Wholesale press brake V die and punch tools

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,DAP,CIP,CPT,FCA |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU |

| Supply Ability: | about 400 set/month |

| Place of Origin: | Anhui |

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | press brake dies |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | DURMAPRESS |

| Hardness: | 42-48HRC |

| Sharpness: | 18-30N |

| Precision: | +-0.005mm |

| material: | 42CrMo |

| Packaging: | wooden case |

| Application: | Used for Press Brake |

| Size: | Customer Size Accepted |

| another use: | Cold-rolling mill plant |

| Warranty: | 5 Years |

| Production Capacity: | about 400 set/month |

| Packing: | Wooden package of the both angle notcher |

| Delivery Date: | 30 days |

Product Description

Mananshan Durmapress Machinery Technology Co., Ltd >>>

Our company founded in 1990s is a fixed-point company of Ministry of Construction of China, we are engaging in construction machinery researching, development and manufacturing. Our main products are JZM series electric rolling drum concrete mixers, JS Series Double shaft concrete

mixer,JZR series diesel engine concrete mixers, PLD series aggregate batching and dispensing machines, LSY series cement screw conveyors and HZS/HLS series concrete mixing and batching plant. All these products have won great favor and popularity with more and more customers in

domestic and oversea markets.

| Material | 42CrMo=SCM440=42CrMo4=4140 |

| General Hardness | 47+/-2HRC |

| Surface Tolerance | 0.02mm |

| Sectioned | AVAILABLE |

| Certification | ISO9001:2008 |

| Supplying Brands | amada, tokyo, trumpf, LVD, YSD, beyeler, etc. |

| OEM & ODM Service | available |

| CUSTOMIZE & DESIGN Service | available |

| Tool Refurbishment Service | available

|

Product Name | Bending machine press brake tool |

Material | 42CrMo or SKD-11. |

Hardness | 45-49 HRC. |

Maximum length | 12m. |

Sample | Available,charges depend on different types. |

Sample Time | Within 5-7 working days. |

Application | Used for bending machine. |

OEM and ODM | Acceptable. |

Delivery Time | Within 15 days after receiving down payment. |

Payment Terms | By L/C,D/A,D/P,T/T,Western Union,MoneyGram |

Product description

1. Fourteen years experience

2. We have our own mold-making workshops.

3. We make steel by ourselves, so the materials are various

4. Forging steel make the inside microstructure become much closer and the metal grain size becomes mch smaller to ensure a long worklife.

5. Competitive price

6. Passed the ISO9001 quality certification in 2001

7. OEM and ODM

8. Specializes in manufacturing all kinds of industrial cutting tools, including press brake tooling, metal shearing blade, progress stamping dies, hydraulic deep drawings, slitting knives, shearing blades, paper cutting, rubber cutting knife, ink knife, wear-resistant furnace sliders, tungsten inlaid blades, rollers, etc

9. Blade: Maximum length of 5500mm and maximum diameter of 1500mm

10. Materials5CrW2Si, 6CrW2Si, Cr12MOV, 9CrSi, H13 and self-developed H13k, HMB and HMK high various alloy steel

11. High intensity, high hardness, high toughness, and high Durability, etc.

12. Widely used in industries of steel, rubber, paper making, and so on.

13. Each technical index reaches the international standard.

Packaging & shippingPackaging Detail: standard exporting package or depend on customers' demand1. packaged in plasticfilm.2. pallet or wood box.3. ground fixed bolt to confirm steady and avoid destory.4. tightly exporting standard belf to fasten machine in container.Delivry Detail: Within 30 days after receive deposit

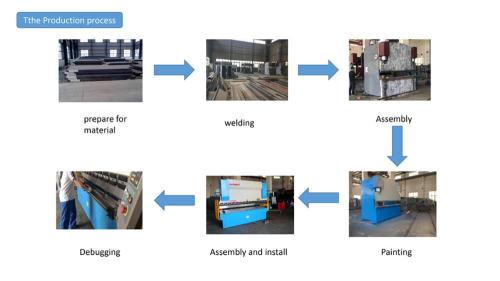

Operatinal Progress:

Steel-making— Blanking— Forging Steel— Rough Progressing— Heat Treatment— Finishing— Testing

We manufacture industrial knives up to 6500mm(255.905 inches) in length for cutting sheet steel etc.

Steel-making by medium frequency furnaces

Steel-making by medium frequency furnacesSteel-making begins from the start of this century in WILACNC Company. So the company can meet special requirements for materials. In order to guarantee the quality, WILACNC company imported spectrometer from Germany and is equipped with various tester, such as tensile tester, impact testing machine, metallography analyzer and so on.

Electro slag remelting

The largest ingot can reach 3 tons in WILACNC company. The ingot obtained by this remelting/refining process is very homogeneous and free of internal defects. The segregation of the ingot(called macro-segregations) are substantially eliminated and the segregations of crystals(called micro-segregations)are significantly reduced. The ESR remelted material improve following mechanical characteristics:

. Improved toughness due to increased homogeneity and isotropy

. Improved creep resistance properties

. Best fatigue strength and tenacity properties as well as outstanding tensile strength

. Improved purity

Forging steel

Forging process can trance to 1990s in WILACNC company. The largest electro-hydraulic hammer is 4.5 ton. And more than 6 skilled technicians work here. After forging the inside microstructure becomes much closer and the metal grain size becomes much smaller. It can elevate the characteristics and quality of the knife ensuring a longer life of the knife.

Rough processing

No less than 40 sets of processing equipment in the rough processing workshop of WILACNC company, including lathe, milling machine, planer, drill machine etc. Skilled workers are employed in its rough processing workshop.

Finishing processing

durmapress company has more than 35 sets of processing equipment including internal grinder, external grinder, surface grinder, CNC grinder, electric spark CNC wire-cut etc. The company can produce the shearing blades with 5800mm in length and slitting knives with 1400mm in outside diameter.

Testing

Various testers are put to use for testing its products in our laboratory. They are including tensile tester impact testing machine, metallography analyzer, harmless flaw detector, magnetic powder inspection, hardness tester, caliper rule, microcalliper, etc. Testing is carried out after each step. And every products has a unique tracking number. Thus it is easy to trace back anytime

Our service:

| 5. Maintenance after sale |

| 1. This product's warranty period is one year. |

| 2. If users modify machine without permission of our technology department, and get the machine damaged, we are not responsible to maintain the machine for free. |

| 3. In the warranty period, if the machine get damaged because users operate it improperly, materials expenses will be required. |

| 4. After warranty period, we will continue to offer technical assistance. |

Package & shipping

6. Packaging and shippingPackaging Detail: standard exporting package or depend on customers' demand.1 packaged in plasticfilm.2 pallet or wood box.3 ground fixed bolt to confirm steady and avoid damage.4 tightly belf to fasten machine in container.Delivry Detail: normally within 30 days after receive deposit.

Price: Give me reply, i will give you my favorable price immediately!

Payment term: 30% deposit and the balance paid against copy of B/L in 3 days.

Package: Standard exporting package.

Operation manual and video disc:

When delivery machine, the related operation instruction of model will delivery together with machine. And in the instruction, there is teaching video disc.

After-sales service:

1.machine is simple, generally, user can understand how to operate. There is operation instruction and disc.

2.welcome to our factory to learn how to operate our machine, we will give good training.

3.our engineer is available for user. If there is requirement, our engineer can go to user factory, and adjust machine, give good training to user.