prefabricated steel building and steel building construction of lowest Price

| Min. Order: | 100 Metric Ton |

|---|---|

| Trade Term: | CFR,CIF |

| Payment Terms: | L/C |

| Supply Ability: | 8000 Ton/per Month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Binzhou, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 1-404 |

|---|---|

| Means of Transport: | Land |

| Brand Name: | HX |

| Top client Serviced: | SIEMENS, American GE, FRANCE ALSTOM, French energy power, Vale of Brazil |

| Surface Treatment: | painted with international paint |

| Drawing Design: | by client or by us |

| Shipment by: | Container |

| Main structure: | Welded H section,Lattice structure,Tubular column or beam,space frame etc |

| Production Capacity: | 8000 Ton/per Month |

| Packing: | Sandwich panels covered with plastic film |

| Delivery Date: | 30 days |

Product Description

1. components and materials of the prefabricated steel building ( made of steel frame ) :

Main structure | Welded H section , Lattice structure , Tubular column or beam , space frame etc |

Purlin | C Section Channel or Z Section Channel |

Roof Cladding | Sandwich Panel or Corrugated Steel Sheet with Fiber Glass Wool Coil |

Wall Cladding | Sandwich Panel or Corrugated Steel Sheet |

Tie Rod | Circular Steel Tube |

Brace | Round Bar |

Column & Transverse Brace | Angle Steel or H Section Steel or Steel Pipe |

Knee Brace | Angle Steel |

Roof Gutter | Color Steel Sheet |

Rainspout | PVC Pipe |

Door | Sliding Sandwich Panel Door or Metal Door |

Windows | PVC/Plastic Steel/Aluminum Alloy Window |

Connecting | High Strength Bolts |

Packing | Decided by you , loaded into 1X 40ft GP , 1X20 ft GP , 1X40 ft HQ |

Drawing | We can make the design and quotation according to your require or your drawing |

2. Our company advantage:

1) Enough capacity

Our factory is occupies an area of 200000 m2, We have 1020 workers. 15, 000tons steel structure per month, So we have enough capacity for your demand on prefabricated steel building ( made of steel frame ) .

2) Advanced technology

There are 300 sets advanced technology equipment. The CNC cutting machines which are imported from USA to make sure the precise size be cut.

3) customized design

We have 62 senior design engineers, 25 shop dwg detailing engineers. our technology department can make a optimal design just for you review according your requirements and local weather condition.

3. Project case- Description of Hengda steel structure workshop building:

The axis area for this steel structure workshop building is 19578m2

Axis dimension is 180m, 108m, the eave height is 14.15meters.

The primary member is Q345B, all are sand-blasting,

The surface treatment quality required meets GB 8923 SA 2 1/2 Grade

Painting is two coats of anti-corrosive primer and two alkyd finish

Crane runway girder is equipped in each span, install 32mt and 16mt overhead crane

4. DESIGN STANDARD& SOFTWARE for prefabricated steel building ( made of steel frame ) :

Standard: America Standard, Australia Standard, England Standard, China Standard, etc.

Software: SAP2000, Auto CAD, PKPM, RSTAB, PROE, MTS, Tekla Structures( Xsteel) , 3D3S, Tarch, etc.

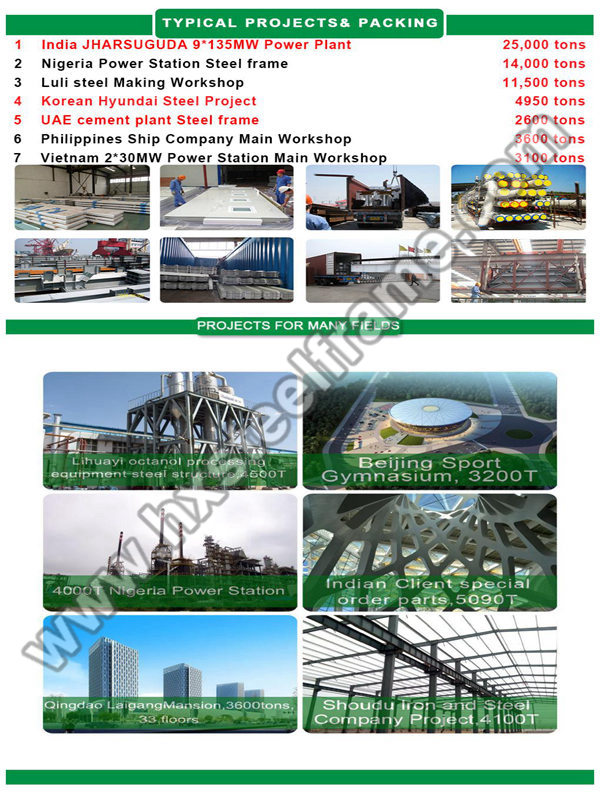

5. Our seaworthy packing system for prefabricated steel building ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) How to control the quality of your prefabricated steel building ( made of steel frame ) ?

a. quality of the design: think about possible problems in advance and provide a high quality design solution.

b. quality of the raw material: choose the qualified raw material from the top steel mill in China.

c. quality of the production: precise manufacturing technique, experienced workers, strict quality inspection.

2) How to deal with quality problems of your prefabricated steel building ( made of steel frame ) ?

Warranty is 2 years. Within the warranty period, we will responsible for all quality problems caused by production.