hydraulic cnc cutter metal shearing machine 4mm metal plate

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | Paypal, L/C, T/T, WU |

| Supply Ability: | 30 sets per month for the shearing machine |

| Place of Origin: | Anhui |

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | QC12Y-4x3200 |

|---|---|

| Means of Transport: | Ocean, Land |

| Power: | Hydraulic |

| Raw Material: | Sheet / Plate Rolling |

| Machine Type: | Press Brake |

| Extra Services: | Cut To Length |

| Automation: | Automatic |

| Certification: | CE |

| Material / Metal Processed: | Carbon Steel |

| Brand Name: | Durmapress |

| cutting width: | 3200mm |

| Cutting thickness: | 4mm |

| control system: | E21s |

| Name: | Hydraulic shearing machine |

| Voltage: | 380V also can according to your local valtage |

| Cutting material: | Metal sheet , stainless steel sheet |

| Rate power: | 7.5KW |

| Weight: | 6Ton |

| Warranty: | 2 YEARS |

| Cutting stainless steel thickness: | 2mm |

| Production Capacity: | 30 sets per month for the shearing machine |

| Packing: | Inner with waterproof film,outside with wooden case. |

| Delivery Date: | 4weeks for sheet metal cutting machine |

Product Description

Product Description

cnc steel stainless plate sheet cut guillotine shearing machinery metal hydraulic shear metal shear machine qc11y/12y

1. Hydraulic individual sheet material clamping system with nylon inserts to protect material from indentation from the clamping cylinders along full length of machine.

2. Simplified blade gap adjustments to allow for a wide range of material types

3. Transfer balls inserted into work table allowing material to be easily moved to the cut position and squaring arm.

4.Totally European design,streamlined looking,Frame: consists of right and left wall boards, working table, oil box, slot steel and etc. The stress of the welded parts can be eliminated by vibration. The machine enjoys high accuracy and high strength and can be transported easily.

5.As the cutting beam has been designed in inner-inclined structure, it is easy for plates to fall down and the accuracy of products can also be guaranteed.

6.High accuracy, high efficiency, simple and convenient operation, good performance, favorable price and best service.

7.The machine by the European Union CE certification and ISO quality system certification

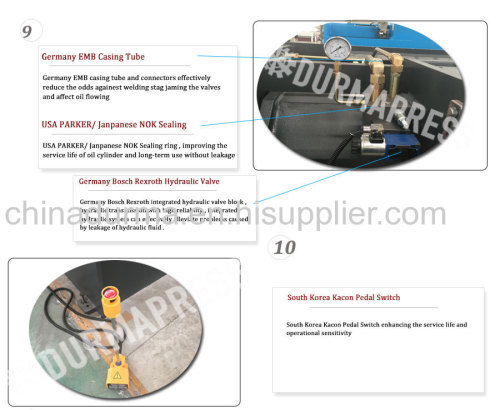

8.Adopt integrated hydraulic control system, more reliable and easy for maintenance. The hydraulic system consists of motor, oil pump and valve groups and it is installed at the top of the oil box.

9.Every complete working cycle can be achieved through the control of hydraulic valve.The remote adjustment valve can adjust the working pressure at the right side of the wall board.

10.All seals in cylinder is imported,the most famous brand,good quality and high performance

11.Overload overflow protection is outfitted to hydraulic system,which can assure no leakage,and the oil level can be read or seen directly

12.The cutting times of this machining tool is displayed on a Estun E10 NC and accurately show the cut after the block size and number display.

13.The parallelism of the sheet to be cut off and the precision of the shear size can be ensured. The cut stroke and cut times also can be controlled.

14.Light alignment device eases drawing line for cutting, Standard front support sheet frame, A set of standard blades

15.System uses a bladder-type hydraulic accumulator as an auxiliary energy,absorb the pressure shock,the machine is running smooth,low noise.

16.Adopt handwheel to rapidly and accurately adjust the blade clearance, Shearing in sections, shadow-line cutting.

17.The rectangular monoblock blades featuring long life with 4 cutting edges, quality high-carbon high-chrome blades D2 quality.

18. Shearing angle is Variable, which can reduce the shearing deformation of sheet metal and can shear much thicker sheet metal.

19.System uses a bladder-type hydraulic accumulator as an auxiliary energy,absorb the pressure shock,the machine is running smooth,low noise.

20.Optional:Holland Delem DAC350, DAC360, DAC310 or Estun E200 cnc controller automatically controls the backgauge, cutting stroke, cutting angle and the blades gap together the numbers of workpieces accurately.

