steel tube columns and Pre-engineered Steel Frame for Germany client

| Min. Order: | 120 Metric Ton |

|---|---|

| Trade Term: | CIF |

| Payment Terms: | T/T |

| Supply Ability: | 8000 Ton/per Month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Binzhou, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 1-240 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | HX |

| Service Offered: | Design, fabrication, packing, transport, erection |

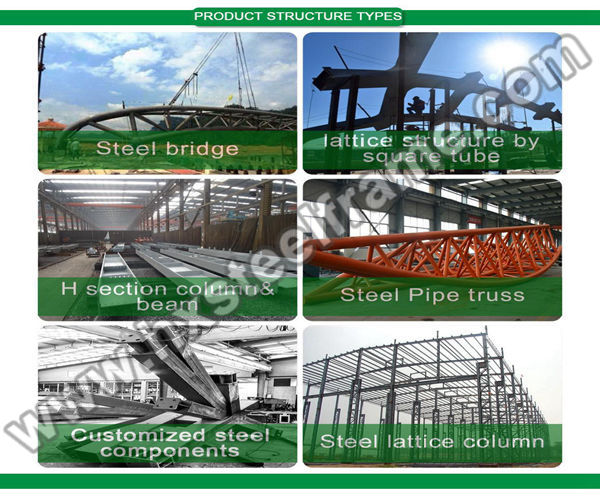

| Main structure: | Welded H section,Lattice structure,Tubular column or beam,space frame etc |

| Specifications: | Column&Beam: Welded or Hot rolled H-section |

| Quality Control: | The third party, SGS, ASIA INSPECTION all accept |

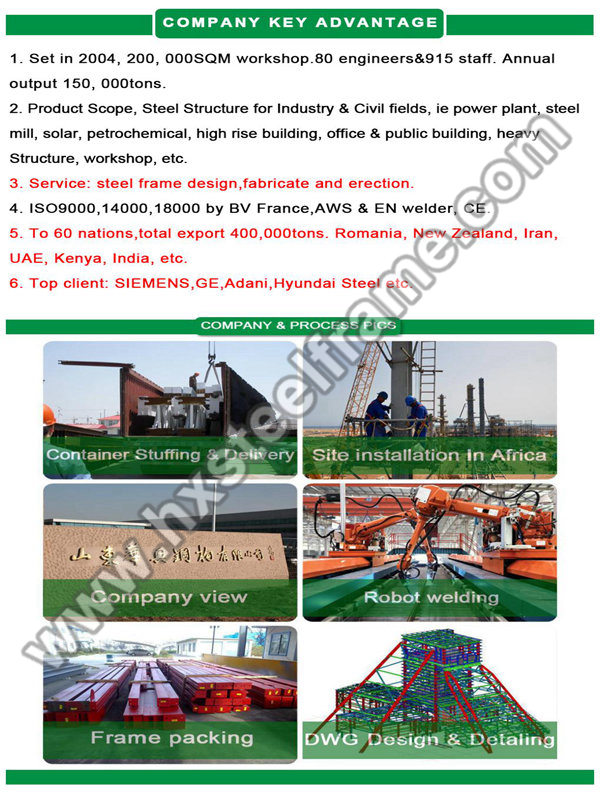

| Top client Serviced: | SIEMENS, American GE, FRANCE ALSTOM, French energy power, Vale of Brazil |

| Production Capacity: | 8000 Ton/per Month |

| Packing: | Sandwich panels covered with plastic film |

| Delivery Date: | 20 days |

Product Description

1. Technical specs for the Steel building ( made of steel tube columns ) :

Item name | Material characteristics | Material Grade | Surface Treatment |

Anchor bolt | Steel rod M24 , M27 | Q235B | |

Steel Column | H shape , Box , steel pipe , Hot rolled sheet | Q235B , Q345B | Paint or Hot dip galvanized |

H shape , steel Truss , Hot rolled sheet | Q235B , Q345B | Paint or Hot dip galvanized | |

Steel Bracing | Steel rod , Steel pipe , Angle steel | Q235B , Q345B | Paint |

Steel Purlin | C or Z shape , steel purlin Thickness :1.8mm ~ 3.0mm | Q235B , Q345B | Hot dip galvanized |

