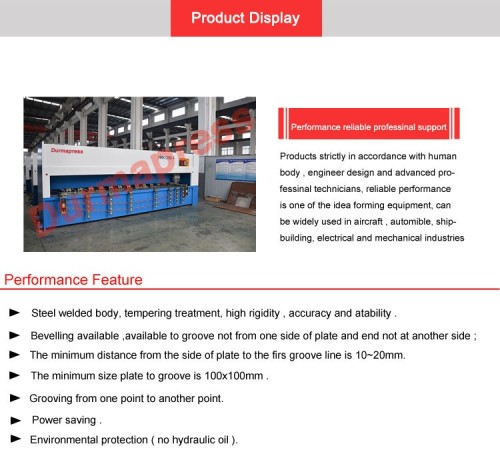

metal sheet cutting machine 4000mm length cnc v grooving machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CIF,DAT,DDP,DAP,CIP,CPT |

| Payment Terms: | Paypal, L/C, D/P, T/T, Money Gram |

| Supply Ability: | about 400 set/month |

| Place of Origin: | Anhui |

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 4Ax4000mm |

|---|---|

| Means of Transport: | Ocean, Land |

| Power: | Hydraulic |

| Raw Material: | Sheet / Plate Rolling |

| Machine Type: | Others |

| Extra Services: | End Forming |

| Automation: | Automatic |

| Certification: | CE |

| Material / Metal Processed: | Stainless Steel |

| Brand Name: | durmapress |

| Product name: | V cutting machine |

| motor brand: | siemens - germany |

| Electrics: | Schneider- Germany |

| warranty: | 5 years |

| Keyword: | Automatic Punching Machine |

| Application: | Metal Sheet Stamping |

| Usage: | Pressing Metal Products |

| Material: | Q235 |

| Brand: | durmapress |

| Production Capacity: | about 400 set/month |

| Packing: | Wooden package of the machine |

| Delivery Date: | 30 days after deposit confirmed |

Product Description

Ma'anshan Maanshan Durmapress Machinery Technology Co., Ltd mainly produces "Tenroy" brand press brake, shearing machine, rolling machine, punch press, air duct making machine, press brake tools, punch press tools and shearing blades etc. Our products are sold throughout the country, exported to more than 80 countries.

Sophisticated equipment and specialized manufacturing, provide us a strong guarantee for the large-scale growth and quality assurance on high-tech products. Tenroy has a number of professional products installation and commissioning workshop and precision parts processing workshop, owing numerical control milling planer, large-scale numerical control boring lathe, numerical control horizontal type treating center etc.

| 1.The equipment adopts the big pitched ball screw and high torqued servo motors as the main drive, which makes knives more stable and faster when processing. |

| 2.The worktable of high strong plate as the surface makes the workpieces not easy to wear in machining. |

| 3.A panel with the adjustable fuselage during the workpiece activities makes the point to every bit of mesa precision in 0.02 mm distance that within. |

| 4.Equipment which adopts PLC man-machine interface programming allows the operating personnel easy to understand and locate accurately. |

Advantages of V groover machine : |

1. Bevelling available 2. Available to groove not from one side of plate and end not at another side 3. The mininum distance from the side of plate to the firs groove line is 10-12mm 4. The mininum size of plate to groove is 100x100mm 5. Grooving from one point to another point 6. Power saving 7. Environmental protection (no hydraulic oil ) |

This CNC V Groover Machine is the upgrade machine at the foundation of Japan Amada sheet metal v slotting machine!

Our machine has all the properties of traditional models,so as to address a range of issues encountered

by customers adequately in the actual operation.

Main Device

| High precision ball screw | Taiwan TBI |

| Precision linear guide rail | Taiwan HIWIN |

| Angular contact ball bearings | NSK of Japan |

| Planing white steel blade | SECO of Sweden |

| Servo motor | Yaskawa of Japan |

| PLC | Yaskawa of Japan |

| Electrical components | Schneider of France |

| Power cable | IGUS of Germany |

| Pneumatic components | Taiwan AIRTAC |

Main parameters

| Name | 4Ax4000mm |

| Processing Width | 850-1500mm |

| Processing Length | 4000mm |

| Processing Thickness | 0.5-6mm |

| The back and front moving distance of beam | 850-1500mm |

| Moving speed of beam | 50-5000mm/min |

| The maximum left and right moving distance of carriage | 4300mm |

| The maximun moving speed of carriage | 50mm/min |

| Deviation of length | ±0.05mm |

| Location percision | ±0.05mm |

| The maximum travel of knife rest | 100mm |

Our service

1.Installation Service

We dispatch technician to customer's factory for installation and preparation of machine operation. ( Customers only need to pay for the air fare and hotel .)

2.Training Service

Our technicians are available to your factory and provide training on how to use the machine. As well, you may send your technician to our company to learn how to operate machines. ( Customers only need to pay for the air fare and hotel. )

3.Quality Guarantee

We arrange final test before shipment. After making sure machine is in the best condition, we make shipment.

Machine warranty is 5 years.

Packing & shipping

FAQ:

1.How about your automatic portable press brake quality?

Better is a mature brand in CHINA,through our many years research in technology. our design including structure and detailed security and precision has enhanced greatly,and can match all the CE standard or more strict standard.Our machines distribute worldwide to about 50 countries where there are metal plate industry ,there are Better machines.

2. What's your after-sale service?

Better provide oriented after-sales service including the oversea engineers training available and also international dealer center for any emergency guidance.We have established worldwide network to guarantee our timely response for your any demand no matter where are you.

We welcome engineers from your side to learn the technical design and normal maintenance here,this will help your easy in understanding and helpful if you need to be our dealer.

3. How to operate your automatic portable press brake?

Don't worry,we have our company own CD/Manual to show you along with the machine.So you can learn this from the existing documents to deepen your knowledge and understanding. Anyhow there are another way is through internet video face to face for machine teaching, because of the high development in internet,the world has become smaller and you can easy catch us if any assistance needed