equipment storage building and Prefab Steel workshop big-Span for Dubai client

| Min. Order: | 100 Metric Ton |

|---|---|

| Trade Term: | CFR |

| Payment Terms: | L/C |

| Supply Ability: | 8000 Ton/per Month |

| Place of Origin: | Shandong |

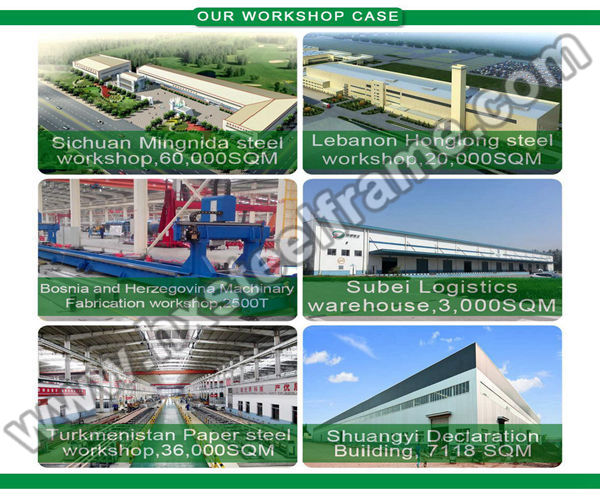

Company Profile

| Location: | Binzhou, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 1-702 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | HX |

| Top client Serviced: | SIEMENS, American GE, FRANCE ALSTOM, French energy power, Vale of Brazil |

| Material Grade: | Chinese Q235& Q345B ASTM A36& A992 |

| Standard: | CE certification CE ISO standard |

| Quality Control: | The third party, SGS, ASIA INSPECTION all accept |

| Installation: | Engineer are able to stay at site to direct construction. |

| Production Capacity: | 8000 Ton/per Month |

| Packing: | Panel accessories will be packaged in wooden box; |

| Delivery Date: | 15 to 40 days |

Product Description

1. Characteristics of equipment storage building ( made of steel frame ) :

Steel structure is widely used as warehouse , factory , hotel , church , garage etc . It is durable , economic and environmental .

Main Grade : Q345B , Q235B

Standard : ISO9001 : 2008

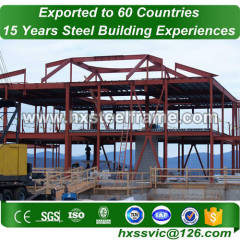

We are a Factory-direct provider of all kinds of steel structure buildings and material plant . We specialize in design , fabricate construction , install and related technology guide . Our competitive price and high quality have got customers from all over the word .

Applications :

Used as Steel workshop / warehouse / shed , Exhibition Hall , Office buildings , Garage , Multi-story building , Hanger , Agricultural storage , Logistic centers , and all kinds of steel materials etc .

Specifications :

Main Steel : Q345B , Q235B

Column&Beam : Welded or Hot rolled H-section

Wall&Roof : EPS , Rock wall , PU sandwich , corrugated steel sheet

Door : Rolled up door or Sliding door

Window : Plastic steel or Aluminum alloy window

Surface : Hot dip galvanized or painted . ( all colors we can do )

Crane : 5T , 10T , 15T , etc .

2. Company Advantages:

Our Corporation is able to offer complete services for pre-engineered buildings and steel structure projects including: design, fabrication, erection and after-sales services. This integrated production process will bring to our customers huge advantages of an optimal solution, high-quality products and perfect services.

WHAT MAKES US DIFFERENT ?

1) Competitive price

The advanced self-contained high automatic design production line along with experienced and professional staffs help us to bring out the most competitive price.

2) Quality assurance

We produces all structural components of pre-engineered buildings, steel structure projects at the factory with ISO 9001: 2008 quality control system. we have a Quality Control Department who guarantees our products to meet international standards.

3) Fast delivery

With 200, 000 m2 of manufacturing factory and a professional highly trained erection team who is strictly supervised by project management board, we are committed to manufacturing and provide products on schedule.

3. Project case- Hunan Volkswagen CAR ACCESSORY CO., LTD( 2013) :

This project includes the processing workshop( 12500 m2) , end products storage( 3600m2) , and a logistics center. The main processing is 12m high, with 48m span. All steel parts including steel main frame, secondary frame and cladding system are manufactured and supplied by us.

4. Drawings & Quotation for the equipment storage building ( made of steel frame ) :

1) Customized design to welcome.

2) As long as you like, we can design and provide drawings for you. Just give the technical data and your demand, we will give you the best offer.

3) In order to give you an exactly quotation and drawings, please tell us the Length, width, eave height and local weather. We'll quote for you prompt.

5. Our seaworthy packing system for equipment storage building ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) Would you send engineers to the site to guide for working when installed ?

Re: Yes, Usually we will send two engineers to the site, and the cost shall be in the customer account.

2) Can you design for equipment storage building ( made of steel frame ) ?

Re: Sure, we have excellent design team, our mainly design software are Auto CAD, PKPM, MTS, 3D3S, Tarch, Tekla Structures( Xsteel) V12.0.etc

3) Are you a factory, Can we visit your factory ?

Re: Yes, We are a professional manufacture of steel structure factory which has better cost advantage than trading company. Welcome you to visit our company.