Holmbury MP Series Interchangeable Hydraulic Muliti-Coupling 4 Ports 1/2 3/8 Inch

| Min. Order: | 10 Pair |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | Paypal, L/C, T/T, WU |

| Supply Ability: | 100000 |

| Place of Origin: | Shanghai |

Company Profile

| Location: | Shanghai, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | DL |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Head Code: | Hexagon |

| Shape: | Equal |

| Technics: | Forged |

| Type: | Coupling |

| Material: | Carbon Steel |

| Connection: | Female |

| Brand Name: | Century |

| Size: | 3/8-1/2 |

| Thread: | BSP |

| Usage: | Truck |

| Fluid Type: | Hydraulic Oil |

| Pressure: | 31.5Mpa |

| Color: | Grey |

| Surface treatment: | Zinc |

| Standard: | Multifaster |

| Interchangeable: | Faster |

| Production Capacity: | 100000 |

| Packing: | Carton |

| Delivery Date: | 30 days |

Product Description

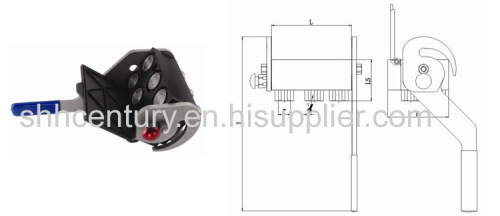

DL/DLD have a compact structure, manual multi-couplings that offer a wide range of solutions for any application requiring connection and disconnection of several hydraulic. Up to 6 lines can be simultaneously connected and disconnected by a safe, simple and quick movement requiring low effort. The lines can all have the same size or each line can be different from the others according to the application.

TECHNICAL FEATURES AND OPTIONS

Interchangeability: Internal Standard

Mechanical connection: Internal cams and locking pins

Connection system: Rotating the lever

Disconnection system: Rotating the lever

Construction material and surface treatment:

Body plates in aluminum alloy oxidation

Cams and pins in high resistance carbon steel with special heat treatment.

Others components in carbon steel with zinc plating or zinc nickel treatment

HOW TO USE

TO CONNECT:

Before to couple clean the flat mating surface of the couplings to avoid the inclusion of dirty in the circuit.

Insert the guidance pins of the mobile multicoupling

in the holes of the fixed multicoupling and move the mobile half till the contact of the couplings faces (fig. 1).

Acting on the handle turn the lever in the direction of the fixed multicoupling (fig. 2).

Continue to rotate till the safety lock automatically engage itself (fig. 3).

Now the multicoupling is coupled and ready to work. In case of connection with residual pressure in the circuit , the maximum force is required only for the last third of the connection.

TO DISCONNECT

Push the red safety button, at the same time acting on the handle turn the lever in the direction of the mobile multicoupling (fig. 4).

Continue to rotate till the mechanical stop of the levers (fig. 5)

Now the multicoupling is uncoupled and it is possible to pull out the mobile half (fig. 6).

When the fixed multicoupling is mounted upside down, the mobile multicoupling must be supported in order to avoid it fall down causing damage.

In case of disconnection with residual pressure in the circuit, the maximum force is required only for the first third of the disconnection.