21.European key electrics and Hydraulic Valves Advanced integral hydraulic system with good reliablity-Imported from Germany.

22.X axis back gauge clearance are controlled by E10s which ensures a higher cutting accuracy, Backgauge with Optional ball screw and line guide rail,, maximum stroke of backgauge can realize 1000mm.

| No | Model | Max cut thickness mm | Max cut length mm | Ram Stroke n/min | Cutting angle ° | Motor kw | Machine Szie mm |

| 1 | 4x2500 | 4 | 2500 | 20-40 | 0.5-1.5 | 5.5 | 3100x1600x1700 |

| 2 | 4x3200 | 4 | 3200 | 20-40 | 0.5-1.5 | 7.5 | 3800x1800x1700 |

| 3 | 6x2500 | 6 | 2500 | 16-35 | 0.5-1.5 | 7.5 | 3150x1650x1700 |

| 4 | 6x3200 | 6 | 3200 | 14-35 | 0.5-1.5 | 7.5 | 3860x1810x1750 |

| 5 | 6x4000 | 6 | 4000 | 10-30 | 0.51.5 | 7.5 | 4630x2030x1940 |

| 6 | 6x5000 | 6 | 5000 | 10-30 | 0.5-1.5 | 11 | 5660x2050x1950 |

| 7 | 6x6000 | 6 | 6000 | 8-25 | 0.5-1.5 | 11 | 6680x2200x2500 |

| 8 | 8x2500 | 8 | 2500 | 14-30 | 0.5-1.5 | 11 | 3170x1700x1700 |

| 9 | 8x3200 | 8 | 3200 | 12-30 | 0.5-1.5 | 11 | 3870x1810x1780 |

| 10 | 8x4000 | 8 | 4000 | 10-25 | 0.5-1.5 | 11 | 4680x1900x1860 |

| 11 | 8x5000 | 8 | 5000 | 10-25 | 0.5-1.5 | 15 | 5680x2250x2200 |

| 12 | 8x6000 | 8 | 6000 | 8-20 | 0.5-1.5 | 15 | 6800x2350x2700 |

| 13 | 10x2500 | 10 | 2500 | 10-25 | 0.5-2.0 | 15 | 3270x1730x1800 |

| 14 | 10x3200 | 10 | 3200 | 9-25 | 0.5-2.0 | 15 | 3990x2250x2200 |

| 15 | 10x4000 | 10 | 4000 | 6-20 | 0.5-2.0 | 15 | 4720x2490x2500 |

| 16 | 10x5000 | 10 | 5000 | 7-20 | 0.5-2.0 | 22 | 5720x2600x2800 |

| 17 | 10x6000 | 10 | 6000 | 6-20 | 0.5-2.0 | 30 | 6720x2500x2550 |

| 18 | 12x2500 | 12 | 2500 | 10-25 | 0.5-2.0 | 15 | 3270x1730x1800 |

| 19 | 12x3200 | 12 | 3200 | 9-25 | 0.5-2.0 | 15 | 3990x2250x2200 |

| 20 | 12x4000 | 12 | 4000 | 6-20 | 0.5-2.0 | 15 | 4720x2490x2500 |

| 21 | 12x5000 | 12 | 5000 | 7-20 | 0.5-2.0 | 22 | 5720x2600x2800 |

| 22 | 12x6000 | 12 | 6000 | 6-20 | 0.5-2.0 | 30 | 6720x2500x2550 |

Shipping and packaging

Standard packaging: Shearing machine is wrapped with plastic film and fixed by steel wires in the containers.

Size:6700*2100*3000mm

Optional packaging: Small machine can do metal box according to customer requirement.

FAQ

1, Q: Are you factory or trading company?

A: We are factory of rolling machine, bending machine and shearing machine, factory was established in 2001, with more than 15 years producing experience.

2, Q: What's your payment?

A: T/T, 30% deposit in advance, 70% balance before ship.

Irrevocable L/C at sight

3, Q: What's about delivery time?

A: For small model shearing machine, usually 15-20 days after received 30% deposit.

For big model shearing machine, about 30-45 days after received 30% deposit.

4, Q: We don't know how to use the machine, can you help us?

A: 1, We will send machine operation manual and CD together with machine;

2, If customer require, we will send technician to your factory teach you how to use it and maintain it;

3, You can send technician or workers to our factory, we will teach then how to use and maintain the machine.

5, Q: We are worry about the machine quality?

A: Our machine warranty is 3 years. Before ship the machine, we will test it about 7-10 days.