100T2500 iron bending machine press brake tooling amada

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | Paypal, D/P, D/A, T/T, WU |

| Supply Ability: | about 400 set/month |

| Place of Origin: | Anhui |

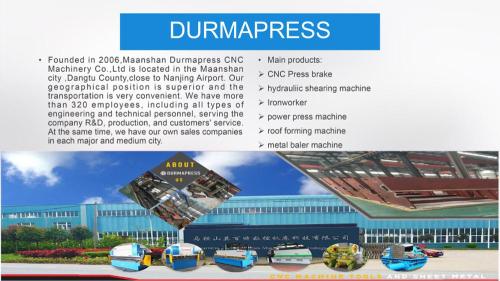

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | WC67Y/K-100/2500 |

|---|---|

| Means of Transport: | Ocean, Land |

| Power: | Hydraulic |

| Raw Material: | Sheet / Plate Rolling |

| Machine Type: | Press Brake |

| Extra Services: | End Forming |

| Automation: | Automatic |

| Certification: | CE |

| Material / Metal Processed: | Stainless Steel |

| Brand Name: | durmapress |

| Norminal Pressure: | 1000KN |

| Worktable Length: | 2500mm |

| Poles distance: | 1970mm |

| Throat depth: | 250mm |

| Stroke: | 100mm |

| Open height: | 320mm |

| Power: | 5.5kw |

| Dimension: | 3200x1600x2200 |

| Main motor: | Siemens from Germany |

| Hydraulic system: | Bosch-Rexroth from Germany |

| Production Capacity: | about 400 set/month |

| Packing: | Wooden package of the both angle notcher |

| Delivery Date: | 30 days |

Product Description

Established in 2001, Jiangyin Metallurgy Hydraulic Machinery Factory is located in Jiangyin, an economic leading city in eastern China. As a professional manufacturer of hydraulic machineries, our company integrates with capabilities of design, research, development and production.

After 25 years of rapid development, we have become a well-known factory in domestic metal scrap recycling industry. Our products metal baler are widely applied to the industries of metal recycling, foundry and metallurgy and are well received. Currently, we have two plants, the machining plant and the assembling plant, cover an area of 12000 square meters. There are more than 150 staff members, 17 professionals among them. And we have obtained 12 national patents so far.

Our main products are as follows, namely, hydraulic briquetting press, hydraulic metal baler and hydraulic alligator shear. Our products are not only popular in China, but also have market shares in more than 20 Countries, for example, India, Russia, Ukraine, Japan, Thailand, Kuwait, Vietnam, Indonesia, Canada and Columbia.

For the sake of the benefits of our new and old customers, we will ceaselessly improve the product quality as much as we can.

Our factory was awarded the quality control approval certificate ISO9001, from material test, process inspection to final test complete quality control system is already in place.

hydraulic steel stainless sheet metal bending machine sheet bender folding machine folder pan brake machinery

Standard Features

| 1. Hydraulic clamp and unclamp from foot switch, this allows one man to operate machine and hold material in both hands; Clamping is limited to 10mm increments for safety. Unclamp from foot switch. |

| 2. Rapid head adjustment allows easy change different size material, by moving the handles, Adjustable to suit special jobs . |

| 3. Fingers clamp blade are high carbon steel, Apron blade high tensile steel. |

| 4. Electrics low 24 volts foot switch. Overload protected. |

| 5. Clamping provided by large rams, Oil delivered to rams through steel pipes this is to minimize expansion of hydraulic hose when working at full capacity. |

| 6. Unclamp is controlled, to allow the operator to regulate the open height |

| 7. Bed head and apron are unique design, to provide maximum strength. To give a straight fold. |

| 8. Automatic and manual control. In auto cycle after clamping start auto a[rpm will come up to angle set, then apron will go down and the head will unclamp to amount set by operator. |

| 9. Electric components is.SIEMENS |

Specifications

| Monolithic steel-welded construction |

| Hydraulic system drive, |

| CNC system,high precision. Easy to operate Function and characteristic: The machine tool is full welded-steel plate construction. After vibration aging treatment, the deformation is minor so that the accuracy can be ensured. Machine is hydraulically powered. It is low energy construction, easy to maintenance and durable in use. Upper acting die is sub-portfolio with the open height up to 110mm and suitable for producing disk, box like workpieces. The bending angle and back gauge is controlled by numerical control system, rapidly and accurately |

Using a combination of blowing and automatic folding kinfe technology. Adopting large-screen liquid crystal display intelligent control system.The use of teo-wheeled two-speed system,regardless of the size of the comptroller line setting a precise folding. The running speed adjustment range,can be matched with a variety of ironing machine.With self-diagnostic function,single-link signal detectiontechniques and improve the safety protection system.The control computer by realy output port without intermediate realy accurate and easy maintenance.With automatic elimination of static switching devices and safety protection. |

Technical Training

Tenroy company is responsible for the user operator training and also we will provide a training software to you.

Quality Assurance

Our company is responsible for the maintenance during the use period (damage that caused by improper operation, the user should bear the repair charge). Warranty is 12 months after the end debugging.