Hydraulic shearing machine for cutting stainless sheet & mild steel plate

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | Paypal, L/C, T/T, WU |

| Supply Ability: | 30 sets per month for the shearing machine |

| Place of Origin: | Anhui |

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

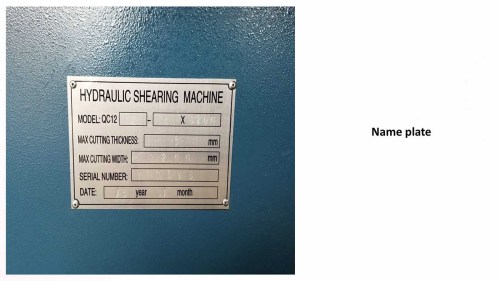

| Model No.: | QC12Y-6x3200 |

|---|---|

| Means of Transport: | Ocean, Land |

| Power: | Hydraulic |

| Raw Material: | Sheet / Plate Rolling |

| Machine Type: | Press Brake |

| Extra Services: | Machining |

| Automation: | Automatic |

| Certification: | CE |

| Material / Metal Processed: | Stainless Steel |

| Brand Name: | Durmapress |

| Cutting thickness: | 6mm |

| cutting width: | 3200mm |

| control system: | E21s |

| Name: | Hydraulic shearing machine |

| Cutting material: | Metal sheet , stainless steel sheet |

| Voltage: | 380V also can according to your local valtage |

| Weight: | 6Ton |

| Rate power: | 7.5KW |

| Brand: | Durmapress |

| Warranty: | 2 YEARS |

| Production Capacity: | 30 sets per month for the shearing machine |

| Packing: | Inner with waterproof film,outside with wooden case. |

| Delivery Date: | 4weeks for sheet metal cutting machine |

Product Description

Introduction

The machine with optional nc back gauge, electric and manual back gauge. The working gab and hydraulic part is very easy to adjust, widely used in metal sheet industry.

Whole steel welded frame with full strenght and rigidity.

Hydraulic press device with reliable safty bar.

Reply cutting stroke adjustment is adopted, cutting frame can be adjusted to ensure high cutting efficiency when cutting sheets with different thickness.

Back gauge station measured by motor-driven or by manual adopted.

With cutting counter device.

Light line for drawing straight line to cut metal plate.

Features:

Streamlined design originated from EU, the machine frame is a whole through overall welding and annealing treatment.

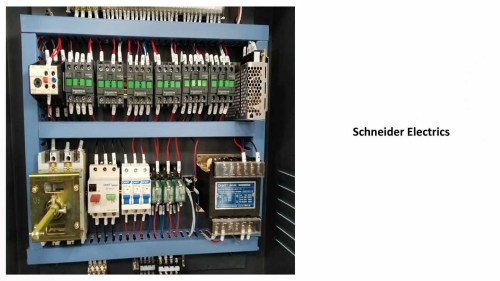

Reliable Germany Rexroth integrated hydraulic system and hydraulic transmission; the design can effectively reduce problems caused by leakage of hydraulic fluid.

Hydraulic swing beam shearing machine is one kind of equipment by swinging the upper blade to shear plate with smaller shearing angle and distortion, improving shearing quality.

Backgauge is adjusted by high-precision ball screw driven by E21S controller, during the process frequency convertor prevent positioning device horizontal swinging, significantly improving positioning accuracy.

Light aligning device, convenient for manual operation; pressure cylinder with built-in spring mechanism and bottom end furnished with special material gasket to prevent aluminum or other soft materials from being imprinted.

Made by high-quality alloy tool steel, the machine can meet the requirements of impacting load and high wear resistance when working.

Light and practical cantilever referring to man-machine engineering design, easy NC operation interface with features of high precision and more comfortable.

The worktable adopts the rolling steel ball to reduce the frictional resistance, protect the work piece surface; novel protective devices complying with safety specifications: protecting the operator's personal safety; ingenious design: petty material can be cutter easily.

Front material supporter is equipped with Perpendicularity and positioning regulator to ensure the cutting accuracy, easy operation, practical and efficient.

Rapid adjustment mechanism for rearranging blade clearance, simple operation by hand and adjusting steplessly.

High-definition LCD panel

Control motors and frequency converters

X-axis intelligent positioning

Multi-step programming, 40 programs, each program 25 steps

Built-in time relay

One-button switching function

Unilateral positioning function

One-key backup and restore of parameters

Both Chinese and English language

Metric system

Estun E21S NC control system:

Main cutting parameter

We product over 10 models hydraulic for cutting steel sheet with max thcikness from 4mm - 32mm.

