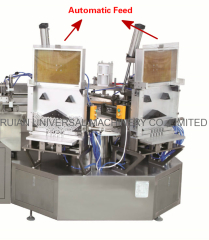

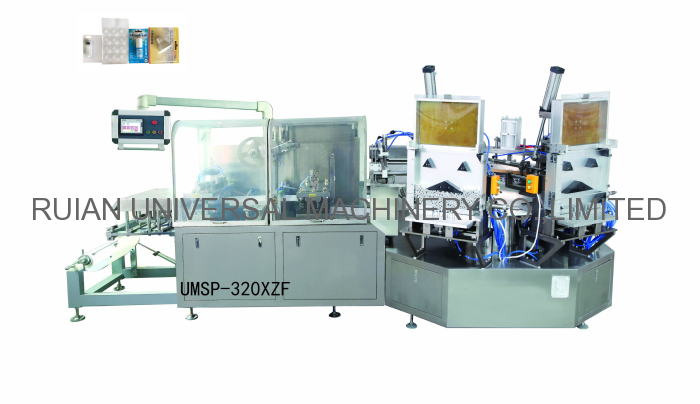

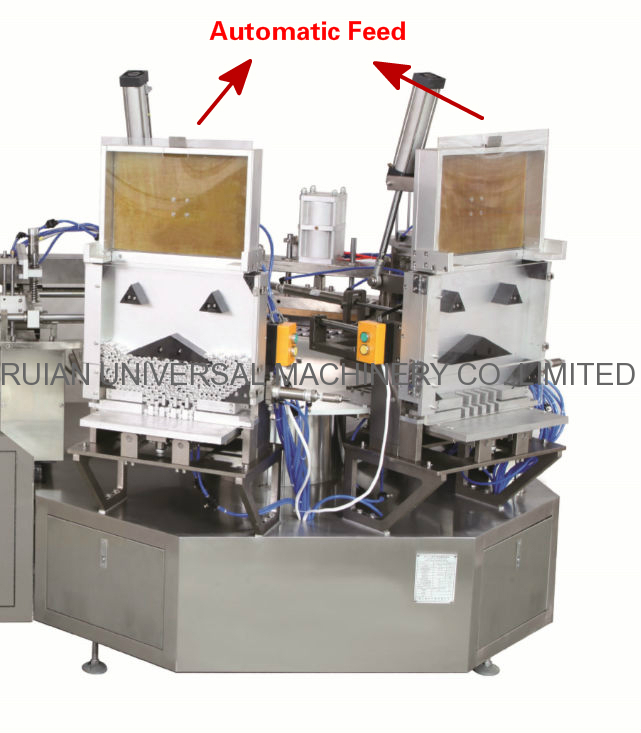

Automatic Electronic Product Flashlight PVC Cardboard Blister Packing Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100 sets/year |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Wenzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | UMSP-320XZF |

|---|---|

| Means of Transport: | Ocean, Land |

| Processing: | Blister Packaging Machine |

| Packaging: | Plastic |

| Automatic Grade: | Automatic |

| Type: | General |

| Usage: | Outer |

| Brand Name: | UNIMAC |

| Overall Dimensions: | 3650*2500*1850mm(L*W*H) |

| Cutting Frequency: | 10-25 times/min |

| Adjustable Travel Range: | 35-160mm |

| Max. Forming Area: | 340*160mm |

| Total Power: | 380V 50Hz (480V 50Hz) 10KW |

| Production Capacity: | 100 sets/year |

| Packing: | wooden case |

| Delivery Date: | 20 working days |

Product Description

Model: | UMSP-320XZF |

Cutting Frequency | 10-25 times/min |

Adjustable Travel Range | 35-160mm |

Max. Forming Area | 340*160mm |

Max. Forming Depth | 38mm (Special Machine 50mm) |

Forming and Heating Power(Upper and Down) | 1.8KW (x 2) |

Sealing and Heating Power | 3.5KW |

Total Power | 380V 50Hz (480V 50Hz) 10KW |

Main Motor Power | 1.5KW |

Air Pump Volume Flow | ≥0.6m³/min |

Packing Material: Roll | ≤400(Diameter)*350(Width)*0.2-0.5mm(Thickness) |

Packing Material: Paperboard | ≤350*200*0.5mm(L*W*H) |

Overall Dimensions | 3650*2500*1850mm(L*W*H) |

Weight | 1800Kg |

This machine is especially fitting for companies which with low production capacity but need various products and acquires changing molds frequently.

It is a full automatic plastic cardboard blister packing machine, suitable for packing various kinds of products, such as medical injection, injection syringe,

toy car,, electronic torch, sparking plug, toothbrush, lipstick, mask, chopstick, shaver, scissor, hook, cleaning ball, bottle opener, correction fluid, ball-point pen,

pencil, pencil sharpener and so on.

1. The assembly line consists of blister molding and rotating heat-sealing.

2. The positive/negative pressure molding, precise forming, make the product more beautiful.

3. Full automatic helps save labor work and material.

4. It uses servo motor drive steplessly and is easy to operate.

5. The separate-type design makes it convenient to transport and is free out of the elevator.

6. Full humanity with low noise.

7. It's very easy to change the molds, thus improving the production efficiency.

8. Molds can be designed according to special needs and auto-feeding device is alternative.

Smaple Show