metal warehouse buildings made of steel stucture multi-span for Gambia client

| Min. Order: | 120 Metric Ton |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 3000 Ton/per Week |

| Place of Origin: | Shandong |

Company Profile

| Location: | Binzhou, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 1-727 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | HX |

| Top client Serviced: | SIEMENS, American GE, FRANCE ALSTOM, French energy power, Vale of Brazil |

| Material Grade: | Chinese Q235& Q345B ASTM A36& A992 European S235& S355 |

| Standard: | CE certification CE ISO standard |

| Surface Treatment: | painted with international paint painted with Hempel |

| Drawing Design: | by client by us |

| Production Capacity: | 3000 Ton/per Week |

| Packing: | Components will be packaged by steel pallet |

| Delivery Date: | 30 days |

Product Description

1. metal warehouse buildings ( made of steel frame ) main components description :

1 ) Mainly made by H - section and box girder .

Wide flanges make H - beam have a higher lateral stiffness fit for compression member .

Flanges of H - section with same thickness parallel with one another have strong resistance to bending , easy to composite and joint with other component for your prefab steel structure workshop .

2 ) Support System

Support system of prefab steel structure workshop mainly consist of purlin , cross bracing and angle brace made by Z - section , C - section or angle , allot the payload of column and pillar , transfer the loading to whole frame .

Support system makes the frame structure stand as a unity ; improve the solidity and stabilization of frame itself .

3 ) Roof and wall panel system

Roof and wall panel system mainly made of color steel or color steel sandwich panel .

Roof and wall panel system connected by self-tapping screw , easy and fast to assemble .

Good mechanical property as well as bearing capacity of prefab steel structure workshop .

Multiple color and surface finishing available meet your customization requirement and preference for prefab steel structure workshop .

2. Why choose us as your steel structure supplier:

Founded in Shandong province, we are a professional manufacturer of steel structure building, workshop, warehouse, high rise building, industrial steel structure, civil steel structure, sandwich panel and profiled steel with ISO9001, SGS and CE certification.

We once made 30, 000 SQM prefabricated building in 16 days for a major buyer in Saudi Arabia. And, we manufactured 200, 000 square meter of prefabricated steel building monthly for post-Wenchuan Earthquake reconstruction. Our daily capacity is large 5, 0000 square meter and this is how we manage it:

1) 200, 000 square meter of factory space

2) 10 production lines for our prefabricated building series, 960 workers

3) 200 workers in charge of overseas construction

4) Our sales representatives can reply to your inquiries within eight hours in English, French and Japanese.

5) Two hundred workers oversee overseas construction.

6) We passed quality tests by India Adani Power, Hyundai Steel, China Construction Group, China Railway Construction Group and other biggest companies in the world.

3. Project case- Hunan Volkswagen CAR ACCESSORY CO., LTD( 2013) :

This project includes the processing workshop( 12500 m2) , end products storage( 3600m2) , and a logistics center. The main processing is 12m high, with 48m span. All steel parts including steel main frame, secondary frame and cladding system are manufactured and supplied by us.

4. Certification for metal warehouse buildings ( made of steel frame ) :

We are always committed to the development of steel structure. By far we have achieved the following certificates:

CE EN1090 certification

Quality Management System Certification ISO9001: 2008, by BV France

Environment Management System Certification ISO14001: 2004, by BV France

Occupational Health and Safety Management System Certification, by BV France

CWI certificate

TWI certificate

ASME certificate

AWS welder certificate etc.

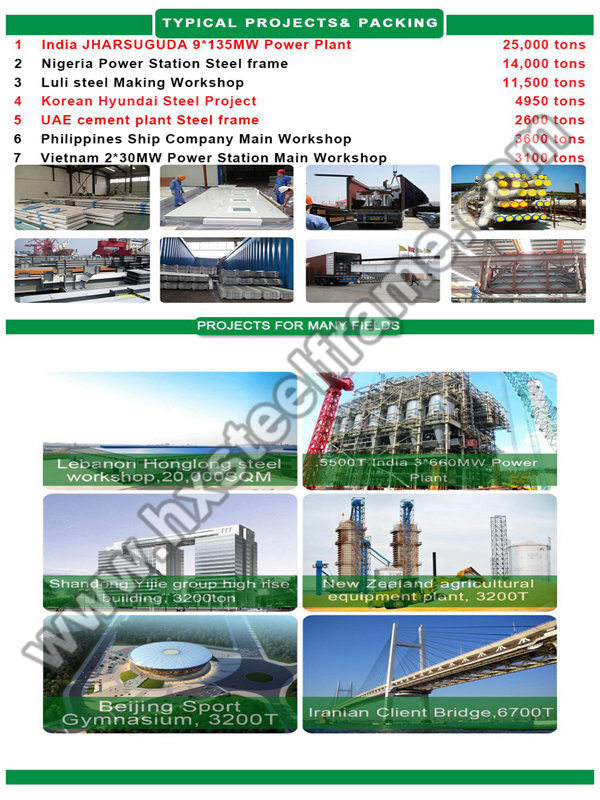

5. Our seaworthy packing system for metal warehouse buildings ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) How to install metal warehouse buildings ( made of steel frame ) ?

Reply: We will furnish you the detailed construction drawing and the construction manual which could help you to erect and install the building step by step. We also could send the engineer to your local to help you if need. if you have no work teams, we can send our professional teams to install for you.

2) Storage Life of metal warehouse buildings ( made of steel frame ) ?

Reply: All steel structure frame life is more than 50 Years, all cladding sheets are about 20 Years.

3) How can you deal with deformation when welding ?

We select suitable welding method, material and sequence as specified material required.