C-Frame Mechanical power Press

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CIF |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | about 400 set/month |

| Place of Origin: | Anhui |

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | J23 |

|---|---|

| Means of Transport: | Ocean, Land |

| Power: | Hydraulic |

| Raw Material: | Sheet / Plate Rolling |

| Machine Type: | Press Brake |

| Extra Services: | End Forming |

| Automation: | Manual |

| Certification: | CE |

| Material / Metal Processed: | Carbon Steel |

| Brand Name: | durmapress |

| Normial Force: | 100KN |

| Slipper Stroke: | 150mm |

| Slipper stroke times: | 50Times/min |

| Max.Closing Height: | 200mm |

| Connecting Rod adjuster: | 30mm |

| Throat Depth: | 130mm |

| Pole Distance: | 40mm |

| Angle of inclination: | 30 ° |

| Motor Power: | 1.5KW |

| Weight: | 450KG |

| Production Capacity: | about 400 set/month |

| Packing: | Wooden package of the both angle notcher |

| Delivery Date: | 30 days |

Product Description

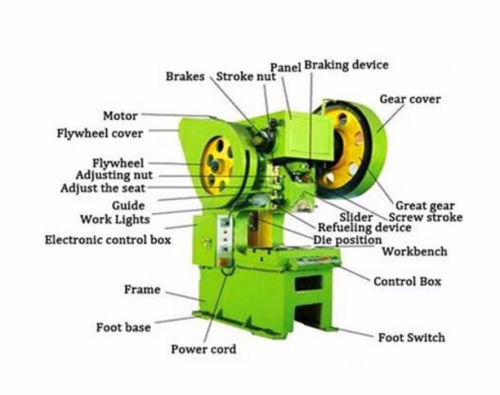

D type Power Press Machines with adjustable inclinable power press

Main functions:

Adopts horizontally placed crankshaft.

Stroke adjustment device mounted on crankshaft.

Rigid rotated bond clutch.

Manual shut height adjustment with scale display.

Main specification:

JC23-6.3D | J23-10D | J23-16D | J23-25D | JG23-40D | JC23-63D | J23-80D | ||

Capacity | kN | 63 | 100 | 160 | 250 | 400 | 630 | 800 |

Nominal Force | mm | 2 | 2 | 2 | 2.5 | 4 | 4 | 5 |

Slide Stroke | mm | 0-40 | 0-60 | 0-70 | 0-80 | 20-120 | 20-120 | 10-130 |

SPM | min-1 | 170 | 145 | 125 | 60 | 55 | 50 | 45 |

Max. Die Height | mm | 105 | 130 | 170 | 180 | 220 | 260 | 270 |

Die Height Adjustment | mm | 20 | 35 | 30 | 45 | 70 | 80 | 80 |

Between Slide Center & Frame | mm | 110 | 130 | 170 | 210 | 260 | 260 | 270 |

Bolster (FB×LR) | mm | 200×310 | 240×360 | 320×480 | 400×600 | 480×710 | 480×710 | 520×860 |

Bolster Opening (Dia.×FB×LR) | mm | φ60 | φ120×20 | φ100 | φ120 | φ220×25 | φ200×45 | φ200×45 |

Bolster Thickness | mm | 40 | 50 | 60 | 70 | 80 | 90 | 100 |

Bolster Opening (Dia.×FB×LR) | mm | φ140×110 | φ130×90 | φ210×160 | φ180×130 | φ200×150 | φ250×200 | φ250×200 |

Slide Area (FB×LR) | mm | 120×140 | 150×170 | 180×200 | 210×250 | 270×320 | 280×320 | 280×380 |

Shank Hole (Dia.×Dpth) | mm | φ30×55 | φ30×55 | φ40×60 | φ40×70 | φ50×70 | φ50×80 | φ60×75 |

Max. Inclined Angle | ° | 30° | 25° | 25° | 25° | 25° | 25° | 20° |

Between Columns | mm | 150 | 180 | 220 | 260 | 300 | 350 | 410 |

Motor Power | kW | 0.75 | 1.1 | 1.5 | 2.2 | 4 | 5.5 | 7.5 |

Outline Size (FB×LR×H) | mm | 780×610 | 915×700 | 1150×900 | 1325×990 | 1600×1180 | 1810×1350 | 1810×1410 |

Net Weight | kg | 360 | 600 | 1080 | 1900 | 3180 | 4218 | 5240 |

J23series open-type inclinable press widely used in precision electronics, communications, computers, household appliances, auto parts, motor stator and rotor of small precision parts such as stamping process. Standard J23 Series open tilting press working load big, strong impact resistance, smooth and reliable, single punch, straight punch to adjust optional.J23-80 J23-80 and above products are configured on the balance-lift cylinder, balancing the slide, on the model's own weight, to prevent transmission reverse the force caused by the phenomenon of lead before, so that movement is extremely smooth, to avoid and eliminate rod and the sliding block gap, reducing the impact force and wear parts to extend the service life of parts and components to prevent fracture due to brake failure or link the fall when the slider, the effective protection of machine damage and personal safety.

With the integration of special cast iron alloy, high rigidity and resistance to shock. The long-based guide-way slider design, with a slide balance device to ensure the functioning of precision and stability. All anti-wear components are electronic timer automatic lubrication systems, such as a lack of lubrication, punch the automatic stop. \ Advanced and simple control system to ensure the accuracy of the slider and stop running. Can be used with any of the automated production demands, improve productivity and reduce costs.

