multiple functions Q35Y-20 hydraulic metal ironworker

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,DDP,DAP,CIP,CPT,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 600 sets per year for hydraulic ironworker |

| Place of Origin: | Anhui |

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | Q35Y 20 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand Name: | Durmapress |

| Norminal pressure: | 90Ton |

| Voltage: | 380V/220V Optional |

| Name: | punching and shearing machine |

| Color: | gray and black,or by customer |

| Max. thickness cutting: | 20mm |

| 90 degree shearing: | 140x140x12mm |

| Throat depth: | 355mm |

| Max. punching diameter: | 20mm |

| Square bar: | 50x50mm |

| Round bar: | 50mm |

| Production Capacity: | 600 sets per year for hydraulic ironworker |

| Packing: | PVC film covered punching and shearing machine |

| Delivery Date: | 7 workdays after confirm the deposit |

Product Description

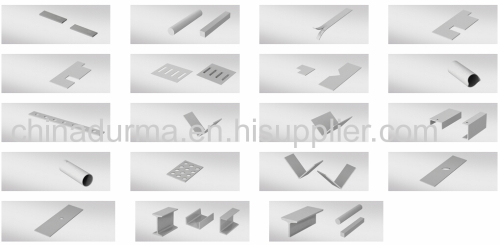

The series of Q35y muti-funciton hydraulic ironworker machine is a latest product of punching and shearing machine which can punch,die cut ,shear and bend all kinds of meterials such as plate,flat bar,square bar,round bar,equal,angle,channel,I-beam and so on.It has the advantages of simple operation,low energe consumption and low maintenance cost.It has become a perferred choice of modern manufacturing industry.The machines have been get European Union certification and ISO quality system certification.All machines are supplied with standard tooling including repetition support tables at punch, Comprehensive safety guards are fitted as standard on all work stations.

The hydraulic system is activated by two shielded foot controls for two operator utilization. one operating the punch end cylinder, the other operating the shear end cylinder.The shear cylinder provides the power to the three shearing and the notch stations.Easy for maintenance with centralized lubrication system.

The series of Q35y muti-funciton hydraulic ironworker machine is a latest product of punching and shearing machine which can punch,die cut ,shear and bend all kinds of meterials such as plate,flat bar,square bar,round bar,equal,angle,channel,I-beam and so on.It has the advantages of simple operation,low energe consumption and low maintenance cost.It has become a perferred choice of modern manufacturing industry.The machines have been get European Union certification and ISO quality system certification.All machines are supplied with standard tooling including repetition support tables at punch, Comprehensive safety guards are fitted as standard on all work stations.

The hydraulic system is activated by two shielded foot controls for two operator utilization. one operating the punch end cylinder, the other operating the shear end cylinder.The shear cylinder provides the power to the three shearing and the notch stations.Easy for maintenance with centralized lubrication system.

Punching section

Including punching hole ,suqare hole ,waist shaped slot machining and bear the mold ( optional Hitachi SDK11 imported materials),widely used in iron to bridge construction,ship fittings,steel structure other industry.

Note:In the punching station,through the mold can be achieved with special features of bending and impact blinds.

Multi-function shearing section

The shear type steel including channel steel,angle steel,I-beam steel ,suqare steel and so on sheat port level.Goods are available in all varieties and simple operation.The angle shear has the ability to cut angle at 45° both top and bottom leg.

Otherwise. we can modify the shear plate's size according to actual needs of users.

Notching section

The notching section of this hydraulic ironworker is perfect for notching out metal plate,angle iron and much more.The notching station alse has an oversized table with material stops.This section of the machine can also be outfitted with the optional vee notcher.

Product application | |||

1.steel structure processing | 7.high and low pressure railway parts processing | ||

2.elevator car and parts processing | 8.wind power tower on the staircase and pedal parts processing | ||

3.trailer | 9.conveyor bracket and other parts processing | ||

4.belt conveyor,mix station processing | 10.grain and oil processing equipment bracket shell small starch equipment | ||

5.threshing machine body,trailer car parts processing | 11.railway truck crane parts processing | ||

6.slaughtering equipment rack and parts processing | 12.all kinds of steel shearing,cutting,punching | ||

Factory view

Maanshan Durmapress Machinery Technology Co.,Ltd located is known as"China blade mold machine" reputation first rural town of Bowan--Maanshan eastern outskirts of Economic and Tehnological Development Zone industrial Park Bowang,from the Nanjing Lukou international Airport is only 26KM and strategic ,traffiic is developed.

The main products named "Yuanyi" hydraulic ironworkers have been desighed and built to the highest quality standards in the industry.We always stick to our core value--"Quality of build quality,casting brand integrity",and try our best to serve better.Our company has many successful experience of producing multi-function hydraulic ironworker,its products are sold throughout china and more than 20 countries and regions.In adidtion,we have been highly recognized by our partners and clients all over the wold.