Carbon Steel Flat Face Hydraulic Quick Coupling NPT 1/2'' Quick Coupler Set

| Min. Order: | 100 Pair |

|---|---|

| Trade Term: | FOB,CIF,EXW |

| Payment Terms: | Paypal, L/C, T/T, WU |

| Supply Ability: | 100000 |

| Place of Origin: | Shanghai |

Company Profile

| Location: | Shanghai, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | CT-FF |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Head Code: | Hexagon |

| Shape: | Equal |

| Technics: | Forged |

| Type: | Coupling |

| Material: | Carbon Steel |

| Connection: | Female |

| Brand Name: | Century |

| Technics: | CNC Machine |

| Pressure: | 31.5Mpa |

| COLOR: | Silver |

| Application: | Machinery |

| Standard: | ISO16028 |

| Product name: | Flat Face Quick Coupling |

| Size: | 1/4-2'' |

| Thread: | NPT BSP BSPT |

| Surface Treatment: | Zinc |

| Usage: | Industrial |

| Production Capacity: | 100000 |

| Packing: | Carton |

| Delivery Date: | 30 days |

Product Description

CT-FF Series couplings are widely used in the public utility market where hydraulic oil spillage can constitute a serious safety hazard, particularly in overhead bucket hoists that are used for maintenance of high-voltage power transmission lines.These couplings are also used for quick change of hydraulic Tools in construction, railway maintenance and mining industries. The ease of cleaning makes them ideal for use in these types of hostile environments.

Body Size(in) | 1/4(02) | 3/8(03) | 1/2(04) | 5/8(06) | 3/4(08) | 1(10) | 1-1/2(12) | 2(16) |

Rated Pressure(PSI) | 5000 | 4350 | 4350

| 3625 | 3625 | 3000 | 3000 | 3000 |

Rated Flow(GPM) | 3 | 6 | 12 | 20 | 28 | 50 | 80 | 100 |

Spillage (ML) | 0.006 | 0.012 | 0.02 | 0.026 | 0.032 | 0.035 | 0.05 | 0.1 |

(max. per disconnect) | ||||||||

Temperature Range | -20℃ to +120℃ | |||||||

Standard seal material NBR | ||||||||

New valve design. it can resistance damage from high flow and the pressure of impulse that providing advanced performance.

Sleeve locking mechanism is engaged by rotating sleeve after connection. It prevents accidental disconnection when the coupling is dragged along the ground.

Sleeve mechanism is designed to prevent dirt from entering the internal mechanism and thus causing faulty operation when connecting or disconnecting. The sleeve covers the retaining ring and also incorporates a dust seal in the spring area.

Steel construction, zinc plated with yellow chromate finish. hardened nipples and sleeves and solid barstock construction for maximum resistance to damage from hydraulic and mechanical shock.

This Anti –Blowout Nitrile/PTFE bonded seal is designed to prevent blow-out or damage during severe service conditions.

Durable ball-locking mechanism assures reliable connections every time. A large number of locking balls distributes the work load evenly while providing alignment and swiveling action to reduce hose torque and prolong hose life. CAUTION: These products are not not to be used as swivels. Rotation under pressure will result in excessive and premature wear.

CT-FF Series couplings employ flush valving when connecting or disconnecting. This means that the valves are mated together so that only small amounts of fluid can be lost during disconnection or air inclusion during reconnection.

New chrome plating treatment provides advanced anti-rust performance.

CT-FF series conforms to standard of ISO16028.

Compatible with PARKER FEM Series,STUCCHI FIRG Series, AEROQUIP FD89 Series and HANSEN FF Series.

