steel buidings and steel building construction top quality hot sale in Ukraine

| Min. Order: | 120 Metric Ton |

|---|---|

| Trade Term: | CFR |

| Payment Terms: | T/T |

| Supply Ability: | 10000 Ton/per Month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Binzhou, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 1-415 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | HX |

| Top client Serviced: | SIEMENS, American GE, FRANCE ALSTOM, French energy power, Vale of Brazil |

| Certificates: | 1. ISO9000, ISO14000, ISO18000 by BV France. 2. EN-1090 CE certificate, American CWI, European TWI, European IWE |

| Material Grade: | ASTM A36& A572 JIS SS400 |

| Surface Treatment: | painted with PPG painted with international paint |

| Drawing Design: | by client or by us |

| Production Capacity: | 10000 Ton/per Month |

| Packing: | Bolts and accessories loaded into wooden box |

| Delivery Date: | 15 to 40 days |

Product Description

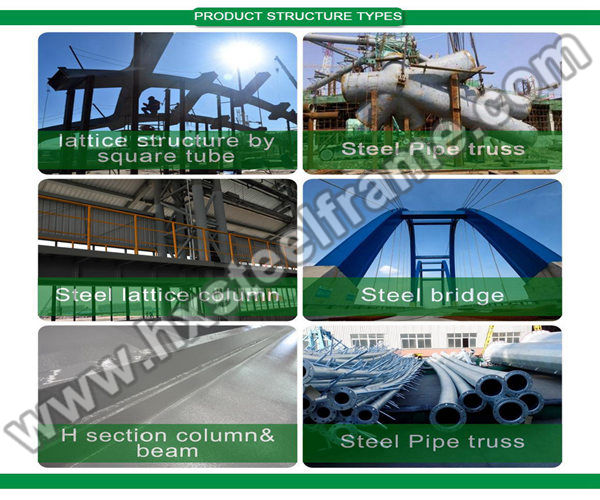

1. Specifications of the steel buidings ( made of steel frame ) :

Main steel frame : | H section steel beam and columns |

Secondary frame : | Galvanized C / Z purlin , steel bracing , tied bar , knee brace , edge cover etc . |

Roof & Wall panel : | Sandwich panel , corrugated steel sheet or skylight panel |

Tie Rod : | Circular Steel Tube |

Brace : | Round Bar |

Knee Brace : | Angle Steel |

Roof Gutter : | Color Steel Sheet or galvanized Steel sheet |

Rainspout : | PVC Pipe |

Door : | Swing door , sliding door or roller door |

Windows : | PVC steel or Aluminum Alloy Window |

Connecting : | Anchor bolt , high-strength bolt , common bolt |

Drawing : | We can make the design and quotation according to your requirement or your drawing |

Installation : | Provide full set of construction drawings and video to direct installation ; Engineer are able to stay at site to direct construction |

2. Company Advantages:

Our Corporation is able to offer complete services for pre-engineered buildings and steel structure projects including: design, fabrication, erection and after-sales services. This integrated production process will bring to our customers huge advantages of an optimal solution, high-quality products and perfect services.

WHAT MAKES US DIFFERENT ?

1) Competitive price

The advanced self-contained high automatic design production line along with experienced and professional staffs help us to bring out the most competitive price.

2) Quality assurance

We produces all structural components of pre-engineered buildings, steel structure projects at the factory with ISO 9001: 2008 quality control system. we have a Quality Control Department who guarantees our products to meet international standards.

3) Fast delivery

With 200, 000 m2 of manufacturing factory and a professional highly trained erection team who is strictly supervised by project management board, we are committed to manufacturing and provide products on schedule.

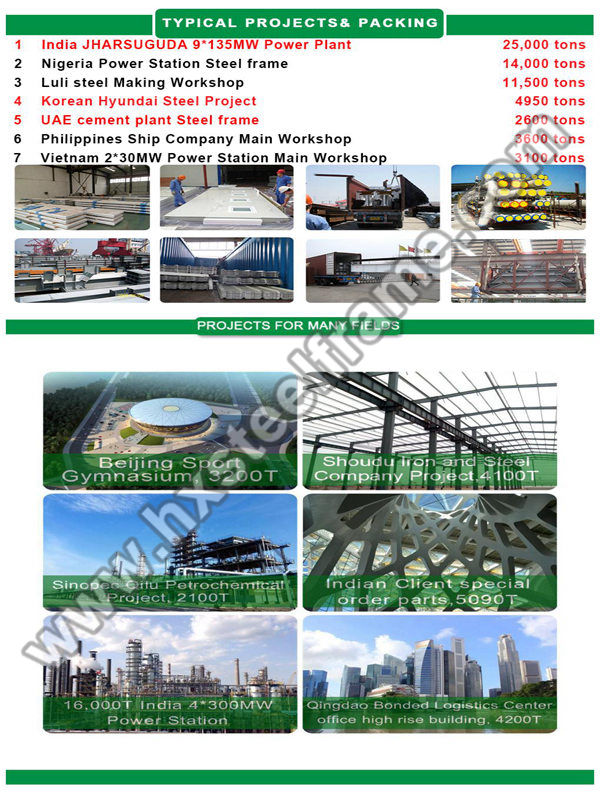

3. Project case- Congo Steel Sheet Making Factory project, 2016:

Project Overview:

Beam & Column structure with large span curved cellular rafters. Package included structural steel work, stairs, balustrading and steel decking.

Main Contractor: MAPA Group

Engineer: Five Consulting Engineers

Tonnage: 2800

Completion Date: 2016

Due to the tight schedule of this project, to save the time and improve the container delivery efficiency, we use our container stuffing equipment from Germany, which could make us finish one 40 feet container stuffing within 2 minutes. The client and owner are all surprised to see our container stuffing system. What is more important and make them amazing, the goods are 100% brand new and without any damage after reach to project site. This help the owner get many prize from the local government.

4. Our technical team' s ability for steel buidings ( made of steel frame ) :

1) We have 80 persons' design team with more than 20 years experience, who can provide the most reasonable proposal. We can offer AutoCAD proposal drawing according to your ideas, customer's drawing are welcomed. Clear span without middle column can reach to 30 meters.

2) 3D photos for pre-view how' s your building looks like is available.

3) Blueprint drawing is available.

4) Professional production drawing control excellent quality.

5) Very details installation drawing. Engineer on-site guidance is available

5. Our seaworthy packing system for steel buidings ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) How to install steel buidings ( made of steel frame ) ?

Reply: We will furnish you the detailed construction drawing and the construction manual which could help you to erect and install the building step by step. We also could send the engineer to your local to help you if need. if you have no work teams, we can send our professional teams to install for you.

2) Storage Life of steel buidings ( made of steel frame ) ?

Reply: All steel structure frame life is more than 50 Years, all cladding sheets are about 20 Years.

3) How can you deal with deformation when welding ?

We select suitable welding method, material and sequence as specified material required.