63T 2500MM steel bending machine press brake die block

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CIF |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | about 400 set/month |

| Place of Origin: | Anhui |

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | WC67Y-63T/2500 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand Name: | Durmapress |

| Nominal force: | 630KN |

| Worktable length: | 2500mm |

| Poles distance: | 1900mm |

| Throat depth: | 250mm |

| Stroke: | 100mm |

| Max open: | 320mm |

| Power: | 5.5KW |

| Dimension: | 2500*1300*2210 |

| stanless steel: | 1.5mm |

| mild steel: | 3mm |

| Production Capacity: | about 400 set/month |

| Packing: | Wooden package of the both angle notcher |

| Delivery Date: | 30 days |

Product Description

Our Company

Product Description

1. Main Features:

Streamlined design originated from EU, heat treatment of machine frame, high rigidity workbench, optional mechanical compensation device, to ensure the precision of bending

Hydraulic synchronous control and Estun NC programmable controller guarantee precise repeatability and easy use.

Integrated hydraulic system ( Germany Bosch Rexroth ) can be automatically switched to slow bending status.

X ,Y-axis realize accurate positioning function through NC E200P controller programming and servo motor.

Latest servo response hydraulic control technology, the machine tool is more stable and reliable.

Optimal parameter ratio, best core configuration guarantee stable performance and more convenient for operation

PBA series machine is equipped with single-axis backgauge system, single-axis bending angle system and V-axis compensation function combining with customized dies, any type irregular workpieces can be done

2. Main Configuration

Estun E200P controller

Controller controls and adjusts Y-axis and X-axis

Servo drive and control positioning of X-axis and Y-axis

Adopting HIWIN ball screw and linear guide rail, accuracy 0.05mm

Front supporter bracket

Germany Bosch Rexroth hydraulic valve block

Germany EMB oil tube connector

Germany Siemens main motor

France Schneider electrics

Hydraulic & electrical overload protection

Upper and lower dies(86°, R0.6mm, material: 42CrMo)

3. Safety Standard:

1.EN 12622:2009 + A1:2013 2.EN ISO 12100:2010 3.EN 60204-1:2006+A1:2009

Front Finger protection ( safety light curtain )

South Korea KACON pedal switch ( safety grade 4 )

Back metal safeguard, CE standard

Safety relay monitor pedal switch, safety protection

Safety standard ( 2006/42/EC)

4. Estun E200P NC Controller

High-definition LCD display

Control slider stop position

Backgauge control

Servo control, can realize the backgauge and high accuracy of control block.

Unilateral and bilateral location, to improve the positioning precision and reduce screw clearance.

The main action of the machine can be configured, such as fast closing, pressing, decompression, opening.

Backgauge can automatic homing.

Backgauge can be adjusted through the manual keys.

All ports can be configured directly on the device page, and the device has self-checking function.

mm / inch

Chinese / English

Features:

· The whole EU streamlined design, heat treatment rack, high rigidity worktable, optional mechanical compensation device, to achieve precision bending.

· Hydraulic synchronous control and Estun NC programmable logic controller ensure accurate repeatability and ease use.

· Integrated hydraulic system (Bosch Rexroth Germany) allows automatically switch to slow bends in a quick way.

· X axis and Y axis realize accurate positioning function by frequency converter through NC E21 system programming control.

· Cutting-edge frequency response hydraulic control technology, more stable machine tools, more reliable operation.

· The best ratio of parameters, optimal core configuration ensure stable performance, more convenient operation.

· WC67K standard single-axis back gauge system and single-axis bending angle system, you can choose to add the V-axis compensation function, and select the appropriate mold to bend complex shape workpieces easily.

| SPECIFICATIONS FOR WC67K-63T/2500mm PRESS BRAKE | |

| Nominal force | 630KN |

| Worktable length | 2500mm |

| Poles distance | 1900mm |

| Throat depth | 250mm |

| Stroke | 100mm |

| Max open | 320mm |

| Power | 5.5KW |

| Dimension | 3200*1300*2210 |

Detailed Images

Back gauge

High precistion stop finger with mutli axes backgauge

servo motor drived with high speed

Front suport and clamps

Front support on liner guide can move left and right easily, up and down by manual.

Upper die quick clamp with compensation device.

Main motor, pump and valve

Siemens main motor German brand.

Rexroth pump German brand.

Rexroth valve German brand.

Upper and down die

Machine with one set standard toolings with upper punch segmented and multi-V die in one pc.

Optional Machine Parts

World good controller, CNC X, Y1,Y2 axis Control.

Certifications

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Packing & Delivery

Packaging Details

1.Our wooden case is after fumigation treatment.Needn't timber inspection,saving shipping time.

2.All the spare parts of the machine were covered by soms softmaterials,mainly using pearl wool.

3.The outmost is wooben case with fixed formwork.

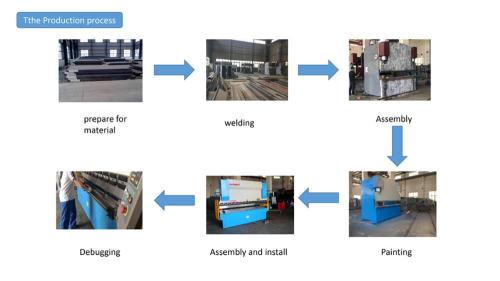

production process