Body Size(in) | 3/8 | 1/2 |

Rated Pressure (PSI) | 4350 | 4350 |

Rated Flow(GPM) | 6 | 12 |

Temperature Range(std seals) | -20℃ to +120℃ | |

Standard seal material | NBR | |

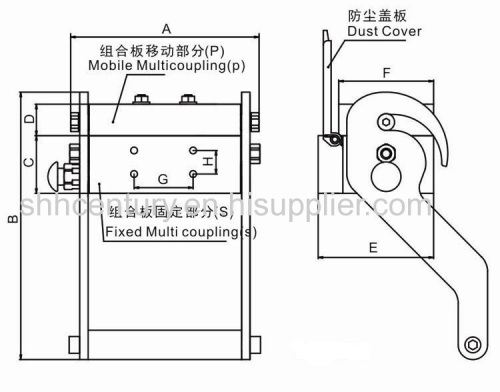

SIZE | PARTNO. | A | B | C | D | E | F | G | H |

6*12(12.5) | DL6-04 | 179.5 | 255 | 55 | 30 | 110 | 90.4 | 50 | 30 |

4*12(12.5) | DL4-04 | 135.3 | 255 | 55 | 30 | 110 | 90.4 | 50 | 30 |

2*12(12.5) | DL2-04 | 123 | 255 | 55 | 30 | 110 | 90.4 | 47.3 | 30 |

6*3/8(10) | DL6-03 | 160.5 | 255 | 50 | 25 | 110 | 86.5 | 84.8 | 28 |

4*3/8(10) | DL4-03 | 123 | 255 | 50 | 25 | 110 | 88.5 | 47.3 | 28 |

2*3/8(10) | DL2-03 | 123 | 255 | 50 | 25 | 110 | 88.5 | 47.3 | 28 |

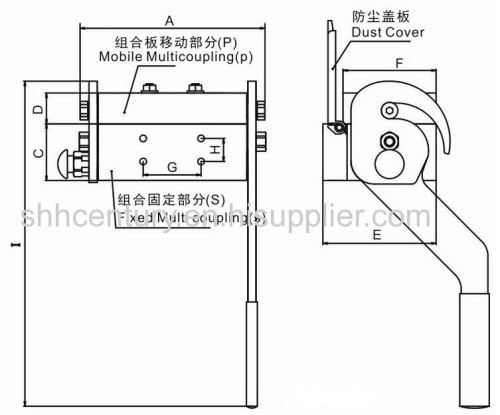

SIZE | PARTNO. | A | B | C | D | E | F | G | H |

6*12(12.5) | DLD6-04 | 179.5 | 314 | 55 | 30 | 110 | 90.4 | 50 | 30 |

4*12(12.5) | DLD4-04 | 135.3 | 314 | 55 | 30 | 110 | 90.4 | 50 | 30 |

2*12(12.5) | DLD2-04 | 123 | 314.5 | 55 | 30 | 110 | 90.4 | 47.3 | 30 |

6*3/8(10) | DLD6-03 | 160.5 | 314.5 | 50 | 25 | 110 | 86.5 | 84.8 | 28 |

4*3/8(10) | DLD4-03 | 123 | 314.5 | 50 | 25 | 110 | 88.5 | 47.3 | 28 |

2*3/8(10) | DLD2-03 | 123 | 314.5 | 50 | 25 | 110 | 88.5 | 47.3 | 28 |

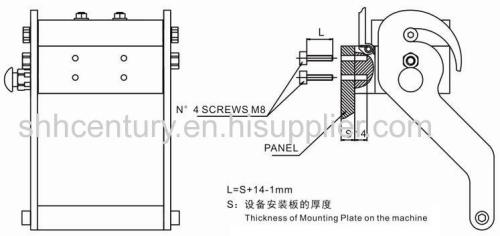

INSTALLATION:

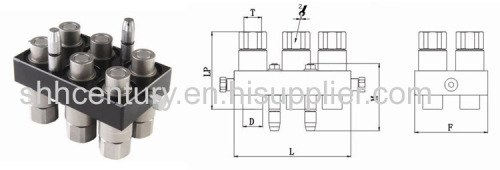

Fix the fixed multicoupling on the machine using fixing screws as indicated in the drawing here below.

SIZE | PARTNO. | T | HEX1 | L | LS | B | E |

6*12(12.5) | DL6-04 | G1/2 | S32 | 144.5 | 74.9 | 255 | 110 |

4*12(12.5) | DL4-04 | G1/2 | S32 | 100.3 | 74.9 | 255 | 110 |

2*12(12.5) | DL2-04 | G1/2 | S32 | 88 | 74.9 | 255 | 110 |

6*3/8(10) | DL6-03 | G3/8 | S24 | 125.5 | 68 | 255 | 110 |

4*3/8(10) | DL4-03 | G3/8 | S24 | 88 | 68 | 255 | 110 |

2*3/8(10) | DL2-03 | G3/8 | S24 | 88 | 68 | 255 | 110 |

SIZE | PARTNO. | T | HEX1 | L | LS | I | E |

6*12(12.5) | DLD6-04 | G1/2 | S32 | 144.5 | 74.9 | 314.5 | 110 |

4*12(12.5) | DLD4-04 | G1/2 | S32 | 100.3 | 74.9 | 314.5 | 110 |

2*12(12.5) | DLD2-04 | G1/2 | S32 | 88 | 74.9 | 314.5 | 110 |

6*3/8(10) | DLD6-03 | G3/8 | S24 | 125.5 | 68 | 314.5 | 110 |

4*3/8(10) | DLD4-03 | G3/8 | S24 | 88 | 68 | 314.5 | 110 |

2*3/8(10) | DLD2-03 | G3/8 | S24 | 88 | 68 | 314.5 | 110 |

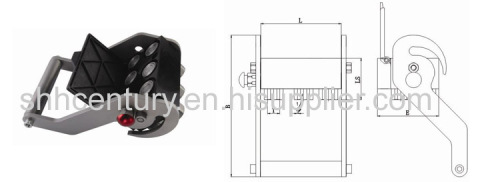

SIZE | PARTNO. | T | HEX2 | L | LP | M | F | D | |

6*12(12.5) | DL6-04 | G1/2 | S32 | 144.5 | 95.8 | 83 | 90.4 | 24.54 | |

4*12(12.5) | DL4-04 | G1/2 | S32 | 100.3 | 95.8 | 83 | 90.4 | 24.54 | |

2*12(12.5) | DL2-04 | G1/2 | S32 | 88 | 95.8 | 83 | 90.4 | 24.54 | |

6*3/8(10) | DL6-03 | G3/8 | S24 | 125.5 | 78 | 83 | 86.5 | 19.75 | |

4*3/8(10) | DL4-03 | G3/8 | S24 | 88 | 78 | 83 | 86.5 | 19.75 | |

2*3/8(10) | DL2-03 | G3/8 | S24 | 88 | 78 | 83 | 86.5 | 19.75 | |

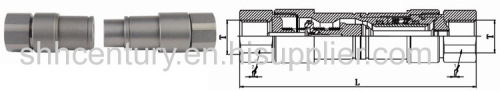

SIZE | PARTNO. | T | HEX1 | HEX2 | L |

12.5 | DL-04 | G1/2 | S32 | S32 | 153 |

10 | DL-03 | G3/8 | S24 | S24 | 130.5 |

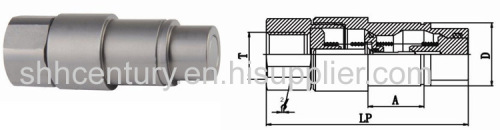

SIZE | PARTNO. | T | HEX1 | LP | D | A |

12.5 | DL-04PF | G1/2 | S32 | 95.8 | 30 | 26.6 |

10 | DL-03PF | G3/8 | S24 | 78 | 24 | 23.2 |

SIZE | PARTNO. | T | HEX1 | LS | D | A |

12.5 | DL-04SF | G1/2 | S32 | 74.9 | 30 | 26.6 |

10 | DL-03SF | G3/8 | S24 | 68 | 24 | 19.8 |