prebuilt shops building and modular commercial buildings wind-resistance

| Min. Order: | 100 Metric Ton |

|---|---|

| Trade Term: | CFR |

| Payment Terms: | T/T |

| Supply Ability: | 10000 Ton/per Month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Binzhou, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 1-926 |

|---|---|

| Means of Transport: | Land |

| Brand Name: | HX |

| Top client Serviced: | SIEMENS, American GE, FRANCE ALSTOM, French energy power, Vale of Brazil |

| Material Grade: | European S235& S355 |

| Surface Treatment: | Painted or HDG or As Customer demand |

| Drawing Design: | by client or by us |

| Service Offered: | Design, fabrication, packing, transport, erection |

| Production Capacity: | 10000 Ton/per Month |

| Packing: | Panel accessories will be packaged in wooden box; |

| Delivery Date: | 15 to 40 days |

Product Description

1. Product Details for prebuilt shops building ( made of steel frame ) :

Main frame | ||

1 | Main steel structure

( columns and beams ) | 1 . Steel Q345 ( S355JR ) or Q235 ( S235JR ) H shape 2 . Straight cross-section or Variable cross - section |

2 | Sub steel structure | 1 . Material Q235 ( S235JR ) steel 2 . Bolt connections . Anti-rust painted or galvanized . 3 . Bracing :X - type or V - type or other type bracing made from angle , round pipe , etc 4 . Purlins : C or Z type : Size from C120 ~ C320 , Z100 ~ Z200 |

Maintenance system | ||

3 | Roof | Sandwich panel ( PU / EPS / fiberglass / rook wool ) or Colorful steel tile |

4 | Wall | Sandwich panel ( PU / EPS / fiberglass / rook wool ) or Colorful steel tile |

Doors | Steel rolling shutter or others | |

Windows | Alu. Alloy window , or others | |

Fitting | ||

7 | Edge Cover | Steel sheet 0.5mm thickness |

8 | Bolts | M24 , M22 , M16 embedded bolts , intensive bolts , galvanized ordinary bolts , high-strength bolts , etc |

9 | Others options | Day - lighting panel , Roof ventilator , Down pipe , Galvanized , Crane , sanitary Products , etc |

10 | Foundation | Cement and steel foundation bolts |

2. About our company:

1) We have a group of professional engineers, most of whom has more than 10 years' experiences in architecture field.

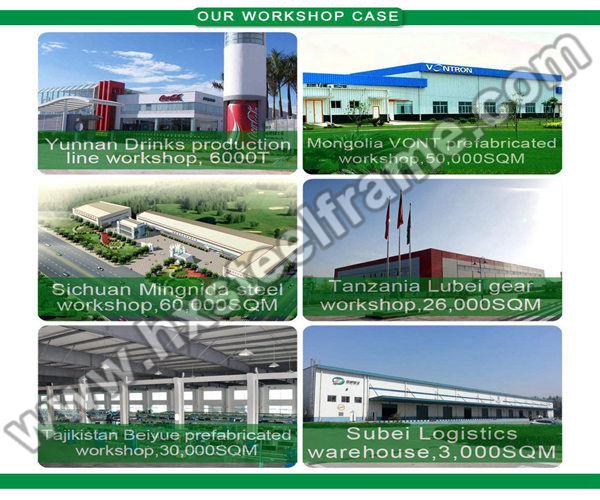

2) Established for more than ten years, our company has got a various of experiences in all kinds of steel structure& steel building design, manufacture, installation and so on. The work staffs have excellent skills. Some of them had helped customers to install the warehouse around the world.

3) We have the capacity of annually 200,000 tons steel structure. We also have possessed more than 300 sets of large precise and advanced processing equipment, including large gantry planning machines, automatic submerged arc welding machines, assembling machines, shot blasting machines and so on.

3. Market covered:

Euro-market: German, England, French, Russia, Georgia

The American market: USA, Canada, Venezuela

Oceania market: Australia, New Zealand, Samoa

The Africa market: Angola, Algeria, Ghana

4. How we ensure the high quality of prebuilt shops building ( made of steel frame ) :

After years of exploration, practice and improvement, our company has built an experienced technical team in steel structure. Every project is supposed to go through the following procedures:

1) Owing plasma cutting, flame cutting, available to provide multiple cutting service.

2) Well-experienced engineer team and production team for steel structure fabrication, welder working with CWI certificate, according to WPS( welding procedure specification) and PQR( procedure qualification record) .

3) Professional non-destructive testing, fully equipped.

4) Professional surface treatment: sandblasting, paint spraying, powder coating as per American standard.

5) More than 10 years steel structure fabrication experience

6) Full set of manufacturing process plan to ensure delivery on time.

5. Our seaworthy packing system for prebuilt shops building ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) Do you accept container loading inspection ?

A: You are welcomed to send an inspector, not only for the container loading, but any time during the production time.

2) Whats the terms of payment and the shipment for your product of prebuilt shops building ( made of steel frame ) ?

A: We can accept the payment by T/ T, L/ C, but we suggest the T/ T, it will be convenient and fast for the order. For the shipment, we can send the goods by Sea. The customers also can choose their own shipping company.

3) What do you do for prebuilt shops building ( made of steel frame )?

We design, manufacture, install and service all kinds of steel structure building, steel workshop, steel warehouse etc.