8*3200 new model hydraulic cnc shearing machine in stock

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU |

| Supply Ability: | about 400 set/month |

| Place of Origin: | Anhui |

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Means of Transport: | Ocean, Land |

|---|---|

| Power: | Hydraulic |

| Raw Material: | Sheet / Plate Rolling |

| Machine Type: | Others |

| Extra Services: | End Forming |

| Automation: | Automatic |

| Certification: | CE |

| Material / Metal Processed: | Stainless Steel |

| Brand Name: | durmapress |

| Product name: | hyraulic shearing machine |

| cutting thickness: | 6mm |

| cutting width: | 3200mm |

| Warranty: | 5 years |

| Control system: | Estun E21 NC Control |

| vlave brand: | Bosch - Germany |

| motor brand: | siemens - germany |

| Electrics: | Schneider- Germany |

| blades: | Cr6W2Si |

| Cutting speed: | 8-12 times/ munite |

| Production Capacity: | about 400 set/month |

| Packing: | Wooden package of the machine |

| Delivery Date: | 30 days after deposit confirmed |

Product Description

1. Description of hydraulic cnc shearing machine

Hydraulic shears is by moving the upper blade and a fixed down blade, using reasonable blade clearance, shear force is applied to the metal plate so that the plate separation by size needed break. That specially for the aviation, the llght industry, the building, the electric power and so on .

2. Features of Hengjian hydraulic cnc shearing machine

1.Special numeric-control system is fitted with mainframe of the bending machine.

2.Multi-work-step programming function is able to achieve an automatic operation and continuous positioning of multi-step procures, as well as an automatic precision adjustment for positions of rear stopper and gliding block.

3.The machine is provided with bend counting function, for a real-time display of processing quantity and power failure memory of positions of stopper and gliding block, Special numeric-control system is fitted with mainframe

of the bending machine.

4.Multi-work-step programming function is able to achieve an automatic operation and continuous positioning of multi-step procures, as well as an automatic precision adjustment for positions of rear stopper and gliding block.

5.The machine is provided with bend counting function, for a real-time display of processing quantity and power failure memory of positions of stopper and gliding block, as well as procedures and parameters.

6.Imported ball bearing lead screw and linear guide rail are used for rear stopper, to ensure the positioning precision of rear stopper, for processing precision of machine to be higher.

7.as well as procedures and parameters.

8.Imported ball bearing lead screw and linear guide rail are used for rear stopper, to ensure the positioning precision of rear stopper, for processing precision of machine to be higher.

3. Detail phpto of Hengjian hydraulic cnc shearing machine

3.1 the body of machine

1. Standard Configuration:

ESTUN E21S CNC controller

Backgauge X-axis electric control

DELTA frequency converter

Controller suspension arm and front material supporter

HIWIN ball screw and polished bar, control accuracy 0.05mm

Germany EMB tube connector

Germany Bosch Rexroth integrated hydraulic valve

Germany Siemens main motor

Germany Schneider electrics

Hydraulic and electrical overload protection

Light align

Blade materials (6CrW2Si)

South Korea KACON petal switch

Safety standards ( 2006/42/EC )

The electrical cabinet and the front safeguard door open to power off

Domestic pedal switch (safety grade 4)

Rear metal safeguard rail, CE standard

Safety relay monitors pedal switch, safety protection

High-definition LCD panel

Control motors and frequency converters

X-axis intelligent positioning

Multi-step programming, 40 programs, each program 25 steps

Built-in time relay

One-button switching function

Unilateral positioning function

One-key backup and restore of parameters

Both Chinese and English language

Metric system

2. Safety Identification:

3. ESTUN E21S CNC system:

Streamlined design originated from EU, the machine frame is a whole through overall welding and annealing treatment.

Reliable Germany Rexroth integrated hydraulic system and hydraulic transmission; the design can effectively reduce problems caused by leakage of hydraulic fluid.

Hydraulic swing beam shearing machine is one kind of equipment by swinging the upper blade to shear plate with smaller shearing angle and distortion, improving shearing quality.

Backgauge is adjusted by high-precision ball screw driven by E21S controller, during the process frequency convertor prevent positioning device horizontal swinging, significantly improving positioning accuracy.

Light aligning device, convenient for manual operation; pressure cylinder with built-in spring mechanism and bottom end furnished with special material gasket to prevent aluminum or other soft materials from being imprinted.

Made by high-quality alloy tool steel, the machine can meet the requirements of impacting load and high wear resistance when working.

Light and practical cantilever referring to man-machine engineering design, easy NC operation interface with features of high precision and more comfortable.

The worktable adopts the rolling steel ball to reduce the frictional resistance, protect the work piece surface; novel protective devices complying with safety specifications: protecting the operator's personal safety; ingenious design: petty material can be cutter easily.

Front material supporter is equipped with Perpendicularity and positioning regulator to ensure the cutting accuracy, easy operation, practical and efficient.

Rapid adjustment mechanism for rearranging blade clearance, simple operation by hand and adjusting steplessly.

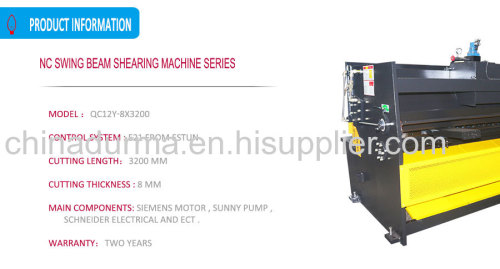

ITEMS | PARAMETER | UNIT |

Model | QC12Y-8X3200 | set |

Cutting Thickness | 8 | mm |

Cutting Width | 3200 | mm |

Cutting Angle | 1°30′ | 0 |

Backgauge Range | 20-600 | mm |

Stroke Number | ≥10 | times/min |

Main Motor | 5.5 | kw |

Weight | 6500 | kg |

Overall Dimension | 4600X1800X1700 | LXWXH in mm |

Hydraulic system of CNC hydraulic shearing machine

1. BOSCH hydraulic control system, more reliable and easy for maintenance. The hydraulic system consists of motor, oil pump and valve groups.

2. Every complete working cycle can be achieved through the control of hydraulic valve. The remote adjustment valve can adjust the working pressure at the right side of the wall board.

3. All seals use Japan NOK good quality and high performance

4. Overload overflow protection is outfitted to hydraulic system, which can assure no leakage, and the oil level can be read or seen directly.

5 Durmapress maintenance after sale

1. This product's warranty period is one year, and it enjoys life-long maintenance.

2. If users modify machine without permission of our technology department, and make the machine get damaged, at this condition we won't maintain the machine for free.

3. In the warranty period, if the machine gets damaged because users operate it improperly, materials expenses will be needed.

4. Out the warranty period, we will ask for materials expense and travel expense.

Packaging & Shipping

4. paching and delivery of hydraulic cnc shearing machine

Packaging Detail: standard exporting package

1. packaged in plasticfilm.

2. pallet or wood box.

3. ground fixed bolt to confirm steady and avoid destory.

4. tightly exporting standard belf to fasten machine in container.

Delivry Detail: Within 30 days after receive deposit