steel structure assembly formed long span building with ISO at Finland area

| Min. Order: | 50 Metric Ton |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C |

| Supply Ability: | 3000 Ton/per Week |

| Place of Origin: | Shandong |

Company Profile

| Location: | Binzhou, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 1-234 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | HX |

| Drawing Design: | by client or by us |

| Software used: | AUTOCAD 3D3S PKPM |

| Service Offered: | Design, fabrication, packing, transport, erection |

| Top client Serviced: | SIEMENS, American GE, FRANCE ALSTOM, French energy power, Vale of Brazil |

| Shipment by: | Container or bulk ship |

| Production Capacity: | 3000 Ton/per Week |

| Packing: | Bolts and accessories loaded into wooden box |

| Delivery Date: | 30 days |

Product Description

1. Characteristics of Steel building ( made of steel structure assembly ) :

Steel structure is widely used as warehouse , factory , hotel , church , garage etc . It is durable , economic and environmental .

Main Grade : Q345B , Q235B

Standard : ISO9001 : 2008

We are a Factory-direct provider of all kinds of steel structure buildings and material plant . We specialize in design , fabricate construction , install and related technology guide . Our competitive price and high quality have got customers from all over the word .

Applications :

Used as Steel workshop / warehouse / shed , Exhibition Hall , Office buildings , Garage , Multi-story building , Hanger , Agricultural storage , Logistic centers , and all kinds of steel materials etc .

Specifications :

Main Steel : Q345B , Q235B

Column&Beam : Welded or Hot rolled H-section

Wall&Roof : EPS , Rock wall , PU sandwich , corrugated steel sheet

Door : Rolled up door or Sliding door

Window : Plastic steel or Aluminum alloy window

Surface : Hot dip galvanized or painted . ( all colors we can do )

Crane : 5T , 10T , 15T , etc .

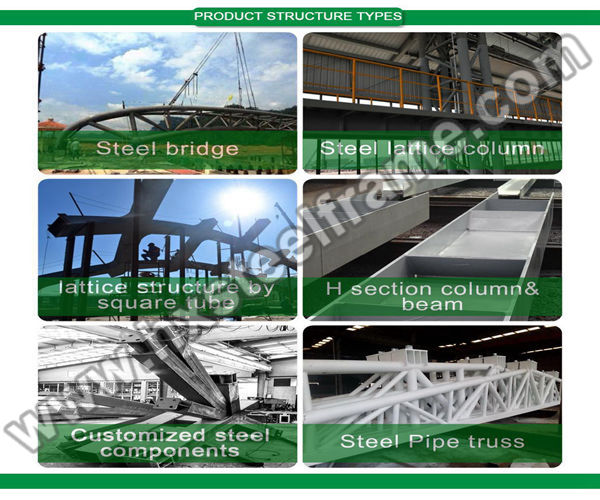

2. Our business and products scope:

Our company is dedicated to steel framed buildings, from research, design, manufacture, installation and after-sales service. We mainly provide a comprehensive range of steel structure products, including multi-storey high-rise buildings( for commercial offices, hotels, residents, etc.), light steel structure system( for warehouse, workshop, supermarket etc.) and the wide-span steel structure system( for airport, exhibition center, stadium, etc. ) , Steel building ( made of steel structure assembly ) etc. Additionally, service of technology consult is available.

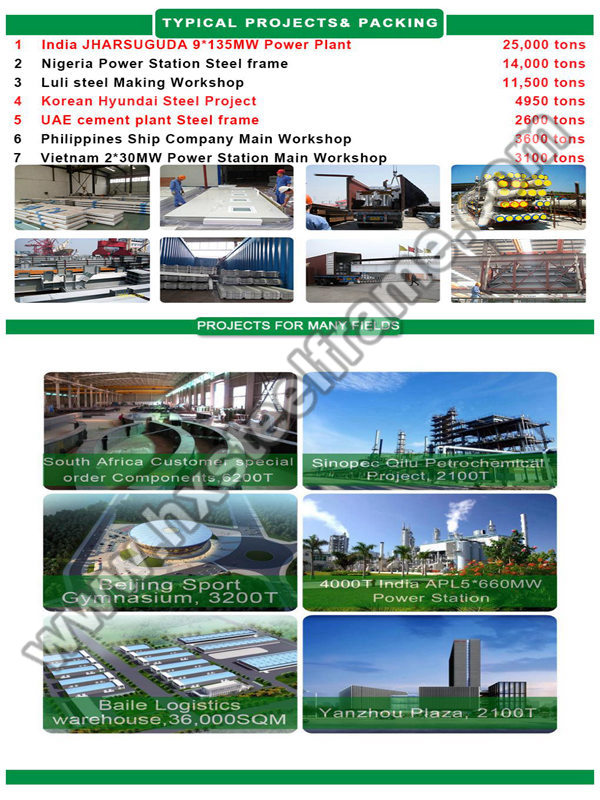

3. Some of OUR WORKSHOP/ WAREHOUSE PROJECTS:

1) AREVA Transformer Factory Project:

Covering an area totaled 33, 842 sq.m, the program consumed steel in 4299 tons, the column height is 31-33 m, and the inside is installed with the bunk bed traveling crane with the maximum hoisting capacity in 400 tons.

2) NEW ZEALAND Barns / Grain Warehouses:

light gauge steel structure with cold bended profiles.

3) BOLIVIA Cement Plant:

Steel consumption: 3, 655 tons in the first phase, 7200 tons in the second phase.

4) LDK Polysilicon Public Project:

Was generally contracted by FLR CO., LTD, the total steel consumption volume for Phase I project reached over 3000 tons and this program was in a high-rise steel structure of 4-7 floors.

4. Engineering design advantage for the Steel building ( made of steel structure assembly ) :

Our people have a good knowledge and full grasp of various PEB specifications and international codes, which are predominant building specifications and standards in America, Europe and worldwide, such as BS, MBMA, AISC, AISI and so forth. We have fully developed a proprietary technical system that targets the tasks of PEB engineering, engineering optimization, and further engineering. Our engineering people are also versed in utilization and application of main-stream commercial design software including STAAD, SAP2000, PKPM, STRUCAD, XSTEEL etc.

Our company owes its competitiveness, in great part, to its flexibility, efficiency and optimization of designs for structure and cladding. Our structural engineers are not only masters in terms of structural design, but also extremely professional and skillful in cladding system design. They are intimately familiar with categories, functions, combinations and applications of different types of roof and wall panels. Therefore the building system we offer our customers is simply more human-friendly, safer and more cost-effective and features greater architectural beauty.

5. Our seaworthy packing system for Steel building ( made of steel structure assembly ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) How about the derust grade of your Steel building ( made of steel structure assembly ) ?

Reply: Ball blasting Sa2.5 on main steel structure or by Galvanized frame;

manual derust St2.5 on secondary steel structure.

2) What kind of panel used for the roof and wall ?

Reply: Color corrugated steel sheet and sandwich panel could be used. Sandwich panel performs well on the heat insulation, sound insulation. Common sandwich materials are EPS, glass wool and PU sandwich panels.

3) Are Steel building ( made of steel structure assembly ) expensive ?

Answer: The steel structure of our company is economic. Its technology and materials used decreases waste expenses such as wood, decorative stone, brick etc. All the material including the steel frames, wall body and roof for installation are prefabricated during the production process, therefore the labor costs for installation is decreased.