ISO | PART NO | LS | D | HEX1 | A | T |

6.3 | CT-FF-02SF | 58.2 | 28 | 20 | 14 | G1/4 NPT1/4 |

10 | CT-FF-03SF | 68.2 | 32 | 24 | 14 | G3/8 NPT3/8 |

10 | CT-FF-03SF | 72.2 | 32 | 27 | 18 | G1/2 NPT1/2 |

12.5 | CT-FF-04SF | 75 | 38 | 32 | 18 | G1/2 NPT1/2 |

12.5 | CT-FF-04SF | 79 | 38 | 36 | 22 | G3/4 NPT3/4 |

16 | CT-FF-06SF | 80 | 42 | 36 | 22 | G3/4 NPT3/4 |

19 | CT-FF-08SF | 99.8 | 48 | 41 | 22 | G3/4 NPT3/4 |

19 | CT-FF-08SF | 99.8 | 48 | 41 | 23.5 | G1 NPT1 |

25 | CT-FF-10SF | 111.5 | 56 | 55 | 24 | G1-1/4 NPT1-1/4 |

- | CT-FF-12SF | 150 | 79.5 | 65 | 30 | G1-1/2 NPT1-1/2 |

- | CT-FF-16SF | 167 | 98.5 | 85 | 31 | G2 NPT2 |

ISO | PART NO | LP | d | C | HEX2 | A | T |

6.3 | CT-FF-02PF | 49.2 | 16.1 | 15.2 | 20 | 14 | G1/4 NPT1/4 |

10 | CT-FF-03PF | 55.8 | 19.7 | 19.5 | 24 | 14 | G3/8 NPT3/8 |

10 | CT-FF-03PF | 59.8 | 19.7 | 19.5 | 27 | 18 | G1/2 NPT1/2 |

12.5 | CT-FF-04PF | 72 | 24.5 | 21.6 | 32 | 18 | G1/2 NPT1/2 |

12.5 | CT-FF-04PF | 76 | 24.5 | 21.6 | 36 | 22 | G3/4 NPT3/4 |

16 | CT-FF-06PF | 75.5 | 27 | 21.6 | 36 | 22 | G3/4 NPT3/4 |

19 | CT-FF-08PF | 93.8 | 30 | 29 | 41 | 22 | G3/4 NPT3/4 |

19 | CT-FF-08PF | 93.8 | 30 | 29 | 41 | 23.5 | G1 NPT1 |

25 | CT-FF-10PF | 90 | 36 | 34 | 55 | 24 | G1-1/4 NPT1-1/4 |

- | CT-FF-12PF | 112 | 57 | 38 | 65 | 30 | G1-1/2 NPT1-1/2 |

- | CT-FF-16PF | 123.9 | 73 | 40.5 | 75 | 31 | G2 NPT2 |

ISO | PART NO | L | D | HEX1 | HEX2 | T |

6.3 | CT-FF-02 | 96.2 | 28 | 20 | 20 | G1/4 NPT1/4 |

10 | CT-FF-03 | 108.4 | 32 | 24 | 24 | G3/8 NPT3/8 |

10 | CT-FF-03 | 116.4 | 32 | 27 | 27 | G1/2 NPT1/2 |

12.5 | CT-FF-04 | 129.3 | 38 | 32 | 32 | G1/2 NPT1/2 |

12.5 | CT-FF-04 | 137.3 | 38 | 36 | 36 | G3/4 NPT3/4 |

16 | CT-FF-06 | 138 | 42 | 36 | 36 | G3/4 NPT3/4 |

19 | CT-FF-08 | 172.1 | 48 | 41 | 41 | G3/4 NPT3/4 |

19 | CT-FF-08 | 172.1 | 48 | 41 | 41 | G1 NPT1 |

25 | CT-FF-10 | 178 | 56 | 55 | 55 | G1-1/4 NPT1-1/4 |

- | CT-FF-12 | 233.4 | 79.5 | 65 | 65 | G1-1/2 NPT1-1/2 |

- | CT-FF-16 | 251.7 | 98.5 | 85 | 75 | G2 NPT2 |

Workshop:

Warehouse:

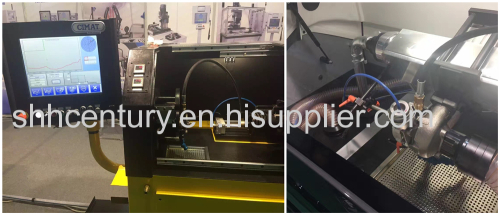

Test Machine:

Showroom:

More Applications: