ESA system stainless steel bending machine large press brake

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,DDP,DAP,CPT,FCA |

| Payment Terms: | Paypal, D/P, D/A, T/T, WU |

| Supply Ability: | about 400 set/month |

| Place of Origin: | Anhui |

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | WC67Y/K-160T3200 |

|---|---|

| Means of Transport: | Ocean, Land |

| Power: | Hydraulic |

| Raw Material: | Sheet / Plate Rolling |

| Machine Type: | Press Brake |

| Extra Services: | End Forming |

| Automation: | Automatic |

| Certification: | CE |

| Material / Metal Processed: | Stainless Steel |

| Brand Name: | durmapress |

| Norminal Pressure: | 1600KN |

| Worktable Length: | 3200mm |

| Poles distance: | 2510mm |

| Throat depth: | 320mm |

| Stroke: | 200mm |

| Open height: | 450mm |

| Power: | 11kw |

| Dimension: | 3200x1900x2700 |

| Main motor: | Siemens from Germany |

| Hydraulic system: | Bosch-Rexroth from Germany |

| Production Capacity: | about 400 set/month |

| Packing: | Wooden package of the both angle notcher |

| Delivery Date: | 30 days |

Product Description

Mananshan Durmapress Machinery Technology Co., Ltd >>>

Our company founded in 1990s is a fixed-point company of Ministry of Construction of China, we are engaging in construction machinery researching, development and manufacturing. Our main products are JZM series electric rolling drum concrete mixers, JS Series Double shaft concrete

mixer,JZR series diesel engine concrete mixers, PLD series aggregate batching and dispensing machines, LSY series cement screw conveyors and HZS/HLS series concrete mixing and batching plant. All these products have won great favor and popularity with more and more customers in

domestic and oversea markets.

Our Advantages:

curtain track bending machine

1. Overal welding structure

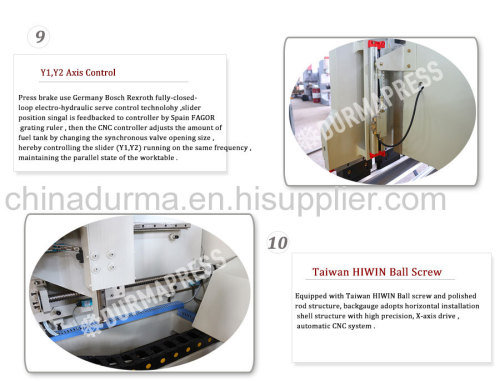

2. Closed loop control mode formed by Gemany electro-hydraulic servo valve and import grating ruler. The slider position have high precision feedback, stable operation, good synchronization performance, high precision of bending and slider repeat positioning.

3. Back gauge can use multi back gauge axis with more function according to customer requirements..

4. Hydraulic system uses integrated control system which can reduce pipeline installation, overcome the leakage and ensure the stability of machine operation. And it has a simple and beautiful appearance also.

5. The automatic compensation mechanism of Hydraulic defection has eliminated the effect of the slider deformation on the workpiece quality. The numeric control system adjusts the compensation amount automatically which is convenient and accurate.

6. The numeric control system adopts the special CNC system of Electrohydraulic Servo Numeric-control bending machine from Holland DELEM, Italy ESA or Switzerland CYBELEC.

Equipped with special controller with automatic test and self-diagnosis.

Programming a product simply consists of introducing the characteristics of the material to be bent,the dimensions of the product and the necessary tooling & die.The optimizing software searches for the best bending cycle.

Ram stroke(Y1,Y2) and backgauge(X,R,Z) are controlled by controller automatically,high productivity.

Adopting Electro-hydraulic proportional servo synchronization.Optional point within stroke can be controlled.Repeat precision of Y axes:±0.01mm,Parallism:0.02mm.Strong ability of deviation resistance.

Backgauge adopts ball-bearing screw and rolling guideway,quick speed and high repeat positioning precision.X axes with resolution 0.1mm.

Imports including linear transducer,pressure proportional valve and servo motor.

The models are available in variety of tounge from 40 ton up to 1000 ton and length from 2000 mm up to 8000 mm.The specifications below 300 ton refer to Series WC67Y.Any tailor-made are available on request.

