Heavy Steel Workshop and Prefab Steel workshop recyclable to Somalia market

| Min. Order: | 120 Metric Ton |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 3000 Ton/per Week |

| Place of Origin: | Shandong |

Company Profile

| Location: | Binzhou, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 1-706 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | HX |

| Top client Serviced: | SIEMENS, American GE, FRANCE ALSTOM, French energy power, Vale of Brazil |

| Specifications:: | Wall&Roof: EPS, Rock wall, PU sandwich, corrugated steel sheet |

| Welding standard: | AWS D1.1 |

| Standard: | AISI, ASTM, BS, DIN, GB, JIS Australian standard |

| Service Offered: | Design, fabrication, packing, transport, erection |

| Production Capacity: | 3000 Ton/per Week |

| Packing: | Panel accessories will be packaged in wooden box; |

| Delivery Date: | usually as customers'order |

Product Description

1. Fill the Table below and Sent It to Us, to Get Your Free Proposal for Heavy Steel Workshop ( made of steel frame ) :

Your location | Country ________ State ________ City _______ Postal code ________ |

Size | Length ________ meter Width ________ meter Height ________ meter |

Storey | Storey number ________ |

Wind Load | ________ km / hour |

Snow Load | ________ kn / m² |

Anti - earthquake | ________ magnitude |

Roof Normal Payload | ________ kg / m² |

Brick wall needed or not | If needed , brick height ________ |

Thermal insulation if needed | If needed , EPS panel , PU sandwich panel Glass wool panel , Rock wool panel are optional . If needed , normal pre-painted steel tile will be used for your project . |

Crane if needed | If needed , _____ units , max lifting weight ____ tons ; max lifting height _____ m |

Storage Cargo condition | If additional requirement for anti-corrosive |

2. About us:

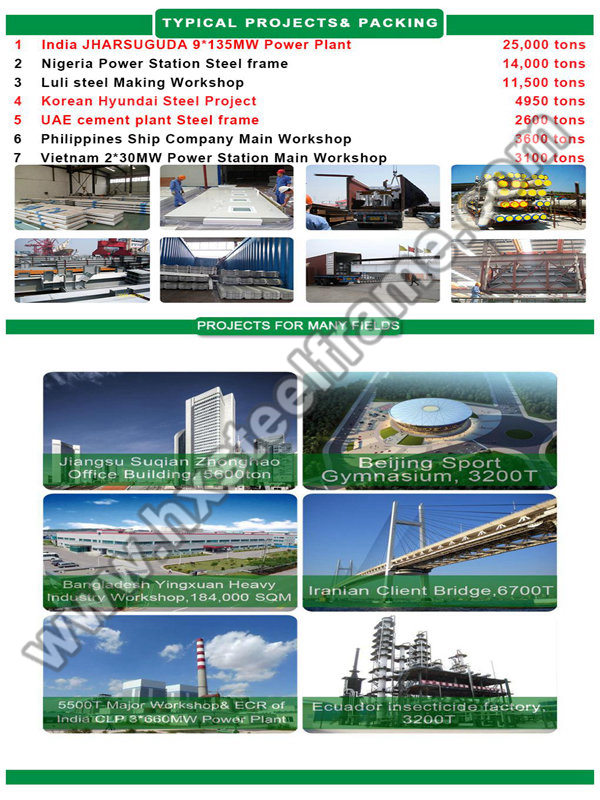

Founded in Shandong province, we have been engaged in construction field for more than 14 years. Today we have become a company integrating R & D, design, production, sales, installation and service. Our main products range from steel structure, steel workshop, warehouse, prefab steel building, ( color coated and galvanized corrugated) steel sheet ( for roof, wall) , sandwich panel ( EPS, PU, Rock Wool, glass wool) , C, H, Z section steel and also other building materials.We have more than 10 independent production lines.

Our products are mainly used as the workshop, warehouse, office and accommodation in such fields as construction, petroleum, water conservation, exploration, mining, military, traffic, urban construction, house and government procurement. With the advanced manufacturing technology, excellent product quality, complete product types, outstanding sales and service team, our product sales network covers both at home and abroad. We have also participate in many important projects in China and abroad including Beijing 2008 Olympic Games, China 60th anniversary of national parade village project, Sichuan Quake Relief and so on. Our products have been exported to more than 80 countries and regions like UAE, Saudi Arabia, Iraq, Ethiopia, Sudan, Angola, Equatorial Guinea, Gabon, Zambia etc.

3. Project case- AIRCRAFT HANGAR IN IRAN( 2013) :

The aircraft hangar in IRAN takes up 69M* 32M square meters with partial second floor. The eave height is 7.5meter, span is 32 meter. Drainage slope is 5% .

Main steel structure: welded H steel;

Purlin: cold-rolled C section steel;

Cladding: color steel sheet with foil insulation on roof and glass wool sandwich panels.

4. The surface treatment for our Heavy Steel Workshop ( made of steel frame ) :

We have pretty good preservative treatment for steel frame as follows as per the highest international surface treatment code:

1) Clean the steel( reach to Sa2.5 Grade, China Code) , then we will spray paint:

Two layer epoxy zinc rich primer and 2 layer anti-rust paint( total thickness: 100-120um) ; Warranty period: 18-20 years under normal conditions.

2) Hot-dipped galvanized, when the thickness of parts is less than 5mm, thickness of hot-dipped gal is more than 65um; when equal to or more than 5mm, that is more than 86um. Warranty period: 45-50 years under normal conditions.

5. Our seaworthy packing system for Heavy Steel Workshop ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) Price Term: FOB, CFR or CIF.

Shipping seaport: Qingdao Seaport. For FOB, CFR or CIF price, please specify which exact model steel building you need, and tell us your design data so that we can calculate the steel building cost, local transport charges and sea freight.

2) Payment: Typically 30% by T/ T as deposit, balance by T/ T before shipment. Other payment way can be negotiated.

3) Delivery: for 10000 SQM steel warehouse, goods can be ready for shipment about 1-2 months after receiving deposit.

4) How can I get a price for your Heavy Steel Workshop ( made of steel frame ) ?

Please send us your drawing; we can according to your drawing give you one price.

Or, give us your design data, we will design and quote to you.