125T4000 CNC Press Brake for metal sheet stainless plate

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | Paypal, D/P, D/A, T/T, WU |

| Supply Ability: | about 400 set/month |

| Place of Origin: | Anhui |

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | wc67y-125t4000 |

|---|---|

| Means of Transport: | Ocean, Land |

| Power: | Hydraulic |

| Raw Material: | Sheet / Plate Rolling |

| Machine Type: | Press Brake |

| Extra Services: | End Forming |

| Automation: | Automatic |

| Certification: | CE |

| Material / Metal Processed: | Stainless Steel |

| Brand Name: | durmapress |

| Norminal Pressure: | 1250KN |

| Worktable Length: | 4000mm |

| Poles distance: | 2510mm |

| Throat depth: | 320mm |

| Stroke: | 200mm |

| Open height: | 450mm |

| Power: | 11kw |

| Dimension: | 3200x1900x2700 |

| Main motor: | Siemens from Germany |

| Hydraulic system: | Bosch-Rexroth from Germany |

| Production Capacity: | about 400 set/month |

| Packing: | Wooden package of the both angle notcher |

| Delivery Date: | 30 days |

Product Description

Ma'anshan durmapress Machinery Technology Co., Ltd mainly produces "Tenroy" brand press brake, shearing machine, rolling machine, punch press, air duct making machine, press brake tools, punch press tools and shearing blades etc. Our products are sold throughout the country, exported to more than 80 countries.

Sophisticated equipment and specialized manufacturing, provide us a strong guarantee for the large-scale growth and quality assurance on high-tech products. Tenroy has a number of professional products installation and commissioning workshop and precision parts processing workshop, owing numerical control milling planer, large-scale numerical control boring lathe, numerical control horizontal type treating center etc.

Tenroy always regard "quality first, credibility first, customer first" as purpose, and "blaze new trails, people-oriented" as the spirit of our enterprise. We provide first-class service for customers and a platform for our staff members. We'd like to provide our full support to our new and old customers! So as to help the company that handle with sheet metal manufacturing production create efficiency, and reduce each product processing costs to the minimum.

Features

1.All Steel Welded, Vibration eliminate stress, high mechanical intensity, good rigidity.Hydraulic uppertransmission, steady and reliable.

2. Mechanical stop dog, synchronization in twist axis, high precision.

3.Back gauge distance, upper ram stroke can be adjusted by motor-drive,manual operation micro-adjustequipment, numerical display.

4.WE WORKTABLE full deflection compensation

Basic Main Components

1.NC display: Korea

2 Main Seal: PARKER

3.Main electronic element: Siemens/Schneider

4 Main Motor

5 Group valev

6.Conjugate internal gear pump

7.Back gauge

8.Mould

9.Oil cylinder

10.Front Plate Feeding will be equipped

11.Free charge Standard Upper and Down Mould

Main Character and Function

All the components of the machine are designed under the instruction of the Computer aided design and software of CAD/CAE/CAM to fully guarantee the intensity and rigidity of all the components.

The whole body under total wielded, thickness and reliable in machine body with high-rigidity and good in shock absorption reduction.

The machine structure are composed by body frame, working table, slide block, main cylinder and backgauge.The advantage design and produce style can ensure the machine usage and high precision.The main produce procedure as below(all process under strictly inspection)

Plate stock----physical and chemical inspection----Plate Pre-treatment (Rust-Cleaning) --- CNC flame Cutting-- Cutting the welded joint----Group Welding----Gas Shielded Welding---Ageing treatment----Milling Planer working----The Assembly of finished products

The machine body, Slide Block, Working table and other main components are under one time clamping of large landing boring and milling machine to ensure several geometric accuracy of the main machine.

The machine is greatly enhanced in anti-torque and electronic load resistance. Machine can normally work in full loaded situation. Working table, Upright Column, Crossbeam and Ram are good and high in design rigidity. Little deformation between the working table and ram when work to guarantee good straightness and uniformity in angle.

Machine's main components under guaranteed quality or trustable company

The motor and electronic system elements are all composed from Siemens or Schneider

Dies can be designed under clients' requirement.

Oil pump can be used from China chengjie enterprise who is used in China's Aircraft industry.Or we can use Germany ECKERLER enterprises.

The seal will be from USA Parker or Japan Valqua company.

The hydraulic system and valve optional Germany BOSCH company.

