nc hydraulics guillotine shearing machine hydraulic shearing machine 12mm

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,DDP,DAP,CIP,EXW |

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 25 sets per month of the guillotine shearing |

| Place of Origin: | Anhui |

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | QC11Y-12x3200 |

|---|---|

| Means of Transport: | Ocean, Land |

| Power: | Hydraulic |

| Raw Material: | Sheet / Plate Rolling |

| Machine Type: | Others |

| Extra Services: | Cut To Length |

| Automation: | Automatic |

| Certification: | CE |

| Material / Metal Processed: | Aluminum |

| Brand Name: | Durmapress |

| Name: | Guillotine shearing machine |

| Control system: | E21s |

| Motor: | Siemens from Germany |

| Pump: | Sunny from USA |

| Thickness: | 12mm |

| Width: | 3200mm |

| Warranty: | 1year |

| Power: | 7.5KW |

| Process material: | Metal plate |

| Stanless thickness cutting: | 6mm |

| Production Capacity: | 25 sets per month of the guillotine shearing |

| Packing: | PVC film coved the sheariing machine for container fixed |

| Delivery Date: | 20 days of the guillotine shearing machine |

Product Description

Product Description

nc hydraulics guillotine shearing machine,hydraulic shearing machine 12mm

1. It is the second generation of hydraulic plate shearing machine, machine frame and knife rest are welded integral;

2. Vibration eliminates stress, precision is kept well, the advanced integrated hydraulic system is reliable;

3. Adpot three-point support rolling guide to eliminate gas between supports and improve shearing quality;

4. Gas between baldes is adjusted with hand-operated wheels, so it is quick, exact and convenient;

5. The four rectangular baldes all can be used for a long time;

6. The up knife rest adopts interior inclining structure for faling conveniently and improving precision;

7. Certification: ISO9001, SGS, CE;

Model | QC11K-12x3200 |

Max cutting thickness | 12MM |

Max cutting length | 3200MM |

Cutting material | Mild steel, stainless steel, aluminum, copper, ect |

Cutting angle | 0.5-2.5° |

Throat depth | 120MM |

Back-guage Range | 10-900MM |

Strokes | 10cycle/min |

Main motor | 18.5Kw |

Weight | 10200Kg |

Dimension | 3800*2000*2200MM |

The whole structure of machine and Characteristics:

1. Totally European design, streamlined looking, Frame: consists of right and left wall boards, working table, oil tank, slot steel and etc.

2. The stress of the welded parts can be eliminated by vibration.

3. The machine enjoys high accuracy and high strength and can be transported easily.

4. As the cutting beam has been designed in inner-inclined structure, it is easy for plates to fall down and the accuracy of products can also be guaranteed.

5. High accuracy, high efficiency, simple and convenient operation, good performance, favorable price and best service.

6. The machine by the European Union CE certification and ISO quality system certification

7. Adopt integrated hydraulic control system, more reliable and easy for maintenance.

8. The cutting times of this machining tool is displayed on a MD11-1 NC and accurately show the cut after the back gauge size and number display.

9. Adopt handwheel to rapidly and accurately adjust the blade clearance, Shearing in sections, shadow-line cutting.

10. Shearing angle is variable, which can reduce the shearing deformation of sheet metal and can shear much thicker sheet metal.

COMPONENTS:

Operation System: MD11-1 (Hongkong)

Oil pump(Gear Pump): Chengjie(Shanghai)

Blade:Jinshang (Shanghai) Material: 6crw2si /9crsi

Hydraulic Valves: Rexroth (Germany)/Omega(U.S.A.)/ (Janhu,China)

Electric parts: Siemens Germany/Shanghai CHINT

Main Seal:VALQUA(Japan)/NOK(Japan)

All components also can supply according to client's requirement.

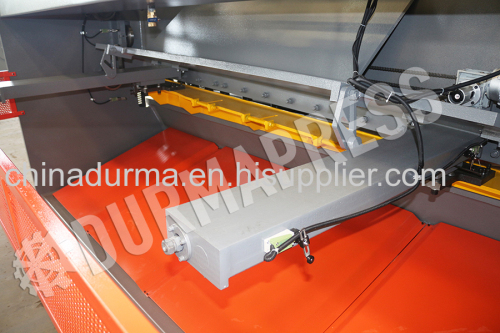

Detailed Photo of machine

Product Detail

| Color | red and black,or according to your demand |

| Backguage | 10-800 |

| Screw | Ball screw option |

| NC controller | SNC18 |

| Warranty | 100% one year |

| Electrical component | Siemens |

| Blade | Alloy steel |

| Hydraulic oil | 46# |

| Product Keywords | 2.5m hydraulic beam cutter |