steel tube structure and Pre-engineered Steel Frame produce for Lima buyer

| Min. Order: | 50 Metric Ton |

|---|---|

| Trade Term: | CIF |

| Payment Terms: | T/T |

| Supply Ability: | 9000 Ton/per Month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Binzhou, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 1-241 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | HX |

| Software used: | American SAP2000 American STAAD-Pro Finland Xsteel |

| Service Offered: | Design, fabrication, packing, transport |

| Shipment by: | Shipment: 20'GP, 40'GP, 40'HQ, or in bulk |

| Design& quote: | We can make design and quotation according to your require or your drawing |

| Top client Serviced: | SIEMENS, American GE, FRANCE ALSTOM, French energy power, Vale of Brazil |

| Production Capacity: | 9000 Ton/per Month |

| Packing: | Bolts and accessories loaded into wooden box |

| Delivery Date: | 30 days |

Product Description

1. Products description for the Steel building ( made of steel tube structure ) :

Main Steel | |

Steel Beam Column | Q235B , Q345B |

Secondary Steel | |

Tie Bar | Q235B |

Purlin | C and Z purlin |

Bracing | Q235B |

Accessories | |

Surface | Painted or Hot Dip Galvanized |

Door | Rolling Up Door or Sliding Door |

Window | PVC or Aluminum Alloy |

Roof and Wall Panels | Corrugated Steel Sheet , EPS Sandwich Panel , Rock Wool Sandwich Panel , PU Sandwich Panel |

Others | |

Service | Design , Fabrication and Installation |

We can offer quotations according to customers' drawings and requirements , free design drawings and detailed installation drawings . | |

Design software : Auto CAD , PKPM , MTS , 3D3S , TArch , Tekla Structures ( X steel ) V12.0 , etc | |

Packing | main steel frame with 40 OT roof and panel load in 40 HQ Or According To Customer Requirement |

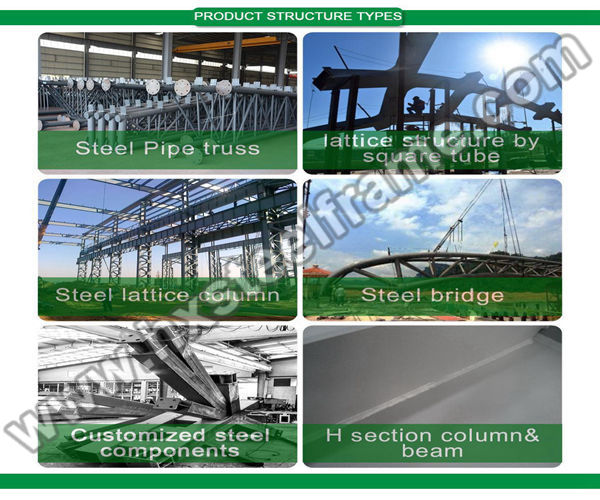

2. Our products scope cover all kinds of steel structure for civil and industrial fields:

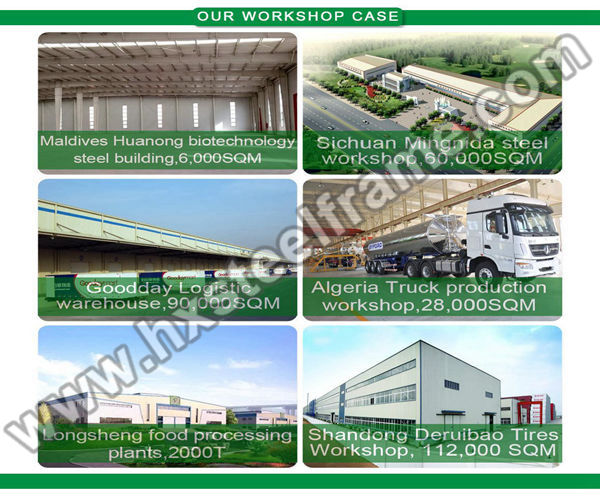

As one of the largest structural steel fabricators in China targeting global structural steel market. It takes full advantage of industry-leading technology and advanced equipment, extensive project management skills and high English proficiency, coupled with on-time, on-budget performance, and earns the trusts and supports from the worlds' top clients in a variety of sectors across the globe. As a steel structure solutions leader, we are dedicated to providing professional services for users in various industries, our project covers all kinds of steel structure for civil and industrial fields, like Power Plant [ Incl. HRSG( NPP) & Ducts; ACC; Conveyor] , Oil Gas & Chemicals, Metal & Mining, Commercial Building, steel workshop, high rise building, Theme Park, Modularization and Fireproofing, etc.

With its four well equipped fabrication shops, we have delivered over 300,000 metric tons of fabricated steel structure to the global until now.

3. Project case- Qilu Petro-chemical Heavy Steel Workshop:

Size: 55000 square meter workshop, Single Span 39m, eave height 18m, mainly loading bear steel member over 100Ton, totally quantity of steel 6000Ton.

Steel Column: Q345B Four tube lattice column. Painted: 120um epoxy zinc painted.

Roof Structure: Q235B Pipe Truss Structure. Painted: 120um epoxy zinc painted.

Crane Beam: Q345B H section Steel Beam. Painted: 120um epoxy zinc painted.

Secondary Structure

Roof Horizontal Bracing: Q235B Angle Steel, Painted: three layer white color anti-rust Alkyd painted

Wall X Cross Bracing: Q235B Double Angle Steel, Painted: three layer white color anti-rust Alkyd painted

Tie Beam: Q235B Welding Pipe, Painted: three layer white color anti-rust Alkyd painted.

Roof Purlin: Galvanized C section steel

Wall Purlin: Galvanized C section steel

Steel Rod: Galvanized Steel Rod.

Panel system

Roof: 0.5mm Single Color sheet

Wall: 0.5mm Single Color sheet

4. We found international surface treatment system for the Steel building ( made of steel tube structure ) :

We got NACE 1 and 2 level certificate as per American standard.

We build professional enclosed shot blasting workshop, enclosed sand blasting room, 34000m2 fully-enclosed painting workshop and 20, 000 m2 enclosed packing workshop.

5. Our seaworthy packing system for Steel building ( made of steel tube structure ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) How to install Steel building ( made of steel tube structure ) ?

Reply: We will furnish you the detailed construction drawing and the construction manual which could help you to erect and install the building step by step. We also could send the engineer to your local to help you if need. if you have no work teams, we can send our professional teams to install for you.

2) Storage Life of Steel building ( made of steel tube structure ) ?

Reply: All steel structure frame life is more than 50 Years, all cladding sheets are about 20 Years.

3) How can you deal with deformation when welding ?

We select suitable welding method, material and sequence as specified material required.