The security protection equipment: We equipped protect fence to avoid any penetration inside and foot controller with emergency control button

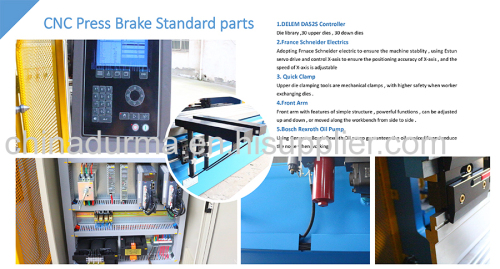

ü THE STANDARD COMPONENTS |

1. ESUNTUN E21 CNC SYSTEM 2. SIEMENS OR SCHNEIDER ELECTRONIC ELEMENTS 3. USA PARKER SEAL 4. GERMANY REXORTH HYDRAULIC SYSTEM 5. CHINA YONGSHUN HIGH QUALITY GEAR PUMP 6. SIEMENS MOTOR or CHINA FAR EAST Motor (Because of SIEMENS Motor made in China has long delivery period, if the special voltage , we will not use SIEMENS unless the client can accept the long delivery period for machine also. Mostly the normal voltage , the delivery is 30 days for motor. We also use a lot of Motor named CHINA FAR EAST, it's quality has been proved with several years working. ) 7. CHINA JIANHU CYLINDER HAS CHROMATE TREATMETN 8. PUNCH AND DIES: T8A 9. SECTION PUNCH AND DIES AVAIALABE IF THE CLIENT NEEDS SMALL SLIP PUNCH BENDING 10. BACK-GAUGE: ALLOY HIGH QUALITY STANDARD 11. PIPES : ANTI-RUST PHOSPHORIZATION PIPES WITH BOTH INSIDE AND OUTSIDE ANTI-RUST TREATED 12. PIPE CONNECTOR: HIGH QUALITY CONNCTOR FROM SHANGHAI COMPANY WITH HIGH QUALTY SEAL INSIDE TO PREVEND THE LEAKAGE OF THE HYDRAULC OIL. 13. REAR DOOR WITH OPEN-DOOR POWER-OFF FUNCTION FOR SECURITY 14. BOTH ENTRANCE AND EXIST OF THE HYDRAULIC OIL TANK, FILTER IS EQUIPPED. 15. MECHANICAL PUNCH RELEASE CLAMP |

ü OPTIONAL COMPONENTS |

1. SECTION PUNCH AND DIES –PLEASE PROVIDE US THE DIMENSION IF NEEDED 2. THE FREQUENCY TRANSFORMER---THE PRICE USD 3. FAST RELEASED CLAMP---USD600/SET MACHINE 4. BALL SCREW BACKGAUGE FINGERS---USD250/SET MACHIN |

ü ESTUN E21 BRIFT INTRODUCTION |

1. ESTUN E21 is a simple CNC control system designed to replace ESTUN E200 with lower price. 2. ESTUN is jointed company by HOLLAND DELEM AND CHINA ESTUN 3. ESTUN E21can control X axis working into position accurately 4. ESTUN E21 will work better accompany with FREQUENCY TRANSFORMER. FREQUENCY TRANSFORMER is not the standard components ,optional. 5. Can programme the software for future usage and has memory 6. Can set up different steps in one programme. 7. Timer can control the bending time 8. Control X/Y two axis 9. The operation manual is available 10. The install manual is available |

How about your machine quality?We are worry about the quality.

| |

Whether the machine price can be more discount DURMAPRESS always provide high quality machine,as we know ,oversea market is more important and difficult than domestic market because of communication time costing after sales,So always,our machine has enough qaulity standard to make sure the machine can work more than the real warranty period.In this way ,we will save a lot and think in advance for the clients. | |

How about your manufactory in CHINA DURMAPRESS located in HAIAN CITY,NANTONG,JIANGSU province who is the leading area in China and also in the worldwide as the center of the metal plate solution machines,We have worked about 10 years in this area and totally have about 150 staffs.Rich experience in this field with professional technical supporting and oriented service. | |

Do you accept L/C payment term?

|

Technical documents included:

1.Manual instruction (including hydraulic scheme, schematic circuit diagram and machine base map.

2.Verification certificate.

3.Packing list (including the technical documents).

4.Machine color is standard and is customerized according to customer's requirements.

Technical training:

Tenroy company is responsible for the user operator training and also we will provide a training software to you.

Quality assurance:

Our company is responsible for the maintenance during the use period (damage that caused by improper operation, the user should bear the repair charge). Warranty is 12 months after the end debugging.