manual sheet metal plate rolling machine price

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CIF |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | about 400 set/month |

| Place of Origin: | Anhui |

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | w11-20*2500 |

|---|---|

| Means of Transport: | Ocean, Land |

| Power: | Hydraulic |

| Raw Material: | Sheet / Plate Rolling |

| Machine Type: | Press Brake |

| Extra Services: | End Forming |

| Automation: | Manual |

| Certification: | CE |

| Material / Metal Processed: | Carbon Steel |

| Brand Name: | durmapress |

| Condition: | New |

| Material: | Stainless Steel |

| Extra Services: | Machining |

| Item: | Steel plate rolling machine |

| Voltage: | 220V/380V/415V/440V |

| max thickness of coiled plate: | 20mm |

| max width of coiled plate: | 2500mm |

| diameter of top shaft: | 30mm |

| diameter of buttom shaft: | 260mm |

| main power: | 15kw |

| Production Capacity: | about 400 set/month |

| Packing: | Wooden package of the both angle notcher |

| Delivery Date: | 30 days |

Product Description

Rolling machine introduce:

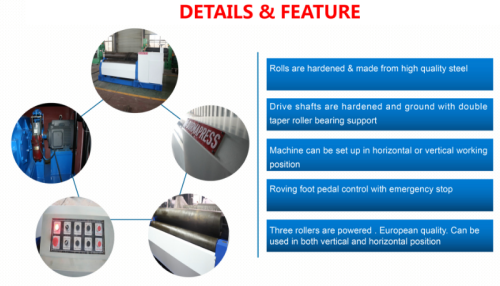

W11 Series 3 rollers rolling machine use mechanical driven mechanism,upper roller can be

dispatched with feed roller.Special side wheel can be installed according to customers'

special requirement,in order to pprocess different kind of material,such as angle steel

rolling ,round steel pipe rolling and etc.

The Function and Application Scope of the Machinery

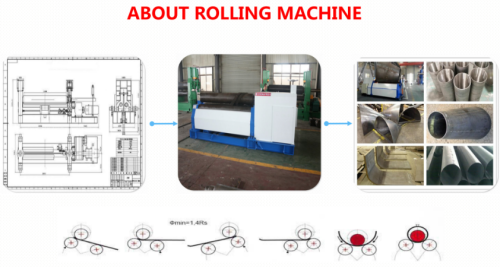

This is threeroller symmetric rolling equipment. It is mainly used in the process of cold working

in which the sheets within

the thickness of 20mm can be bent into different diameter cylindrical tubes.

It is widely used in boiler, chemical industry, mining, construction, shipbuilding and other

machinery industry.

Main Structure and Working Principle of Machinery

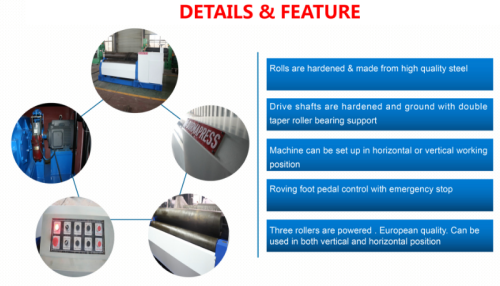

1,This is symmetric bending machine. The cylinder rolling is completed by the upper

roller which pressing to the

lower one and the mutual rolling.

2,The machine consists of two parts, the operation part and the transmission part which

are welded at the whole bottom pallet. The operation part consists of left and right bearing

housing, one upper roller, two lower rollers, lifting gears and some accessories. The lower

roller is the main one, upper roller can be adjusted at the height.

The transmission part consists with the main motor, speed-reducing motor and other accessories.

3,The lower roller is driven by the main motor through the main reduce. The main reductor output shaft transmits

to the two lower rollers through a group of gear wheel. The roller driving direction is switched by the main motor.

4,The elevation movement of the upper roller is realized by the auxiliary motor through the auxiliary reductor,

which drives worm and worm wheel under the left and right roller bearing to move automatically, makes the steel

wire nut which is fixed on the worm wheel rotating, and completed by up and down movement of ball bearing

screws accordingly.

