D type Power Press Machines with adjustable inclinable power press

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CIF |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | about 400 set/month |

| Place of Origin: | Anhui |

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | J23 |

|---|---|

| Means of Transport: | Ocean, Land |

| Power: | Hydraulic |

| Raw Material: | Sheet / Plate Rolling |

| Machine Type: | Press Brake |

| Extra Services: | End Forming |

| Automation: | Manual |

| Certification: | CE |

| Material / Metal Processed: | Carbon Steel |

| Brand Name: | durmapress |

| Normial Force: | 100KN |

| Slipper Stroke: | 150mm |

| Slipper stroke times: | 50Times/min |

| Max.Closing Height: | 200mm |

| Connecting Rod adjuster: | 30mm |

| Throat Depth: | 130mm |

| Pole Distance: | 40mm |

| Angle of inclination: | 30 ° |

| Motor Power: | 1.5KW |

| Weight: | 450KG |

| Production Capacity: | about 400 set/month |

| Packing: | Wooden package of the both angle notcher |

| Delivery Date: | 30 days |

Product Description

More Pictures

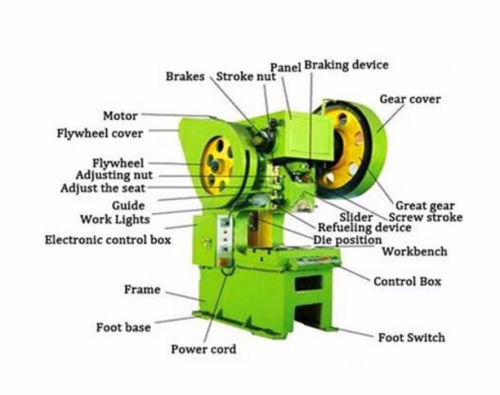

Front view of the machine:

The worktable:

Worktable tiltable:

Main motor:

Slider:

More details:

Structure of machine:

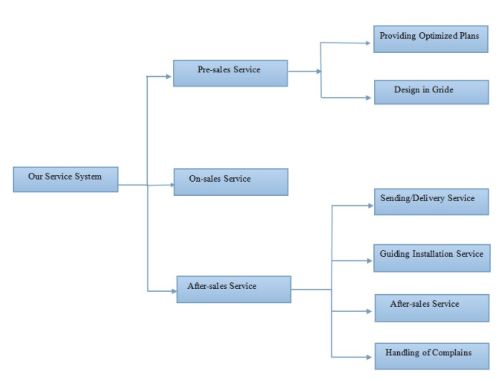

OUR SERVISE

Product Description

Features:

| The Machine of Whole structure |

| (1).C- frame provides maximum rigidity and minimum deflection for accurate parts and long tool life. |

| Steel-welded frame, high rigidity and less deformation Compact. Thick plates and large columns provide |

| you with the stable platform you need for your demanding application. |

| (2).Wide body frame eliminating vibration for improved IDE life and machine, which means economical |

| and practical. Operation space is wide, and the movable bolster could be moved out of frame to set the |

| die. The structure is simple and the appliance is also beautiful. |

| (3).High accuracy, high efficiency, simple and convenient operation, good performance, favorable price |

| and best service. |

| Transmission control and brake systems |

| (1). Use the combine of dry friction clutch and brake pneumatic, rigid interlocking, reliable piece of |

| friction material semimetallic friction material SMFM88, less pollution, long life. With the transfer torque, |

| rotational inertia is small, smooth transmission, flexible operation, convenient of installation and |

| maintenance |

| (2).Die height adjustment of slider with manual mode, the scale display. Extended by four triangular rail, |

| easy adjustment. |

| (3).Use double safety valve to ensure the accurate implementation of the clutch instruction. |

| (4).Electrical control is installed PLC, 8 group cam controller, reliable action. |

| (5).Electrical control adopts Omron PLC for centralized control, improved machine reliability |

| (6).Proximity switch with 8 groups consisting of Schneider cam controller, reliable synchronization |

| detection and monitoring. |

| (7).Machine is with both hands button and foot switch to achieve continuous, single and inching |

| practices. |

| (8).Can move the RAM up slowly, which allows the operator to control Mold adjustment conveniently. |

| RAM adjustment and Structure |

| (1).Adjustable stroke machine, slide stroke to achieve a certain level within the range of adjustable, body |

| steel plate welded structure, the whole body is tempered, use the secondary transmission, the |

| transmission, part of the crankshaft horizontal Placement, flywheel and gear are the external open |

| style, easy maintenance. |

| (2).Slider is a cast box structure and rigid. Collapse of the sliderstyle installation of pressure overload |

| protection device, simple structure, if the slider overload, the fuse collapse is damaged, then protect the |

| machine tool and die from damage. |

| Electrical system and the safety interlock |

| (1).Electrical components are imported or fromSinoforeign joint Venture, in accordance with |

| international standards, reliable safety, long life, good anti-interference ability, a radiation unit is |

| fitted in electrical cabinet. |

| (2).Protective fence and the safety interlock to ensure the operation safety. Have a movable single-hand |

| pedal switch, easy to operate. |

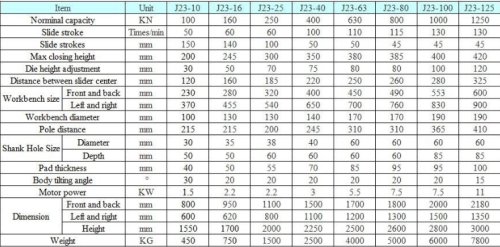

Parameter:

Our Service

1.Installation Service

We dispatch technician to customer's factory for installation and preoperation of machines. (Customers only need to pay for the airfare and hotel expense.)

2.Training Service

Our technician is available to your factory and offer training of how to use our machines. As well, you may send your technician to our company to learn how to operate machines. ( Customers only need to pay for the airfare and hotel expense.)

3.Quality Guarantee

We arrange a final test before shipment. We will make shipments after making sure machine is in the best performance.

Machine warranty is 5 years.

Certifications

CUSTOMER VISIT

Our Service

Quality and Service Assurance:

1.we have Q & C department in our factory and our engineer have much experience and can design the suitable machine for our clients.

2.our machine can produce the nice production, can guarantee good quality.the production is confirm to the national standard even the international standard

3.the products should not have scratch and the flatness

Technical R & D Department: design teams for different kind of production line.

package:

1.As to the roll forming machine's package, it should be nude.

2.we'll protect the machine well before shipment, to prevent machines from rusting and damage.

Repairs:

Warranty: 1 year since the date of B / L on

Installation and Commissioning:. We will send professional engineers to buyers' country for installation and commissioning Buyer pays each engineer 100USD / Day besides the round-tickets, room and board.

OUR TEAM

DURMA SUCCESSFUL CASE

DURMA OFFICE

Packing & Delivery