Month |

| Packing: | sea worthy packing |

| Delivery Date: | 30 days |

Product Description

1. Data of the Steel building ( made of structural steel beams and columns ) :

Specification | |

Material : | Grade Q235 , equivalent to ASTM A36 Grade Q345 , equivalent to ASTM A572 |

Section : | Any product shape according to customer's requirements |

Certification : | ISO quality system , Chinese GB50221 - 2001 |

Sand Blast : | SA 2.5 Sand blasting |

Welding Technology : | Single level butt welding , fillet welding by electric arc welding , and Gas shielded welding |

Surface treatment : | Hot dip galvanized , Epoxy zinc rich primer Standard : ISO1461 ( 1999 ) , JIS H 8641 - 1999 , ASTM A 123 / A 123M-02 |

Welding Testing | Ultrasonic Testing , X-ray Testing |

Manufacturing Technology | Drilling , Cutting , Assembling , Welding , Rectification , Testing etc |

2. Why choose us as your steel structure supplier:

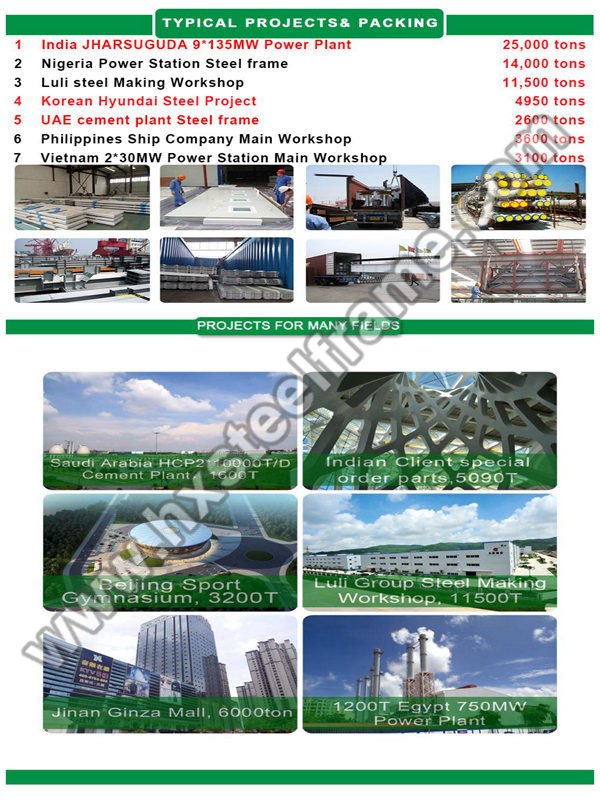

Founded in Shandong province, we are a professional manufacturer of steel structure building, workshop, warehouse, high rise building, industrial steel structure, civil steel structure, sandwich panel and profiled steel with ISO9001, SGS and CE certification.

We once made 30, 000 SQM prefabricated building in 16 days for a major buyer in Saudi Arabia. And, we manufactured 200, 000 square meter of prefabricated steel building monthly for post-Wenchuan Earthquake reconstruction. Our daily capacity is large 5, 0000 square meter and this is how we manage it:

1) 200, 000 square meter of factory space

2) 10 production lines for our prefabricated building series, 960 workers

3) 200 workers in charge of overseas construction

4) Our sales representatives can reply to your inquiries within eight hours in English, French and Japanese.

5) Two hundred workers oversee overseas construction.

6) We passed quality tests by India Adani Power, Hyundai Steel, China Construction Group, China Railway Construction Group and other biggest companies in the world.

3. Project case- Qilu Petro-chemical Heavy Steel Workshop:

Size: 55000 square meter workshop, Single Span 39m, eave height 18m, mainly loading bear steel member over 100Ton, totally quantity of steel 6000Ton.

Steel Column: Q345B Four tube lattice column. Painted: 120um epoxy zinc painted.

Roof Structure: Q235B Pipe Truss Structure. Painted: 120um epoxy zinc painted.

Crane Beam: Q345B H section Steel Beam. Painted: 120um epoxy zinc painted.

Secondary Structure

Roof Horizontal Bracing: Q235B Angle Steel, Painted: three layer white color anti-rust Alkyd painted

Wall X Cross Bracing: Q235B Double Angle Steel, Painted: three layer white color anti-rust Alkyd painted

Tie Beam: Q235B Welding Pipe, Painted: three layer white color anti-rust Alkyd painted.

Roof Purlin: Galvanized C section steel

Wall Purlin: Galvanized C section steel

Steel Rod: Galvanized Steel Rod.

Panel system

Roof: 0.5mm Single Color sheet

Wall: 0.5mm Single Color sheet

4. We found international surface treatment system for the Steel building ( made of structural steel beams and columns ) :

We got NACE 1 and 2 level certificate as per American standard.

We build professional enclosed shot blasting workshop, enclosed sand blasting room, 34000m2 fully-enclosed painting workshop and 20, 000 m2 enclosed packing workshop.

5. Our seaworthy packing system for Steel building ( made of structural steel beams and columns ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) Do you have your own factory ?

Yes, we have our own factory. Our company has been engaged in steel construction field for 30 years. We set several independent workshops for steel structure and color steel sheet and sandwich panels. In addition we are well-equipped with professional designers, experienced techies and sales team. You can visit our factory any time!

2) What are your main products ?

steel structure, steel structure building, prefab building, sandwich panel, handrails, Steel building ( made of structural steel beams and columns ) and other building material. The shape, material, model, color, treatment technology of them can be customized according to your requirements.

3) How can I obtain a price for your Steel building ( made of structural steel beams and columns ) ?

Tell us your requirements on the qty, dwgs, material details such as steel grade etc and we will quota for you ASAP.