200T3200 manual stainless steel pipe bending machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | Paypal, D/P, D/A, T/T, WU |

| Supply Ability: | about 400 set/month |

| Place of Origin: | Anhui |

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | WC67Y/K-200T3200 |

|---|---|

| Means of Transport: | Ocean, Land |

| Power: | Hydraulic |

| Raw Material: | Sheet / Plate Rolling |

| Machine Type: | Press Brake |

| Extra Services: | End Forming |

| Automation: | Automatic |

| Certification: | CE |

| Material / Metal Processed: | Stainless Steel |

| Brand Name: | durmapress |

| Norminal Pressure: | 630KN |

| Worktable Length: | 2500mm |

| Poles distance: | 1970mm |

| Throat depth: | 250mm |

| Stroke: | 100mm |

| Open height: | 320mm |

| Power: | 5.5kw |

| Dimension: | 3200x1600x2200 |

| Main motor: | Siemens from Germany |

| Hydraulic system: | Bosch-Rexroth from Germany |

| Production Capacity: | about 400 set/month |

| Packing: | Wooden package of the both angle notcher |

| Delivery Date: | 30 days |

Product Description

Ma'anshan Durmapress Machinery Technology Co., Ltd mainly produces "Tenroy" brand press brake, shearing machine, rolling machine, punch press, air duct making machine, press brake tools, punch press tools and shearing blades etc. Our products are sold throughout the country, exported to more than 80 countries.

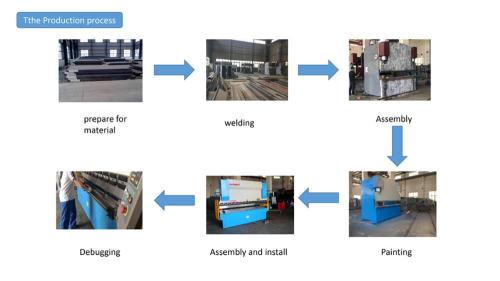

Sophisticated equipment and specialized manufacturing, provide us a strong guarantee for the large-scale growth and quality assurance on high-tech products. Tenroy has a number of professional products installation and commissioning workshop and precision parts processing workshop, owing numerical control milling planer, large-scale numerical control boring lathe, numerical control horizontal type treating center etc.

Tenroy always regard "quality first, credibility first, customer first" as purpose, and "blaze new trails, people-oriented" as the spirit of our enterprise. We provide first-class service for customers and a platform for our staff members. We'd like to provide our full support to our new and old customers! So as to help the company that handle with sheet metal manufacturing production create efficiency, and reduce each product processing costs to the minimum.

We sincerely wish all the friends work together for a common development!

Main feature

1. The frame is steel structure, left and right vertical plate, table and pressure plate welded into a unitary structure, after welding to eliminate internal stress by tempering, exceptional rigidity, high stability.

2. Important parts of the frame, sliders, etc. are used ANSYS finite element analysis software to ensure machine reliability.

3. Hydraulic drive, cylinder on both end of machine, disposed on the slider to drive it work directly.

4. Torsion axis synchronization for slide synchronous mechanism.

5. Adopt a mechanical stopper mechanism, stable and reliable.

6. Back Gauge size and slide stroke controlled by CNC system, back gauge with high precision ball screw, stable operation and precise positioning.

7. The CNC system adopts frequency conversion control technology, with multi-step

programming function, simple and easy to operate.

8. Inclined wedge deflection on the compensation mechanism, in order to guarantee access to high bending accuracy

9. Safety barrier device all around the machinery, electrical cabinets equipped with Open door cut-off function, emergency stop button around front and back, protective cover foot switch to ensure safe working.

Application:

It is suitable for forming process of SMC materials and other plastic material.

Particularly applied in the following:

A. Compression moulding of SMC sheet (glass fibre reinforced plastic)

B. Auto industry: steel ring, vehicle body,chasis, axle housing, oil tank,door,etc.

C.Home electric appliance industry: components of air conditioner, refrigerator, washing machine, microwave oven, electric cooker and so on.

| 1. Standard Service: |

Our factory provide the service for the customer forever, if the customer need operation help, can contact us by MSN, Skype, Email and Telephone at any time, we provide 24 hours on-line service. |

| 2. Installation: |

Our factory can send our engineer to the customer's factory install, commission and training freely .The customer provide the double trip tickets, food and accommodation for our engineer. The customer also can send the engineer to our factory to learn the operation and maintains freely. |

| 3. Quality Guarantee: |

Our guarantee time is 14 months from B/L Date ,If any component is damaged during guarantee time,we can send the component to the customer By DHL,TNT freely. |

| 4. Order Processing: |

FAQ

Q1: How can i get the after-service?

A: We provide one year guarantee and lifelong maintenance.

We will send you the spare parts freely if the problems caused by us.

Any problem, you can call us directly.

Q2: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory.

Our factory address: Bowang industry park,Maanshan City,China

Our factory is near Nanjing Lukou Airport.We can pick you up in the airport.

Hotel booking service is available .

Q3:Are you a factory or trade company?

A: We are manufacturer with own factory for 9 year, export proportion 50~60%.

Q4:How can i trust your company?

A:With 9-years-professional design, we can provide you suitable suggestion and lowest price

1. Assessed by third party, national patents and CE, ISO for all equipment, .

2. Welcome to inspect anytime. We are near to Nanjing Lukou Airport.

3. For our machine, we do very well on hydraulic balers,hydraulic shears,iron work.

Q5 :Is your price competitive?

A: Only good quality machine we supply. Surely we will give you best factory price based on

superior product and service.