modular office building made of structure light long life hot sale in Senegal

| Min. Order: | 50 Metric Ton |

|---|---|

| Trade Term: | CFR |

| Payment Terms: | L/C |

| Supply Ability: | 8000 Ton/per Month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Binzhou, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 1-920 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | HX |

| Top client Serviced: | SIEMENS, American GE, FRANCE ALSTOM, French energy power, Vale of Brazil |

| Surface Treatment: | painted with JOTUN |

| Drawing Design: | by client or by us |

| Service Offered: | Design, fabrication, packing, transport, erection |

| Shipment by: | Container or bulk ship |

| Production Capacity: | 8000 Ton/per Month |

| Packing: | sea worthy packing |

| Delivery Date: | usually as customers'order |

Product Description

1. Why give the production job of modular office building ( made of steel frame ) to us :

1) CNC punching machine , CNC bending machine , CNC welding machine , plasma cutting , high-power laser cutting and water jet cutting . available to provide multiple cutting service .

2) Well-experienced engineer team and production team for steel structure fabrication , welder working with CWI certificate , according to WPS ( welding procedure specification ) and PQR ( procedure qualification record ) .

3) Professional non-destructive testing , fully equipped .

4) Four painting line can supply high and quickly painting service . Professional surface treatment : hot-dip galvanizing , sandblasting , paint spraying , powder coating , plating .

5) More than 8 years in steel structure experience .

6) Full set of manufacturing process plan to ensure delivery on time .

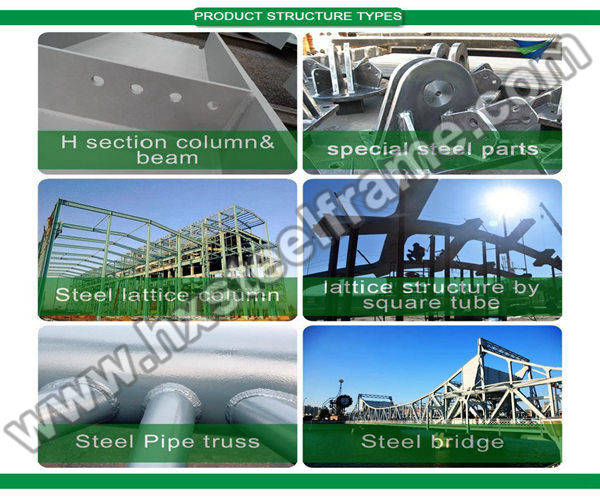

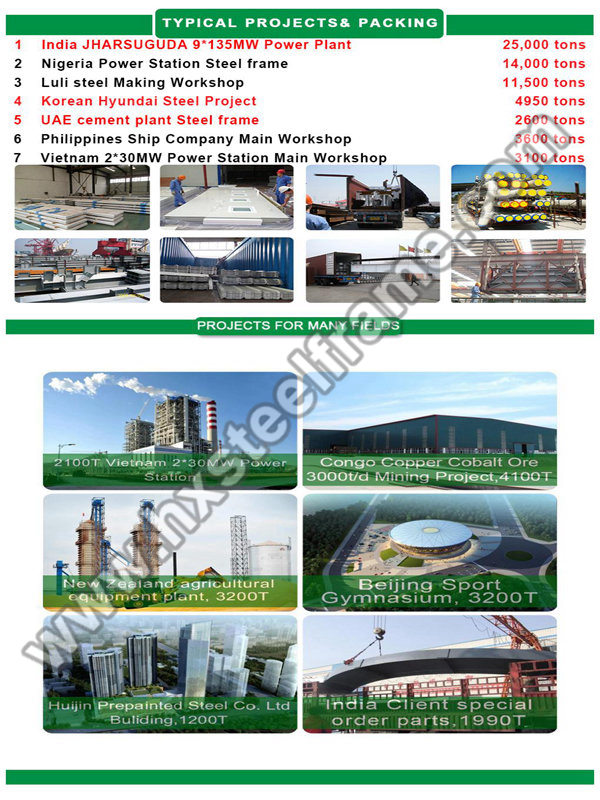

2. Our Products Scope:

1) Steel Structure for industrial and power fields, such as power plant, steel mill, solar industry, hydroelectric plant, petrochemical fields, oil and gas pipeline, etc.

2) Steel Structure for civil fields, like high-rise building, heavy Steel Structure, workshop& warehouse, etc.

3. Project case- Angola steel structure project, 18800m2:

In 2003, Our company took over the workshop steel structure project of an Angola company, the steel structure building has been completed by now. The whole steel structure building area is 18800m2. This steel structure is particularly special, it has a certain technical difficulties. In order to carry on the project installing smoothly, Our company sent an outstanding engineer to direct the installation of the steel structure building. With 3 months hard work, we completed the project perfect finally. The customer was very satisfied with our work and gave the new steel structure workshop project drawing to us, we were excited about this. This indicates that the customer is well accepted with our steel structure production and they trust Our company. Therefore, we will work harder to make more satisfying steel structure for customers.

4. How we ensure the high quality of modular office building ( made of steel frame ) :

After years of exploration, practice and improvement, our company has built an experienced technical team in steel structure. Every project is supposed to go through the following procedures:

1) Owing plasma cutting, flame cutting, available to provide multiple cutting service.

2) Well-experienced engineer team and production team for steel structure fabrication, welder working with CWI certificate, according to WPS( welding procedure specification) and PQR( procedure qualification record) .

3) Professional non-destructive testing, fully equipped.

4) Professional surface treatment: sandblasting, paint spraying, powder coating as per American standard.

5) More than 10 years steel structure fabrication experience

6) Full set of manufacturing process plan to ensure delivery on time.

5. Our seaworthy packing system for modular office building ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) Is there a clear service life of your modular office building ( made of steel frame ) ? If have, how long ?

Under conventional climate and environment, steel structure whole building 30 years, main structure 50 years, protecting system 30 years.

2) What designs do you have in different climates? How can the modular office building ( made of steel frame ) adopt to different climates?

Strong wind region: improve the wind-resisting ability of the internal structure.

Cold region: increase the thickness of the wall, or use good insulation material, improve anti-pressure ability of the structure.

High corrosion region: use corrosion resistant material, or paint anti-corrosive coating.