6mm steel plate automatic hydraulic sheet metal cutting machine with E21s control system

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,DDP,DAP,CIP,EXW |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 400 set month |

| Place of Origin: | Anhui |

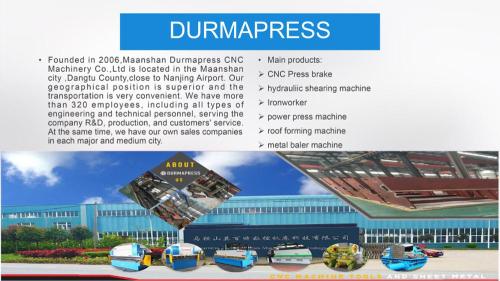

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | QC12Y-6*3200 |

|---|---|

| Means of Transport: | Ocean, Land |

| Power: | Hydraulic |

| Raw Material: | Sheet / Plate Rolling |

| Machine Type: | Pipe End Forming Machine |

| Extra Services: | End Forming |

| Automation: | Automatic |

| Certification: | CE |

| Material / Metal Processed: | Carbon Steel |

| Brand Name: | DURMAPRESS |

| Cutting thickness: | 6 mm |

| cutting width: | 3200mm |

| stopper adjust range: | 20-500mm |

| power: | 7.5KW |

| dimension: | 3840*1710*1620mm |

| Main Motor: | Siemens Germany |

| Siemens Germany: | Customer pointed |

| Warranty: | 5 years |

| Type: | Plate Shearing Machine price |

| Seal ring: | Valqua |

| Production Capacity: | 400 set month |

| Packing: | Wooden package of the both angle notcher |

| Delivery Date: | 30 days |

Product Description

Product Description

6mm steel plate automatic hydraulic sheet metal cutting machine with E21s control system

Product Application

Widely used in shipbuilding, boiler, aviation, bridges, utilities, chemicals, metal structures and machinery manufacturing industries.

Main Features

1.Steel plate welded construction, hydraulic drive, nitrogen cylinder return.

2.Convenient operation, reliable performance and beautiful appearance.

3.Blade gap adjustment has the instruction board to display. The adjustment is convenient and quick.

4.It has the lighting device and can adjust the travel volume of the up shaft to any extent.

5.Working area has the fence type personal safety protection devices.

6.Back gauge size and cutting times both have the digital display device.

Main Features: |

| 1.Totally EU streamlined design,Monoblock by welding robots & aparatus and stress relief process by Annealing treatment. |

| 2.Accurl engineers utilize parametric 3D SolidWorks using FEM & DOE analysis as well as static and mechanism analysis. |

| 3.Accurl Hydraulic Shearing Machine is a Swing Beam Action machine which is produced in a variety of cutting lengths and capacity options. |

| 3. Adopt integrated hydraulic system, more reliable and easy for maintenance. and the hydraulic system from Bosch-Rexroth, Germany, |

| 4. Equipped with lighting-alignment, so as to align when shearing. The stroke of knife beam can be adjusted in stepless mode. |

5. Hydraulic drive, return of knife beam is smooth and prompt by nitrogen cylinder. |

| 6. CE conformity including Tiltable Fornt Finger Guard and Optical Rear Safety Guard, |

7. Safe fence and the electric interlocker have been designed for the machine to ensure the operation safety. |

| Standard Equipment: |

| 1. Rapid and precise blade clearance adjustment by single handle on the side frame |

| 2. Multi Edge Blades for cutting Aluminium, Mild Steel and Stainless Steel |

| 3. Cutting Line Illumination and wire for shadow line cutting |

| 4. Counter of Strokes, Cutting Length Adjustment |

5. Hydraulic and Electrical overload protection |

6. Squaring Arm and Front Support Arms |

7. Estun E21s NC control |

| 8. Germany Bosch-Rexroth Hydraulic |

| 9. Telemecanique/SchneiderElectrics |

| 10. Hydraulic and Electrical overload protection |

11. Delta inverter with ball screw and polished rod with 0,05 mm accuracy. |

12. Side guard is standard meeting CE regulations. |

|

Better Cuttings: |

1.Backgauge adjustment according to blade gap. |

2.Backgauge retraction feature. |

3.Sub-program and programming loop. |

4.Sequence repeat function. |

5.Auto cutting (Flying cut). |

|

| Estun E21s NC Shearing Machine Control system: |

| 1. Monochrome LCD Box Panel. |

| 2. Integral factor programmable freely |

| 3. Automatic positioning control |

| 4.Spindle allowance offset |

| 5.Internal time relay |

| 6.Stock counter |

7.Backgauge position display, resolution in 0.05mm |

The best cutting results You can cutt longer and narrow parts with standard AC/MS7-Cutt Series. |

Main Features

MAXIMUM SOLIDITY:

The robust monolithic structure is a guarantee of great stability and precision of cut. Even the design is perfected according to criteria of maximum functionality and efficiency, such as to reduce maintenance and operator interventions to the minimum.

Certifications

Pre-Sales Service

* Technical solution.

* Online video authentication machine work.

* Cutting samples provided by DHL

After-Sales Service

* Supplier will provide detail manual for software, hardware

and trouble shooting, also supplier should give necessary

guidance online if Buyer need. If it's necessary, Buyer

should send regular his technical staff to Supplier for

technical training.

6mm CNC sheet metal shearing machine used hydraulic steel plate cutting machine

Specification of hydraulic cnc sheet metal cutting machine

type | Cutting thickness (T*W)mm | Cutting angle | Stroke time (min-1) | Stopper adjust range mm | Power (KW) | Dimension L*W*H(mm) |

QC12Y-4*2500 | 4*2500 | 1°30′ | 18 | 20-500 | 4 | 3200*1650*1620 |

QC12Y-4*3200 | 4*3200 | 1°30′ | 14 | 20-500 | 5.5 | 3900*1650*1620 |

QC12Y-4*4000 | 4*4000 | 1°30′ | 12 | 20-500 | 7.5 | 4700*1900*1800 |

QC12Y-6*2500 | 6*2500 | 1°30′ | 18 | 20-500 | 7.5 | 3200*1650*1620 |

QC12Y-6*3200 | 6*3200 | 1°30′ | 14 | 20-500 | 7.5 | 3900*1650*1620 |

QC12Y-6*4000 | 6*4000 | 1°30′ | 12 | 20-500 | 7.5 | 4700*1900*1800 |

QC12Y-8*2500 | 8*2500 | 1°30′ | 14 | 20-500 | 7.5 | 3200*1650*1620 |

QC12Y-8*3200 | 8*3200 | 1°30′ | 12 | 20-500 | 11 | 4000*1650*1620 |

QC12Y-8*4000 | 8*4000 | 1°30′ | 10 | 20-500 | 11 | 4600*1650*1620 |

Our Services

Quality, service and commitment

1, product design, manufacturing, sales and service the whole process in strict accordance with ISO9001 quality system standards.

2, quality Three Guarantees, one year, lifelong provide parts and maintenance services.

3, free installation guide and responsible for commissioning hydraulic used sheet metal shearing machines

More informations about hydraulic iron plate cutting machine price,contact us freely