Q35Y-25 round Steel rod cutting and notching machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CIF |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 400 SET MONTH |

| Place of Origin: | Anhui |

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | Q35Y 25 |

|---|---|

| Means of Transport: | Ocean |

| Power: | Hydraulic |

| Raw Material: | Sheet / Plate Rolling |

| Machine Type: | Beading Machine |

| Extra Services: | End Forming |

| Automation: | Automatic |

| Certification: | CE |

| Material / Metal Processed: | Aluminum |

| Brand Name: | DURMAPRESS |

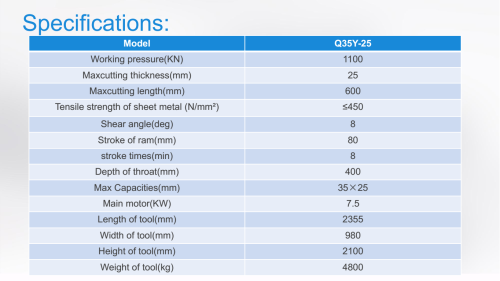

| Punching pressure: | 115T |

| Max cutting thickness: | 25mm |

| Shearing size of one stroke: | 16*250 8*400 |

| Slipper stroke: | 80mm |

| Throat depth: | 400mm |

| Punching thickness: | 25mm |

| Max punching diameter: | 35mm |

| Main motor power: | 7.5KW |

| Dimension: | 2350*960*1090 |

| Color: | green |

| Production Capacity: | 400 SET MONTH |

| Packing: | moisture proof film. can also be with pallet or wood box. |

| Delivery Date: | 30 DAYS |

Product Description

Product Name: Durmapress High Quality CNC hydraulic press brake, Bending machine,

Hot sale hydraulic press brake

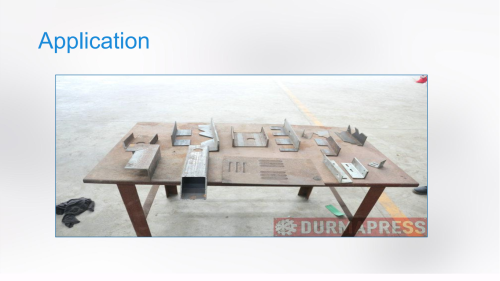

Product Application

The folded sheet metal bending machine has high productivity and high working accuracy,

using different shapes of up and down mould, can be bent into various shapes artifacts,

slider stroke at a time can be to a bending forming of sheet metal, after a lot of bending

can be achieved relatively complex shape workpiece, when equipped with the

corresponding equipment, can also make a punch and so on.

I. Structure and performance introduction:

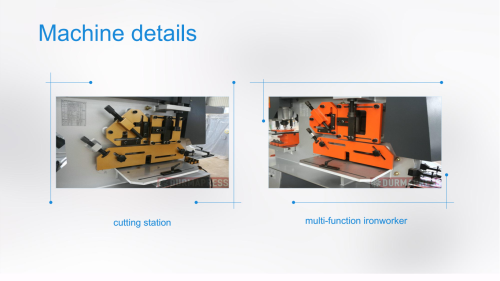

This series of products are ideal equipment for cutting all kinds of angle steel,

I-beam, U-shape steel, right angle or 45 degree angle steel. Multi-workstations

make it possible to finish series operations simultaneously on one machine,

such as punching, shearing and notching, Dual-piston-type combined punching

and shearing machine allows two-man operation at the same time (stamping

+another work station), German Rexroth's integrated hydraulic valve block ensures

the stability of the machine, Through Thermal Effect of annealing processing, the

entire rack is able to keep its shape forever, without deformation. The introduction

of imported brand accessories ensures the parts' service life and use precision.

Punching: effective punching can be achieved with the machine, and stamping die

is easy to be replaced.

Bar cutting: you can quickly cut the round bar and square steel, if you want to cut

U-shaped, I-beam or T-profile section steel only by exchanging the cutting blade

and the operation procedure is very simple.

Angle cutting: you can cut several 90 ° and 45 ° angles with the help of special

dies.

Metal Sheet Bending: it is very easy to fulfill the daily metal sheet bending work

by making the bending moulds.

Notching: The machine is equipped with a large-shaped slotting blade head,

which can meet your general use, as to, special shaping blade head can be

customized.

II. Main functions:

2 independent hydraulic piston rods and foot-pedal allows two people operating

at the same time.

More efficient stroke-control functions of piston rod.

Central lubricating system

Motor-driven rear stopper

Lighting devices for work

5 independent work-positions: punch pin and die (standard punching dies),cutting

blade group for round and square steel, shearing blades for steel plate, slotting

and angle-cutting blade.

RFQ

Q: How to get a accurate quotation from us ?

A:Prvide us the details of material , such as metal thickness and width .

Q:You are manufacturer or trading company ?

A: We are 100% manufacturer with 17 year's manufaturer experience.

Q:Can you do OEM service ?

A:Yes, we can. your design is accepted , your own logo can be used on the machine.

Q:What's the shipping cost from china to your country ?

A:We can send machine to your port or door address by sea or airplane. please

kindly tell us your nearest port or address with postcode. we have reliable

shipping agent to insure the safe convenient and time delivery.

Q:Do you accept LC payment ?

A:Yes, normally our payment is 30%+70% ,LC payment is also acceptable

Q:How to operate this machine ?

A:Video line of our factory or we send you the moive directly.

Q:What about commissioning service ?

A: We can offer commissioning service , the buyer need to afford plane tickets.

Q:Do you offer teaching & training ?

A:Training at supplier's plant