5,The offloading device is used after the round cylinder have been finished. Before leaving the left bearing seat,

raises the upper roller to standard height, and make the upper roller stop with balance pull rod at the bottom of

upper roller. Then draw out pin shaft on the tilting bearing seat, overturn the tilting bearing seat, then the coiled

product can emerge from one end of the upper roller.

6,The main components are: three 45 steel forged rollers, HRC35-45, support frame is welded, process after

being welded, the lower pallet is a welded part. Ball bearing screw

andworm gear are 45 steel forged parts.

7,Electrical parts is adopted famous apparatus, steady performance, durable, safe and reliable, operates conveniently.

Rolling machine Configuartion:

| 1. Main motor-Siemens,Germany |

| 2.Oil Pump-Sunny ,USA |

| 3. Hydraulic Valves-Bosch Rexroth Germany |

| 4.Reducer-Lida, Sino-USA |

| 5. Gear-Sanxin |

| 6. Electrics-Schneider, France |

| 7.Sealings-NOK, Japan |

| 8. Roller-Nanjing |

Rolling machine Model:

| Model no. | max.bending thickness (mm) | bending width (mm) | min.bending diameter(mm) | top roller diameter(mm) | motor power (KW) | yield limit (Mpa) |

| W11-6x1500plate bending | 6 | 1500 | 450 | 170 | 5.5 | 245 |

| W11-3x3200 plate bending | 3 | 3200 | 450 | 170 | 5.5 | 245 |

| W11-4x2500 plate bending | 4 | 2500 | 450 | 170 | 5.5 | 245 |

| W11-6x2000 plate bending | 6 | 2000 | 450 | 170 | 5.5 | 245 |

| W11-8x2500 plate bending | 8 | 2500 | 600 | 240 | 7.5 | 245 |

| W11-10x2000 plate bending | 10 | 2000 | 600 | 220 | 7.5 | 245 |

| W11-10x2500 | 10 | 2500 | 600 | 250 | 11 | 245 |

| W11-10x3000 plate bending | 10 | 3000 | 650 | 250 | 11 | 245 |

| W11-12x2000 plate bending | 12 | 2000 | 600 | 240 | 7.5 | 245 |

| W11-12x2500 plate bending | 12 | 2500 | 650 | 260 | 11 | 245 |

| W11-16x2000 | 16 | 2000 | 650 | 260 | 11 | 245 |

| W11-12x3000 | 12 | 3000 | 700 | 280 | 11 | 245 |

| W11-12x3200 | 12 | 3200 | 700 | 280 | 11 | 245 |

| W11-16x2500 | 16 | 2500 | 700 | 280 | 11 | 245 |

| W11-20x2000 | 20 | 2000 | 700 | 280 | 11 | 245 |

| W11-25x2000 | 25 | 2000 | 850 | 340 | 15 | 245 |

| W11-20x2500 | 20 | 2500 | 850 | 340 | 15 | 245 |

| W11-16x3200 | 16 | 3200 | 850 | 340 | 15 | 245 |

| W11-25x2500 plate bending | 25 | 2500 | 850 | 370 | 22 | 245 |

Quality & Service: At Durmapress, our #1 priority has always been providing our clients with great quality products and superior customer service. |

Quick lead Time: We're dedicated to providing the quickest turn-around times and work very hard to ensure that all of your deadlines are met |

Unbeatable Prices: We continuously strive to find ways of reducing our production costs, and passing the saving over to you! |

Brand Awareness: The goal of any strong brand is achieve a level of awareness that instills the idea of quality and value into all of your potential customers. |

Special Offers:In order to maintain our competitive edge, we are constantly running special offers on our Best –selling press brake, forging equipment goods and design services. Contact our sales term to see how we can help you save a lot of money. |

RFQ

*We have our own factory and brand; Our machines can match all the CE standard or more strict ones.

*Quality assurance: 5 years warranty and 100% quality inspection before packing.

*Service:Impeccable after-sale service, and all your problem will be solved within 24 hours.

*Price: Can be negotiable according to the qty.

*MOQ:1 set.

*Howtovisit:You can fly to NanJing LuKou airport directly,you can also take high- speed train to Nanjing

South Station from other city in China.We will pick you up in the airport or Train station.