Center of gravity balance

1. Transmission center and the center of the machine as a whole line to ensure accurate punching and stable.

2.. The machine uses two sliders equalizer to ensure balanced operation of the machine.

Operation of a reliable, safe :

Clutch / brake device a high degree of sensitivity, coupled with top international double electromagnetic devices and over-load protection device to ensure the punch slider and stop running the accuracy and security.

Slider to adjust the body 0.1mm Adjust the precision of up to 0.1mm, adjust the production is more safe and efficient.

A stable high-precision Crankshaft, gears, gear shafts and other parts of friction were characterized by hardening heat treatment and then grinding process, there is a high wear resistance and balance and stable performance.

Process automation, labor-saving technology Can be used with any of the automatic feed mechanism, automated production, reduce costs and improve efficiency.

Environmental : Advanced design concepts, low noise, low-cost, energy saving.

DURMAPRESS brand mechanical Power Presses are coming in both C frame and Pillar type versions from 3 tons to 250 tons capacity in most economical type of construction with several std/optional features such as manual/auto lubrication. systems; knockouts electronics hand safety; single/double or un-geared versions as also pneumatic feeders/ straightness and de-coilers for automation Purpose

Steel body fixed, Inclinable type power press

Fram : The frame is of all steel construction, fabricated from Rolled steel plates with suitable cross ribbings. Presses upto 30T will be supplied with C.I. legs. proper alignment of the frame is ensured by machining.

Clutch : The clutchis of pin/rolling key-type. the clutch is rigid and well supported. the clutch gives continuous strokes for mass production

Crank Shaft : Crank shaft is made of special alloy steel machined to close accuracy and fitted in bronze bushes for smooth working, longer life & accuracy

Flywheel : Properly sized flywheel, is made of high grade cast iron, for storing and releasing adequate energy for the pressing operations, and properly balanced for smooth running

Gears : Gear are of steel cast or fabricated. Gear teeth are generated by precision hobbing machine

Table & Ram : Table and fam are made pf high grade heavy duty cast iron & properly seasoned. They are perfectly aligned, to each other to obtain high accuracy & precision press operation

Lubrication : An efficient shot luvrication system has been provided for lubricating the sliding surfaces and moving parts. The lubricant is applied by hand pump

Inclining : Inclinable type presses are provided with inclining mechanism which can be easily det and locked in

Mechanism : Position by spanners within minutes. the press ils so designed that even in maximum inclined position, it is stable under heavy pressing load

Standard Accessories

1.., Motor pulley

2.., Clutch key

3.., Clutch key springs

4.., Slide adj. spanner

5.., Fly wheel & grar guard

6.., Oil cups for lubrication point

7.., Knock-out system

8.., inclination arrangement in 50 ton & abovem

Optional Accessories

1.., Tow hand operated clutch

2.., Single / continuous stroke

3.., Lubrication pump automatic

4.., Electrical

5.., Tie - rod

6.., Tommy bar

7.., Extra base plate

8.., Inclination arrangement

Certification

our customer

RFQ

How about your machine quality? We are worry about the quality.

RE: Durmapress a mature brand in CHINA, through our 20 years research in technology,our design including structure and detailed security and precision has enhanced greatly,and can match all the CE standard or more strict standard. Ou

machines distribute worldwide to about 50 countries where there are metal plate industry, there are Brillante machines. And any nations use our machines,there are good reputation and terminal user satisfaction.

Whether the machine price can be more discount?

RE:1.We always provide high quality machine, as we know,oversea market is more important and difficult than domestic market because of communication time costing after sales, so our machine follows qaulity standard to make sure the machine can work more than the real warranty period. In this way,we will save a lot and think in advance for the client.

RE:2. we are sure to provide quality=price and price=quality ,the matched price and acceptable for the clients and durable for our machines.We welcome your negotiate with us and get a good satisfaction.

Our Service

1 We have more than ten years of experience in the production of machine tools, and we have a good team for your service

2. We have strict quality control system.

3.We accept OEM&ODM according to your requirement.

4.We will deliver as soon as possible once place the orders.

5.You can contact us at any time .

We can manufacture all kinds of the machines, if you have any request, please contact us soon. Feel free to email me, we will reply you within 12 hours.

RFQ

Q:How about your machine quality?

A:Our machines distribute worldwide to about 50 countries where there are metal plate industry ,there are Brillante machines.And where there are our machines,there are good reputation and terminal user satisfaction.

Q:The machine price can be more discount?

A: We think about our price level,we are sure to provide quality=price and pice=quality ,the matched price and acceptable for the clients and durable for our machines.We welcome your negotiate with us and get a good satisfaction. and Increase the order quality or long-term cooperation in the future will get our discount.

Q: Where is your factory?

A:We located in Ma'anShan City, Our factory is particularly close to Nanjing, about an hour, if you are to visit the factory .We can pick you up at the airport.Welcome to visit our factory!

Warranty

Our guarantee time is 5 years from B/L date. If any component is damaged during guarantee time, we can send the component to the customer by DHL, TNT freely.

Our factory can send our engineer to the customer's factory install, commission and training freely. The customer provide the double trip tickets, food and accommodation for our engineer. The customer also can send the engineer to our factory to learn the operation and maintains freely.

Our factory provide the service for the customer forever, if the customer need operation help, can contact us by wechat, Skype, Email , whatsapp and Telephone at any time, we provide 24 hours on-line service.