Description

Color | Any color is available |

Logo | Customized Logo for Best-selling bending machine |

MOQ | Small MOQ,1 SET for Best-selling bending machine |

Delivery Time | (1) 30-60 days –If you want to customize your request. (2)25 days – For our Standard. |

| OEM Accepted | Yes |

| Certification available | Yes |

CNC System | Delem . ESTON ^ |

| Packing Details | 20GP ,40GP ,20 OT Or LCL |

Production Capacity | 500/sets Best-selling bending machine Per Month. |

Payment Term | L/C ,T/T,D/A,WEST UNION,MONEY GRAM. |

| Model | Nominal force | Length of table | Distance ofcolumn | Depth of throat(mm) | Ram stroke(mm) | strokes | Open height | Main power | Overall dimensions |

| 30/1600 | 300 | 1600 | 1200 | 200 | 100 | ≥11 | 310 | 3 | 1500×1181×1886 |

| 40/2000 | 400 | 2000 | 1650 | 200 | 100 | ≥11 | 340 | 4 | 2300×1500×2060 |

| 63/2500 | 630 | 2500 | 2050 | 250 | 100 | ≥10 | 335 | 5.5 | 2800×1725×2190 |

| 63/3200 | 630 | 3200 | 2670 | 250 | 100 | ≥10 | 335 | 5.5 | 3450×1725×2405 |

| 80/2500 | 800 | 2500 | 2060 | 250 | 100 | ≥10 | 350 | 7.5 | 2750×1795×2405 |

| 80/3200 | 800 | 3200 | 2660 | 250 | 100 | ≥10 | 350 | 7.5 | 3450×1810×2420 |

| 80/4000 | 800 | 4000 | 3110 | 250 | 100 | 10 | 350 | 7.5 | 4250×1820×2600 |

| 100/2500 | 1000 | 2500 | 2050 | 320 | 100 | ≥8 | 365 | 7.5 | 2900×1800×2415 |

| 100/3200 | 1000 | 3200 | 2650 | 320 | 100 | ≥8 | 415 | 7.5 | 3500×1800×2540 |

| 100/4000 | 1000 | 4000 | 3100 | 320 | 100 | ≥8 | 415 | 7.5 | 4120×1800×2765 |

| 125/3200 | 1250 | 3200 | 2650 | 320 | 150 | ≥8 | 415 | 7.5 | 3500×1910×2635 |

| 125/4000 | 1250 | 4000 | 3200 | 320 | 150 | ≥8 | 415 | 7.5 | 4090×1875×2825 |

| 160/3200 | 1600 | 2640 | 2800 | 320 | 200 | ≥6 | 480 | 11 | 34500×2060×2660 |

| 160/4000 | 1600 | 4000 | 3100 | 320 | 200 | ≥6 | 480 | 11 | 4280×2060×2640 |

| 160/5000 | 1600 | 5000 | 4030 | 320 | 200 | ≥6 | 470 | 11 | 5250×2150×2820 |

| 200/3200 | 2000 | 3200 | 2650 | 320 | 200 | ≥3 | 560 | 15 | 3280×2200×2520 |

| 200/4000 | 2000 | 4000 | 3100 | 320 | 200 | ≥3 | 560 | 15 | 4280×2200×2800 |

| 250/3200 | 2500 | 3200 | 2620 | 400 | 250 | ≥3 | 560 | 15 | 3280×2200×2900 |

| 250/4000 | 2500 | 4000 | 3300 | 400 | 250 | ≥3 | 560 | 15 | 4080×2200×3060 |

| 300/4000 | 3000 | 4000 | 3000 | 400 | 250 | ≥3 | 560 | 22 | 4080×2260×3150 |

| 300/6000 | 3000 | 6000 | 3000 | 400 | 250 | ≥3 | 560 | 22 | 6080×2260×3350 |

Our service:

| 5. Maintenance after sale |

| 1. This product's warranty period is one year. |

| 2. If users modify machine without permission of our technology department, and get the machine damaged, we are not responsible to maintain the machine for free. |

| 3. In the warranty period, if the machine get damaged because users operate it improperly, materials expenses will be required. |

| 4. After warranty period, we will continue to offer technical assistance. |

Package & shipping

6. Packaging and shippingPackaging Detail: standard exporting package or depend on customers' demand.1 packaged in plasticfilm.2 pallet or wood box.3 ground fixed bolt to confirm steady and avoid damage.4 tightly belf to fasten machine in container.Delivry Detail: normally within 30 days after receive deposit.