Model | Cutting Thickness | Cutting Length | Cutting Angle | Travel Time | Backgauge Stroke | Motor | Dimension (L x W x H) |

mm(450N/m2) | mm | ° | Min-1 | mm | kw | Mm | |

4 x 2500 | 4 | 2500 | 1°30′ | 16 | 20~500 | 5.5 | 3040 x 1550 x 1550 |

4 x 3200 | 4 | 3200 | 1°30′ | 13 | 20~500 | 5.5 | 3840 x 1550 x 1550 |

4 x 4000 | 4 | 4000 | 1°30′ | 10 | 20~600 | 5.5 | 4600 x 1700 x 1700 |

4 x 6000 | 4 | 6000 | 1°30′ | 5 | 20~800 | 7.5 | 6460 x 2100 x 2300 |

6 x 2500 | 6 | 2500 | 1°30′ | 15 | 20~500 | 7.5 | 3040 x 1710 x 1620 |

6 x 3200 | 6 | 3200 | 1°30′ | 12 | 20~500 | 7.5 | 3840 x 1710 x 1620 |

6 x 4000 | 6 | 4000 | 1°30′ | 9 | 20~600 | 7.5 | 4620 x 1850 x 1700 |

6 x 5000 | 6 | 5000 | 1°30′ | 8 | 20~600 | 7.5 | 5640 x 1900 x 2000 |

6 x 6000 | 6 | 6000 | 1°30′ | 5 | 20~800 | 18.5 | 6480 x 2100 x 2300 |

8 x 2500 | 8 | 2500 | 1°30′ | 11 | 20~500 | 7.5 | 3040 x 1700 x 1700 |

8 x 3200 | 8 | 3200 | 1°30′ | 8 | 20~500 | 7.5 | 3860 x 1700 x 1700 |

8 x 4000 | 8 | 4000 | 1°30′ | 8 | 20~600 | 7.5 | 4640 x 1700 x 1700 |

8 x 5000 | 8 | 5000 | 1°30′ | 8 | 20~500 | 7.5 | 5400 x 2400 x 200 |

8 x 6000 | 8 | 6000 | 1°30′ | 8 | 20~800 | 18.5 | 6480 x 2100 x 2350 |

10 x 2500 | 10 | 2500 | 1°30′ | 8 | 20~500 | 7.5 | 3040 x 1800 x 1700 |

10 x 3200 | 10 | 3200 | 2° | 10 | 20~500 | 11 | 3860 x 2000 x 1700 |

10 x 4000 | 10 | 4000 | 2° | 10 | 20~600 | 11 | 4650 x 2100 x 2000 |

10 x 6000 | 10 | 6000 | 1°30′ | 10 | 20~800 | 18.5 | 6500 x 2100 x 2300 |

12 x 2500 | 12 | 2500 | 1°40′ | 12 | 20~600 | 18.5 | 3140 x 2050 x 2000 |

12 x 3200 | 12 | 3200 | 1°40′ | 10 | 20~600 | 18.5 | 3880 x 2150 x 2000 |

12 x 4000 | 12 | 4000 | 1°40′ | 10 | 20~600 | 18.5 | 4680 x 2150 x 2000 |

12 x 5000 | 12 | 5000 | 2° | 6 | 20~600 | 18.5 | 5800 x 2400 x 2400 |

12 x 6000 | 12 | 6000 | 2° | 5 | 20~800 | 22 | 6900 x 2600 x 2700 |

16 x 2500 | 16 | 2500 | 2°30′ | 10 | 20~100 | 18.5 | 3140 x 2150 x 2100 |

16 x 3200 | 16 | 3200 | 2°30′ | 10 | 20~600 | 18.5 | 3880 x 2150 x 200 |

16 x 4000 | 16 | 4000 | 2°30′ | 10 | 20~800 | 37 | 4650 x 21580 x 2200 |

16 x 5000 | 16 | 5000 | 2° | 6 | 20~100 | 18.5 | 5900 x 2600 x 2700 |

16 x 6000 | 16 | 6000 | 2° | 5 | 20~1000 | 22 | 6900 x 2700 x 2700 |

20 x 2500 | 20 | 2500 | 2°30′ | 8 | 20~800 | 22 | 3440 x 2300 x 2500 |

20 x 3200 | 20 | 3200 | 2°30′ | 8 | 20~1000 | 22 | 4150 x 2350 x 2700 |

20 x 4000 | 20 | 4000 | 2°30′ | 5 | 20~1000 | 22 | 4850 x 2600 x 2400 |

20 x 6000 | 20 | 6000 | 2°30′ | 4 | 20~1000 | 37 | 6700 x 3000 x 3000 |

25 x 2500 | 25 | 2500 | 3° | 8 | 20~1000 | 37 | 3200 x 2700 x 2900 |

25 x 3200 | 25 | 3200 | 3° | 5 | 20~1000 | 37 | 4200 x 2400 x 2500 |

30 x 2500 | 30 | 2500 | 3° | 4 | 20~1000 | 40 | 3300 x 2900 x 3000 |

30 x 3200 | 30 | 3200 | 3°30′ | 4 | 20~1000 | 40 | 4200 x 2500 x 2600 |

40 x 2500 | 40 | 2500 | 4° | 3 | 20~1000 | 75 | 3200 x 3300 x 3200 |

40 x 3200 | 40 | 3200 | 4° | 3 | 20~1000 | 90 | 4300 x 3300 x 3000 |

FAQ

1. Payment Terms

T/T, L/C at sight is acceptable by us.

2. Price Terms

It is up to your requirement. EX-WORS, FOB, CIF, CFR and so on are acceptable by us.

3. Delivery Time

15 Days from our accountant confirm your deposit payment.

4. Shipment Condition

We will arrange the machine production from our accountant confirm your deposit payment. The deposit is 30% of the contract.

The balance should be paid up before loading machines.

5. Warranty

1 year quality guaranty for the main spare parts, not include quick-wears parts, like blade, punch, die and so on. If the parts of machines have problems, which are caused by its own quality, we will provide the accessories for free.