External wall panel , Roof panel | Sandwich panel with EPS , Rock wool , Pu , Glass wool | Steel T = 0.426 ~ 0.8mm , insulation T=50 ~ 150mm | Alu-zinc galvanized then painted |

Door | Sliding or rolling door | Steel or Aluminum sheet , T = 1.0 ~ 1.5mm | Paint or Hot dip galvanized |

Window | alloy-Glass , Aluminium alloy - shutter | T = 1.0 ~ 2.0mm | Alloy |

Day-lighting panel | FRP , T = 1.5mm or T = 1.8mm | Coefficient of thermal expansion : 2.2 x 10 - 5 / cm | Light transmittance 85% |

Ventilator | Turbine ventilator, ventilator along a slope | Steel , stainless steel , PC | Paint , 304 |

Gutter | Galvanized Steel plate , stainless steel plate | T = 2.0mm | Paint , 304 |

Downpipe | PVC pipe , T = 0.5mm | Φ110 , 160 , 200 | |

Bolt | Ordinary , high strength | 10.9S , 4.8s | Bluing for high strength bolts |

2. We supply both common steel building and the special steel structure:

Besides structural steel building like workshop, warehouse, high rise building, Steel building ( made of steel tube columns ) etc, we can also do nonstandard structural steel member fabrication according to client' s sample or drawings, like special shape structures, board girder, industrial steel frames, belt conveyor and other supporting frames, steel gallery, reclaimer and deck parts etc.

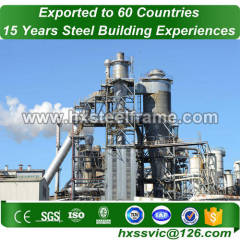

3. Project case- Binzhou Tianhong Steel Structure Chemical Plant, 4500 tons:

We work as subcontractor fabricated Steel Structure for Chemical Plant, project including Detail Engineer Plan, Fabrication, Steel Structure including Equipment Platform, Pipe Bridge, Tank Structure, Steel Platform, Handrail, Ladder, we also supply the Grating and Stair Treads.

The steel structure with the advantage of quickly installation, all the steel structure fabricated in workshop and delivery to the project site for installation, connected by high strength bolt, fast and easy installation greatly shorten the construction time which reduce the costs, the whole structure is easy in maintenance, which can be used for more than 50 years.

1) Equipment Framework

Equipment Framework bear the Equipment, Framework Structure mainly welding H Steel.

2) Pipe Bridge

Pipe Bridge mainly support the pipe, truss structure, the Angle Steel and H section steel connected by welding or bolt, the structure divide upper booms,bottom booms, web member etc.

3) Steel Platform

Steel Platform is convenient for several equipment operation, Maintenance and repair.

4. Engineering design advantage for the Steel building ( made of steel tube columns ) :

Our people have a good knowledge and full grasp of various PEB specifications and international codes, which are predominant building specifications and standards in America, Europe and worldwide, such as BS, MBMA, AISC, AISI and so forth. We have fully developed a proprietary technical system that targets the tasks of PEB engineering, engineering optimization, and further engineering. Our engineering people are also versed in utilization and application of main-stream commercial design software including STAAD, SAP2000, PKPM, STRUCAD, XSTEEL etc.

Our company owes its competitiveness, in great part, to its flexibility, efficiency and optimization of designs for structure and cladding. Our structural engineers are not only masters in terms of structural design, but also extremely professional and skillful in cladding system design. They are intimately familiar with categories, functions, combinations and applications of different types of roof and wall panels. Therefore the building system we offer our customers is simply more human-friendly, safer and more cost-effective and features greater architectural beauty.

5. Our seaworthy packing system for Steel building ( made of steel tube columns ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) How to control the quality of your Steel building ( made of steel tube columns ) ?

a. quality of the design: think about possible problems in advance and provide a high quality design solution.

b. quality of the raw material: choose the qualified raw material from the top steel mill in China.

c. quality of the production: precise manufacturing technique, experienced workers, strict quality inspection.

2) How to deal with quality problems of your Steel building ( made of steel tube columns ) ?

Warranty is 2 years. Within the warranty period, we will responsible for all quality problems caused by production.